Venting

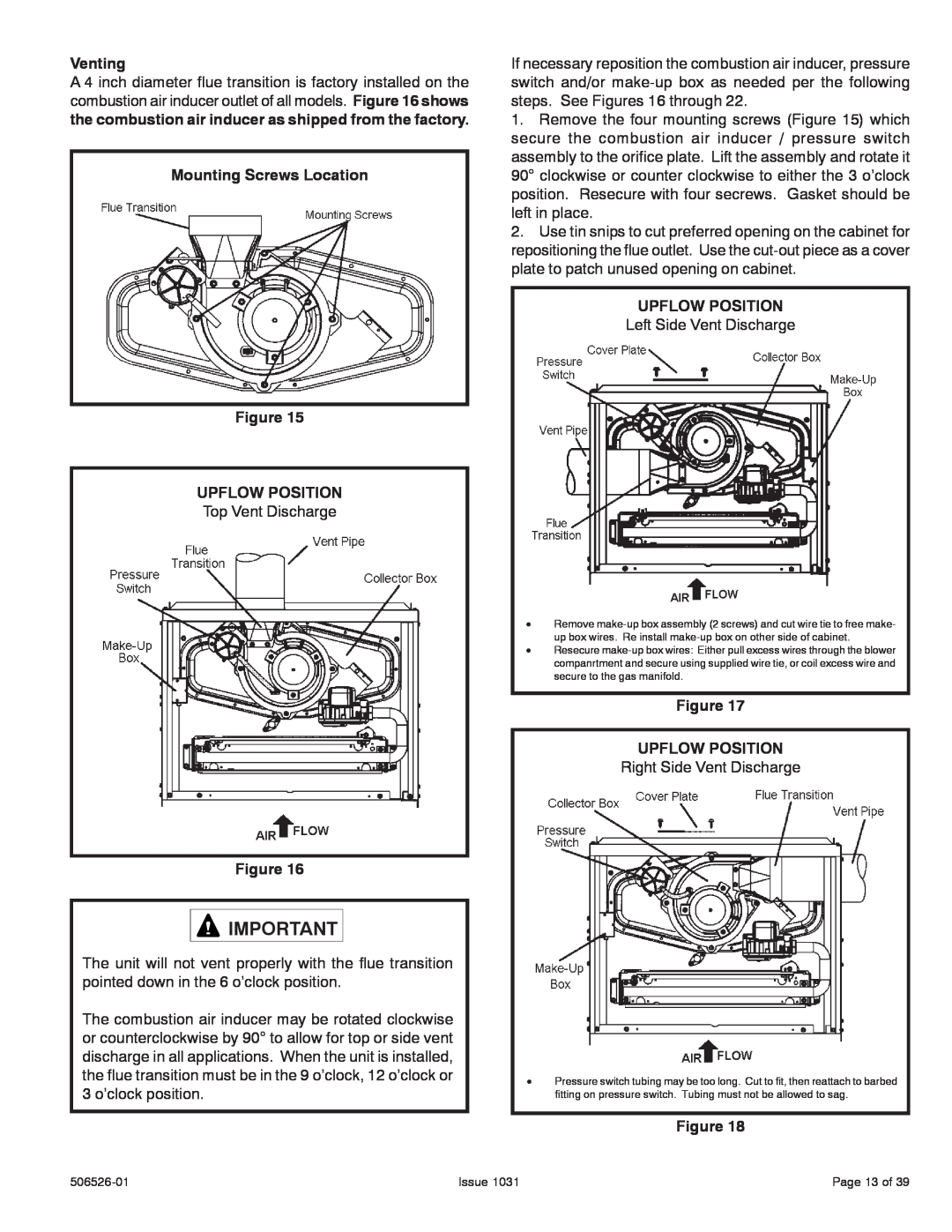

A 4 inch diameter flue transition is factory installed on the combustion air inducer outlet of all models. Figure 16 shows the combustion air inducer as shipped from the factory.

Mounting Screws Location

Figure 15

UPFLOW POSITION

Top Vent Discharge

Figure 16

![]()

![]() IMPORTANT

IMPORTANT

The unit will not vent properly with the flue transition pointed down in the 6 o’clock position.

The combustion air inducer may be rotated clockwise or counterclockwise by 90° to allow for top or side vent discharge in all applications. When the unit is installed, the flue transition must be in the 9 o’clock, 12 o’clock or 3 o’clock position.

If necessary reposition the combustion air inducer, pressure switch and/or

1.Remove the four mounting screws (Figure 15) which secure the combustion air inducer / pressure switch assembly to the orifice plate. Lift the assembly and rotate it 90° clockwise or counter clockwise to either the 3 o’clock position. Resecure with four secrews. Gasket should be left in place.

2.Use tin snips to cut preferred opening on the cabinet for repositioning the flue outlet. Use the

UPFLOW POSITION

Left Side Vent Discharge

•Remove

•Resecure

Figure 17

UPFLOW POSITION

Right Side Vent Discharge

•Pressure switch tubing may be too long. Cut to fit, then reattach to barbed fitting on pressure switch. Tubing must not be allowed to sag.

Figure 18

Issue 1031 | Page 13 of 39 |