ASSEMBLY

ASSEMBLY

Ballast Weight

Tractor must be stable while operating the hedge cutters under all conditions. Pay attention when operating on slopes. Front end ballast as well as rear wheel weights to counterbalance the overhang of the flail head should be added as appropriate. On steeply banked ground, it may not be sufficient to depend alone on the counterweight provided by the oil reservoir.

In addition, rear wheel track should be set as wide as possible to increase stability. It will also increase the protection to the reservoir.

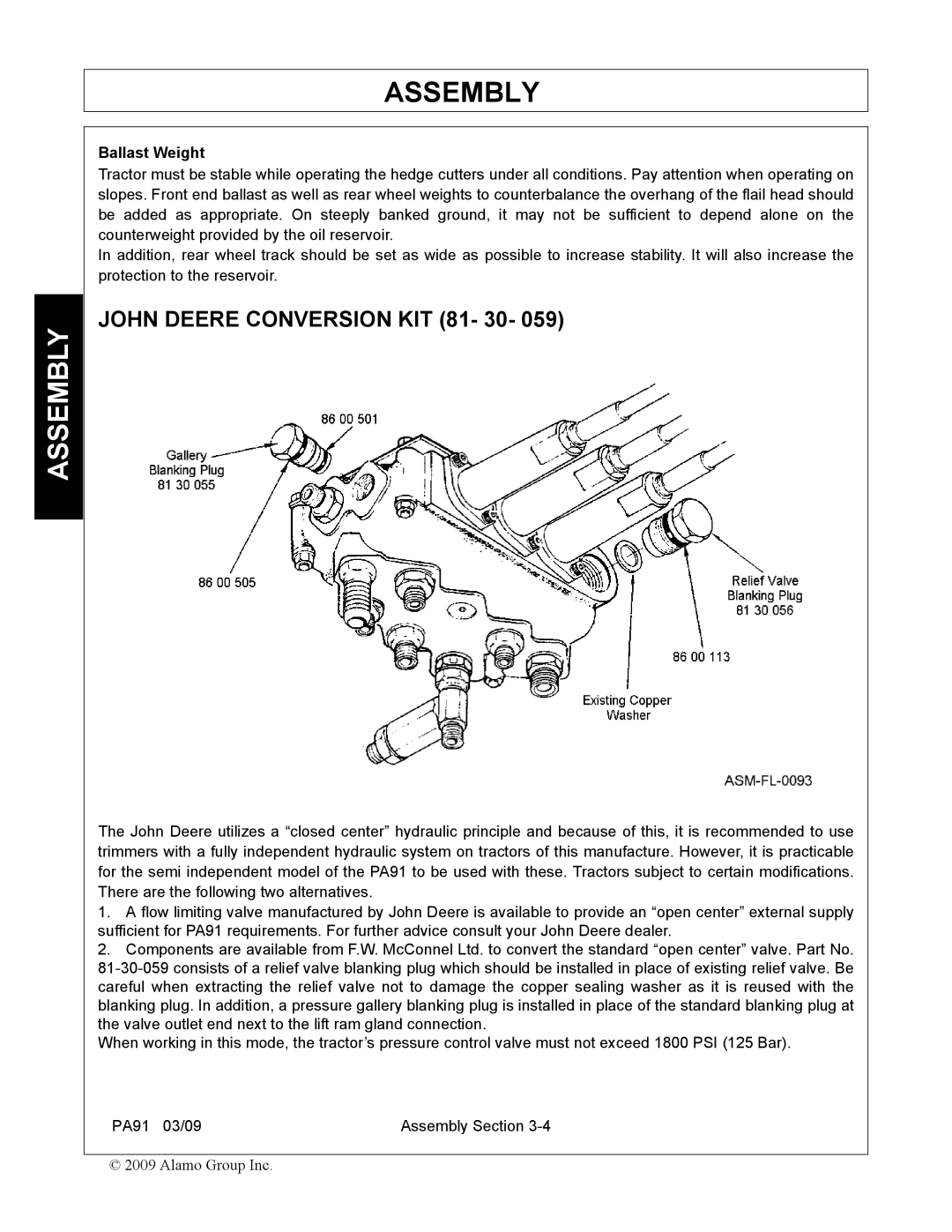

JOHN DEERE CONVERSION KIT (81- 30- 059)

The John Deere utilizes a “closed center” hydraulic principle and because of this, it is recommended to use trimmers with a fully independent hydraulic system on tractors of this manufacture. However, it is practicable for the semi independent model of the PA91 to be used with these. Tractors subject to certain modifications. There are the following two alternatives.

1.A flow limiting valve manufactured by John Deere is available to provide an “open center” external supply sufficient for PA91 requirements. For further advice consult your John Deere dealer.

2.Components are available from F.W. McConnel Ltd. to convert the standard “open center” valve. Part No.

When working in this mode, the tractor’s pressure control valve must not exceed 1800 PSI (125 Bar).

PA91 03/09 | Assembly Section |

© 2009 Alamo Group Inc.