E. STEAM DAMPER ACTUATOR SYSTEM

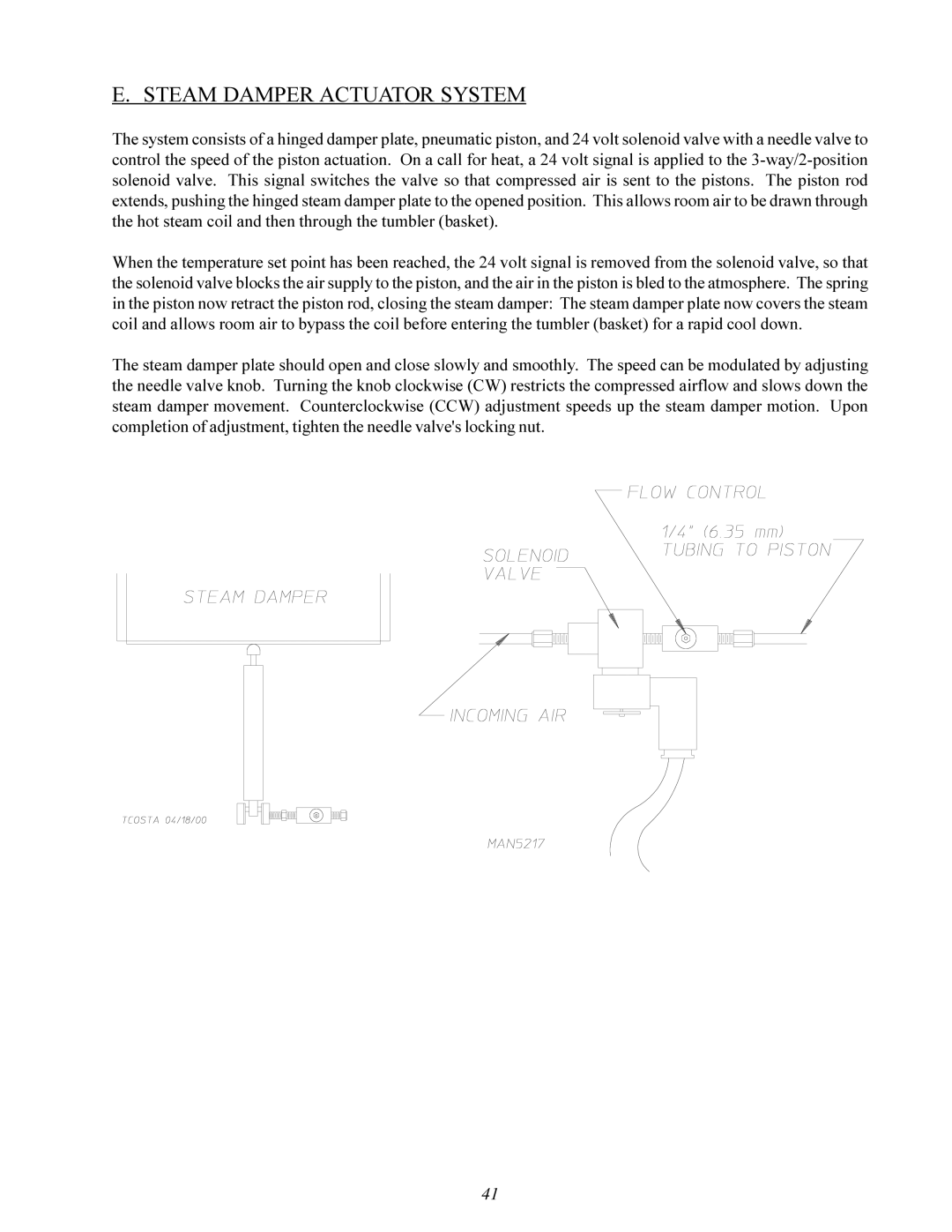

The system consists of a hinged damper plate, pneumatic piston, and 24 volt solenoid valve with a needle valve to control the speed of the piston actuation. On a call for heat, a 24 volt signal is applied to the

When the temperature set point has been reached, the 24 volt signal is removed from the solenoid valve, so that the solenoid valve blocks the air supply to the piston, and the air in the piston is bled to the atmosphere. The spring in the piston now retract the piston rod, closing the steam damper: The steam damper plate now covers the steam coil and allows room air to bypass the coil before entering the tumbler (basket) for a rapid cool down.

The steam damper plate should open and close slowly and smoothly. The speed can be modulated by adjusting the needle valve knob. Turning the knob clockwise (CW) restricts the compressed airflow and slows down the steam damper movement. Counterclockwise (CCW) adjustment speeds up the steam damper motion. Upon completion of adjustment, tighten the needle valve's locking nut.

41