OPERATION

OPERATION

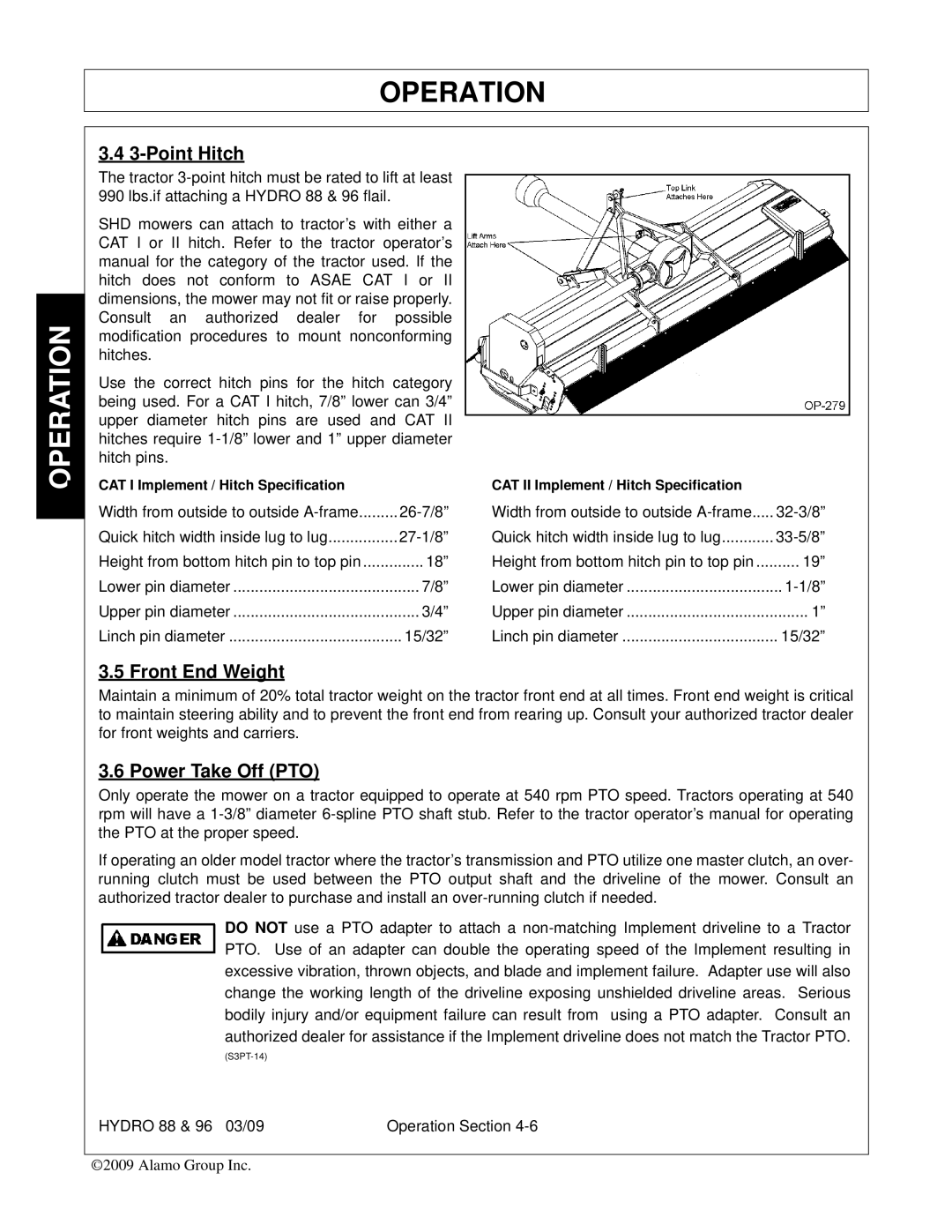

3.4 3-Point Hitch

The tractor

SHD mowers can attach to tractor’s with either a CAT I or II hitch. Refer to the tractor operator’s manual for the category of the tractor used. If the hitch does not conform to ASAE CAT I or II dimensions, the mower may not fit or raise properly. Consult an authorized dealer for possible modification procedures to mount nonconforming hitches.

Use the correct hitch pins for the hitch category being used. For a CAT I hitch, 7/8” lower can 3/4” upper diameter hitch pins are used and CAT II hitches require

CAT I Implement / Hitch Specification |

| CAT II Implement / Hitch Specification |

|

Width from outside to outside | Width from outside to outside | ||

Quick hitch width inside lug to lug |

| Quick hitch width inside lug to lug |

|

Height from bottom hitch pin to top pin | 18” | Height from bottom hitch pin to top pin | 19” |

Lower pin diameter | 7/8” | Lower pin diameter | |

Upper pin diameter | 3/4” | Upper pin diameter | 1” |

Linch pin diameter | 15/32” | Linch pin diameter | 15/32” |

3.5 Front End Weight

Maintain a minimum of 20% total tractor weight on the tractor front end at all times. Front end weight is critical to maintain steering ability and to prevent the front end from rearing up. Consult your authorized tractor dealer for front weights and carriers.

3.6 Power Take Off (PTO)

Only operate the mower on a tractor equipped to operate at 540 rpm PTO speed. Tractors operating at 540 rpm will have a

If operating an older model tractor where the tractor’s transmission and PTO utilize one master clutch, an over- running clutch must be used between the PTO output shaft and the driveline of the mower. Consult an authorized tractor dealer to purchase and install an

DO NOT use a PTO adapter to attach a

(S3PT-14)

HYDRO 88 & 96 03/09 | Operation Section |

©2009 Alamo Group Inc.