Return Air - Upflow Applications

Return air can be brought in through the bottom or either side of the furnace installed in an upflow application. If the furnace is installed on a platform with bottom return, make an airtight seal between the bottom of the furnace and the platform to ensure that the furnace operates properly and safely. The furnace is equipped with a removable bottom panel to facilitate installation.

Markings are provided on both sides of the furnace cabinet for installations that require side return air. Cut the furnace cabinet at the maximum dimensions shown on page 2.

NOTE: 20C and 20D units that require air volumes over

1800 cfm (850 L/s) must have one of the following:

1.Single side return air with transition to accommodate 20 x 25 x 1 in. (508 x 635 x 25 mm) cleanable air filter. (Required to maintain proper air velocity.) See Figure 9.

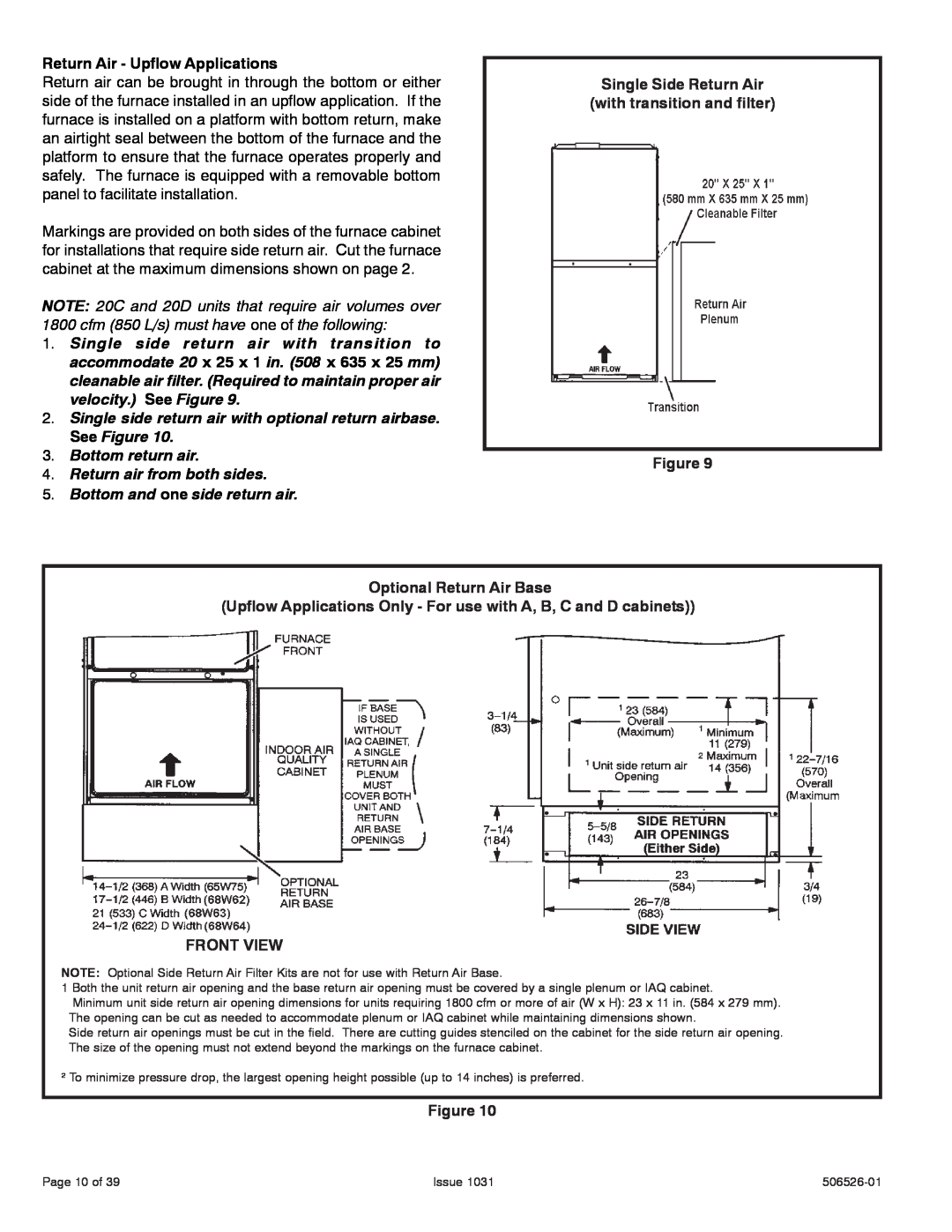

2.Single side return air with optional return airbase. See Figure 10.

3.Bottom return air.

4.Return air from both sides.

5.Bottom and one side return air.

Single Side Return Air

(with transition and filter)

Figure 9

Optional Return Air Base

(Upflow Applications Only - For use with A, B, C and D cabinets))

FRONT VIEW

NOTE: Optional Side Return Air Filter Kits are not for use with Return Air Base.

1 Both the unit return air opening and the base return air opening must be covered by a single plenum or IAQ cabinet.

Minimum unit side return air opening dimensions for units requiring 1800 cfm or more of air (W x H): 23 x 11 in. (584 x 279 mm). The opening can be cut as needed to accommodate plenum or IAQ cabinet while maintaining dimensions shown.

Side return air openings must be cut in the field. There are cutting guides stenciled on the cabinet for the side return air opening. The size of the opening must not extend beyond the markings on the furnace cabinet.

² To minimize pressure drop, the largest opening height possible (up to 14 inches) is preferred.

Figure 10

Page 10 of 39 | Issue 1031 |