MAINTENANCE

MAINTENANCE

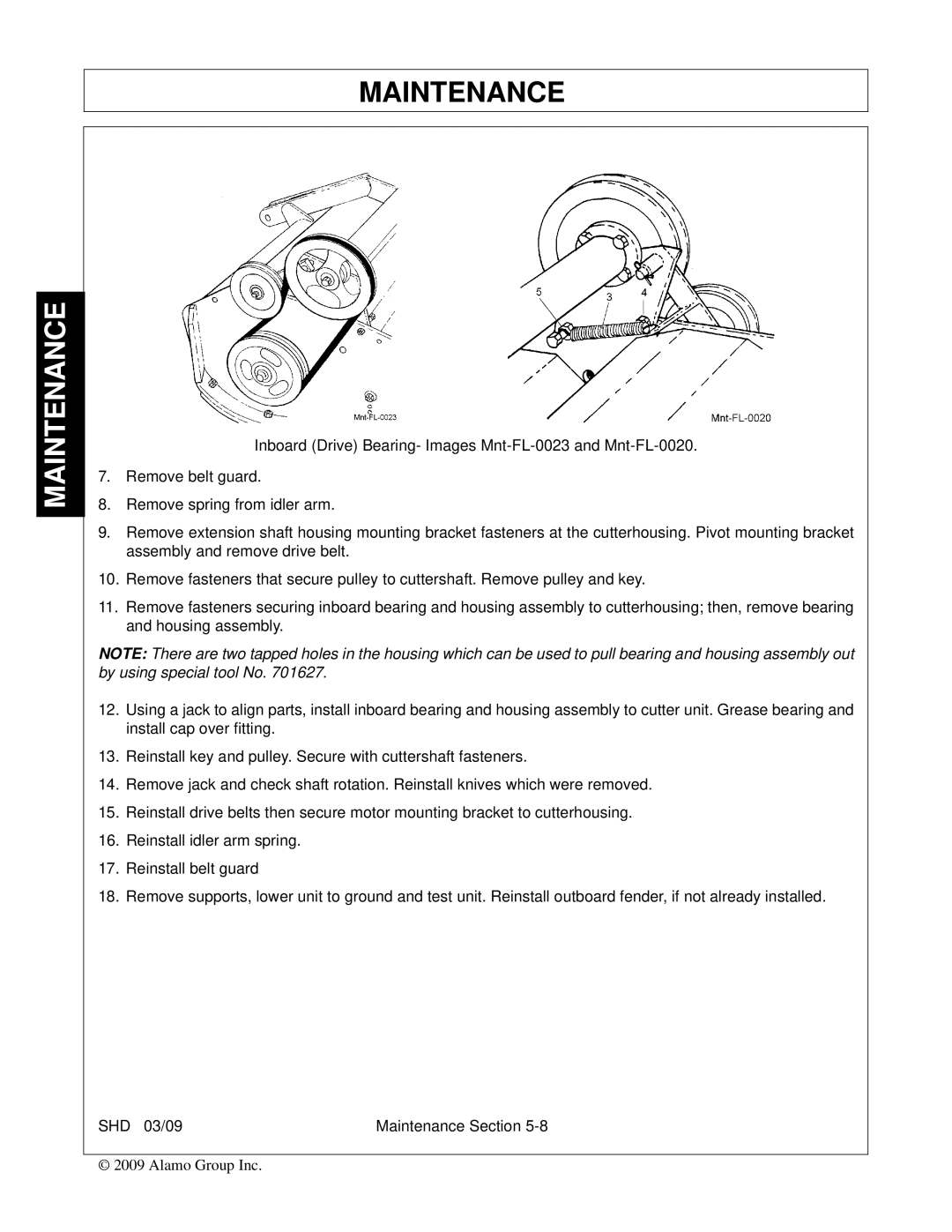

Inboard (Drive) Bearing- Images

7.Remove belt guard.

8.Remove spring from idler arm.

9.Remove extension shaft housing mounting bracket fasteners at the cutterhousing. Pivot mounting bracket assembly and remove drive belt.

10.Remove fasteners that secure pulley to cuttershaft. Remove pulley and key.

11.Remove fasteners securing inboard bearing and housing assembly to cutterhousing; then, remove bearing and housing assembly.

NOTE: There are two tapped holes in the housing which can be used to pull bearing and housing assembly out by using special tool No. 701627.

12.Using a jack to align parts, install inboard bearing and housing assembly to cutter unit. Grease bearing and install cap over fitting.

13.Reinstall key and pulley. Secure with cuttershaft fasteners.

14.Remove jack and check shaft rotation. Reinstall knives which were removed.

15.Reinstall drive belts then secure motor mounting bracket to cutterhousing.

16.Reinstall idler arm spring.

17.Reinstall belt guard

18.Remove supports, lower unit to ground and test unit. Reinstall outboard fender, if not already installed.

SHD 03/09 | Maintenance Section |

© 2009 Alamo Group Inc.