OPERATION

7. OPERATING THE BOOM MOWER

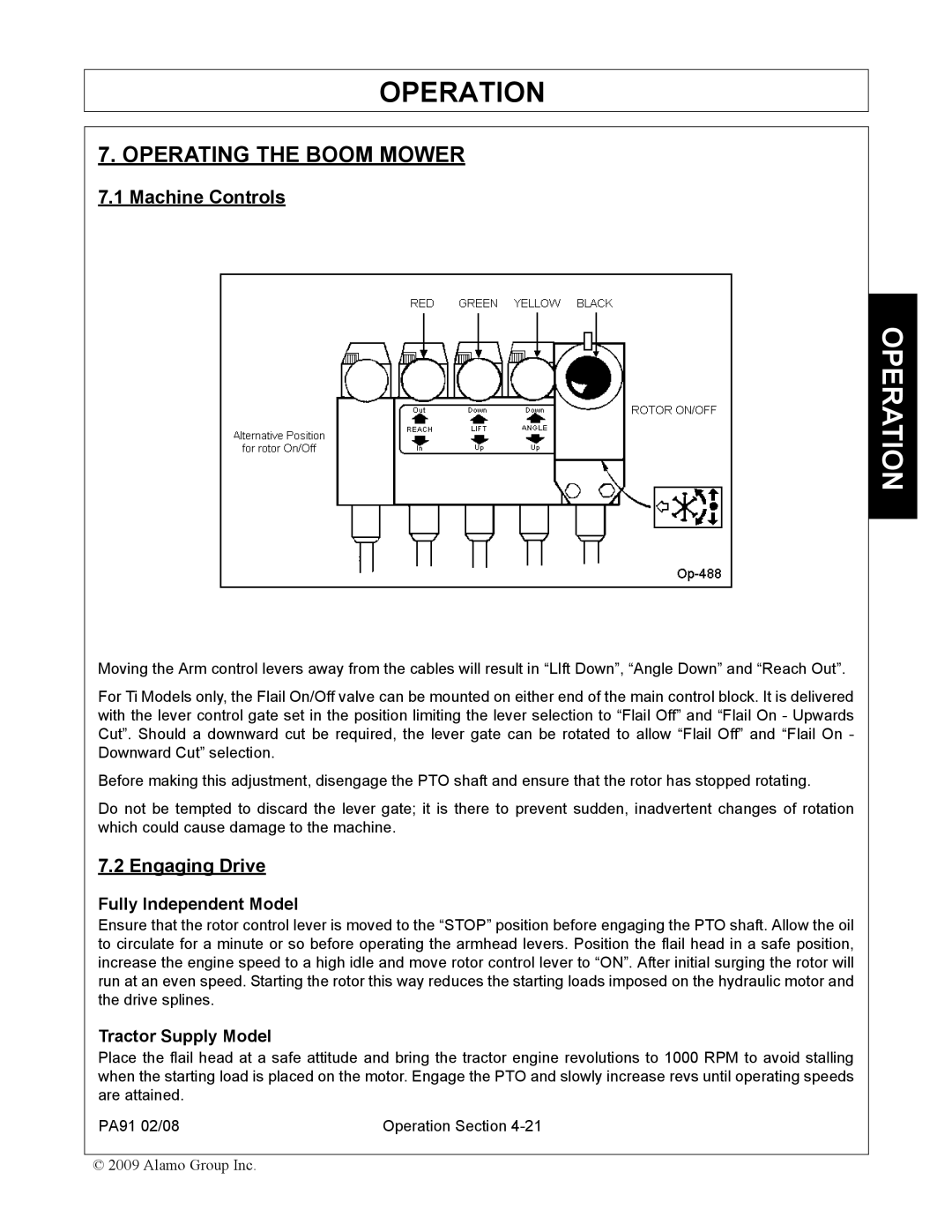

7.1 Machine Controls

Moving the Arm control levers away from the cables will result in “LIft Down”, “Angle Down” and “Reach Out”.

For Ti Models only, the Flail On/Off valve can be mounted on either end of the main control block. It is delivered with the lever control gate set in the position limiting the lever selection to “Flail Off” and “Flail On - Upwards Cut”. Should a downward cut be required, the lever gate can be rotated to allow “Flail Off” and “Flail On - Downward Cut” selection.

Before making this adjustment, disengage the PTO shaft and ensure that the rotor has stopped rotating.

Do not be tempted to discard the lever gate; it is there to prevent sudden, inadvertent changes of rotation which could cause damage to the machine.

7.2 Engaging Drive

Fully Independent Model

Ensure that the rotor control lever is moved to the “STOP” position before engaging the PTO shaft. Allow the oil to circulate for a minute or so before operating the armhead levers. Position the flail head in a safe position, increase the engine speed to a high idle and move rotor control lever to “ON”. After initial surging the rotor will run at an even speed. Starting the rotor this way reduces the starting loads imposed on the hydraulic motor and the drive splines.

Tractor Supply Model

Place the flail head at a safe attitude and bring the tractor engine revolutions to 1000 RPM to avoid stalling when the starting load is placed on the motor. Engage the PTO and slowly increase revs until operating speeds are attained.

PA91 02/08 | Operation Section |

© 2009 Alamo Group Inc.