4.Steam Damper Air System Connections

The

a. Air Requirements

Compressed Air Supply |

| Air Pressure | |

|

|

|

|

Normal |

| 80 PSI | 5.51 bars |

|

|

|

|

Minimum Supply |

| 70 PSI | 4.82 bars |

|

|

|

|

Maximum Supply |

| 90 PSI | 6.20 bars |

|

|

|

|

Shaded areas are stated in metric equivalents |

|

| |

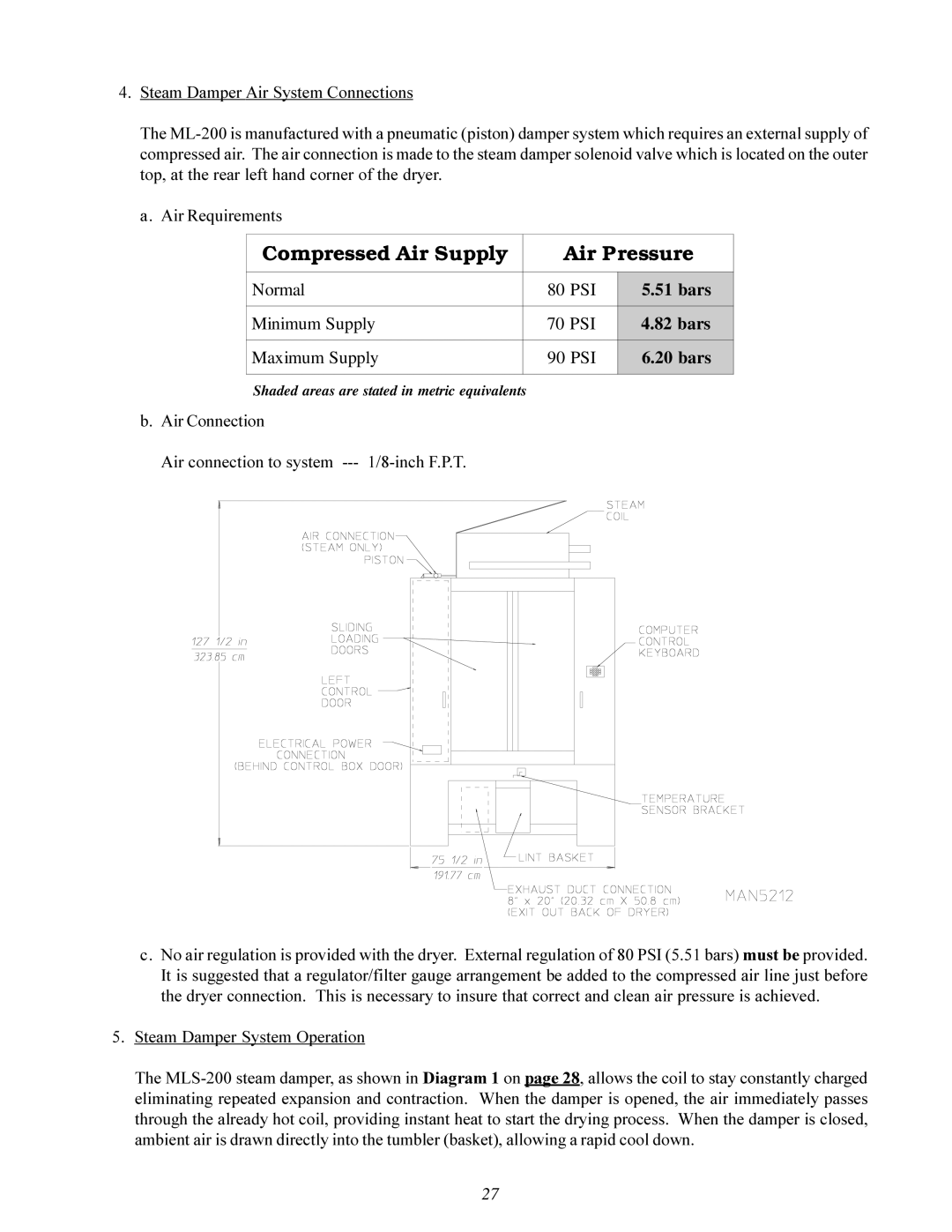

b.Air Connection

Air connection to system --- 1/8-inch F.P.T.

c.No air regulation is provided with the dryer. External regulation of 80 PSI (5.51 bars) must be provided. It is suggested that a regulator/filter gauge arrangement be added to the compressed air line just before the dryer connection. This is necessary to insure that correct and clean air pressure is achieved.

5.Steam Damper System Operation

The

27