4

Liquid soap connection (option)

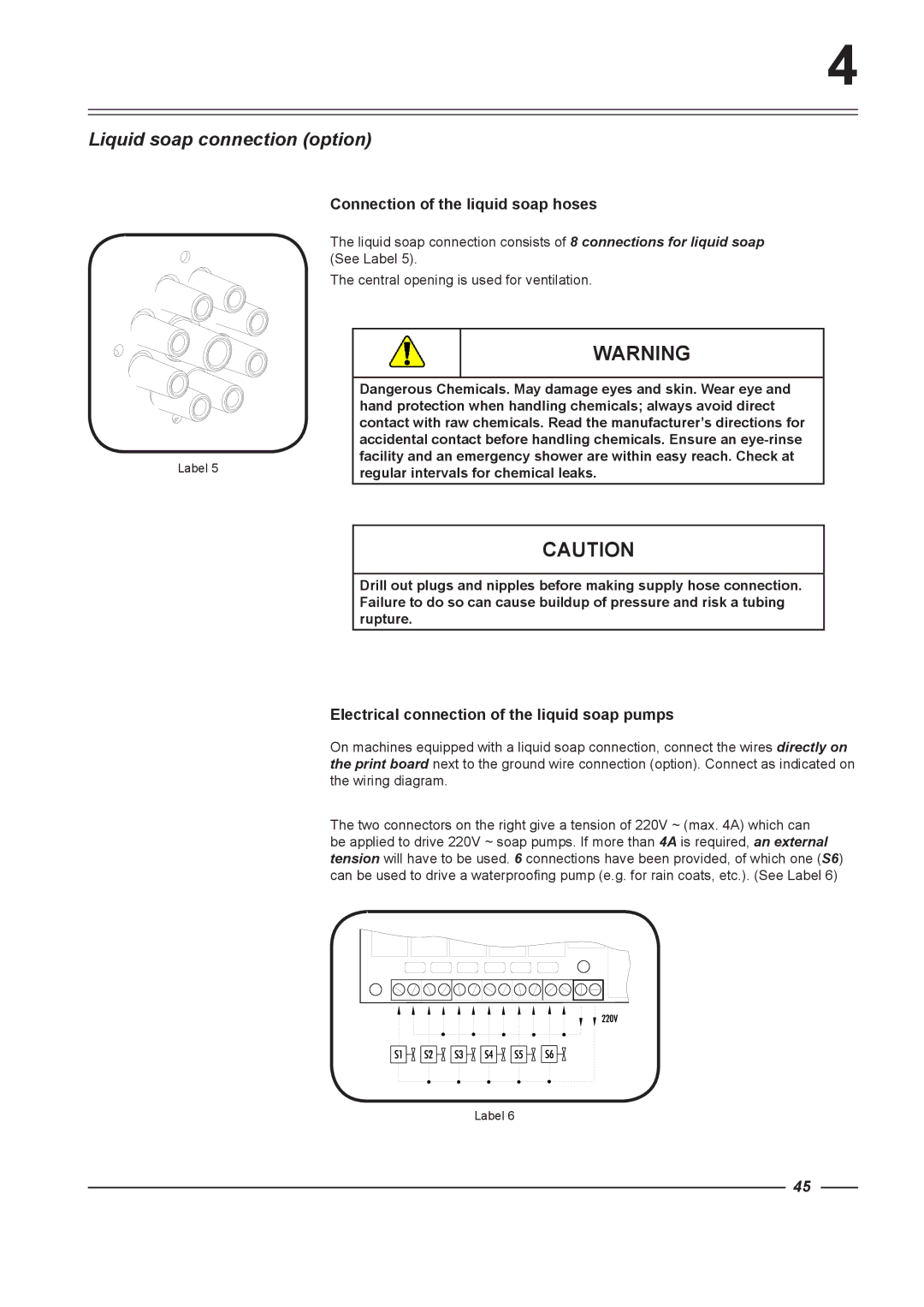

Connection of the liquid soap hoses

The liquid soap connection consists of 8 connections for liquid soap (See Label 5).

The central opening is used for ventilation.

Label 5

WARNING

Dangerous Chemicals. May damage eyes and skin. Wear eye and hand protection when handling chemicals; always avoid direct contact with raw chemicals. Read the manufacturer’s directions for accidental contact before handling chemicals. Ensure an

CAUTION

Drill out plugs and nipples before making supply hose connection. Failure to do so can cause buildup of pressure and risk a tubing rupture.

Electrical connection of the liquid soap pumps

On machines equipped with a liquid soap connection, connect the wires directly on the print board next to the ground wire connection (option). Connect as indicated on the wiring diagram.

The two connectors on the right give a tension of 220V ~ (max. 4A) which can be applied to drive 220V ~ soap pumps. If more than 4A is required, an external tension will have to be used. 6 connections have been provided, of which one (S6) can be used to drive a waterproofing pump (e.g. for rain coats, etc.). (See Label 6)

Label 6

45