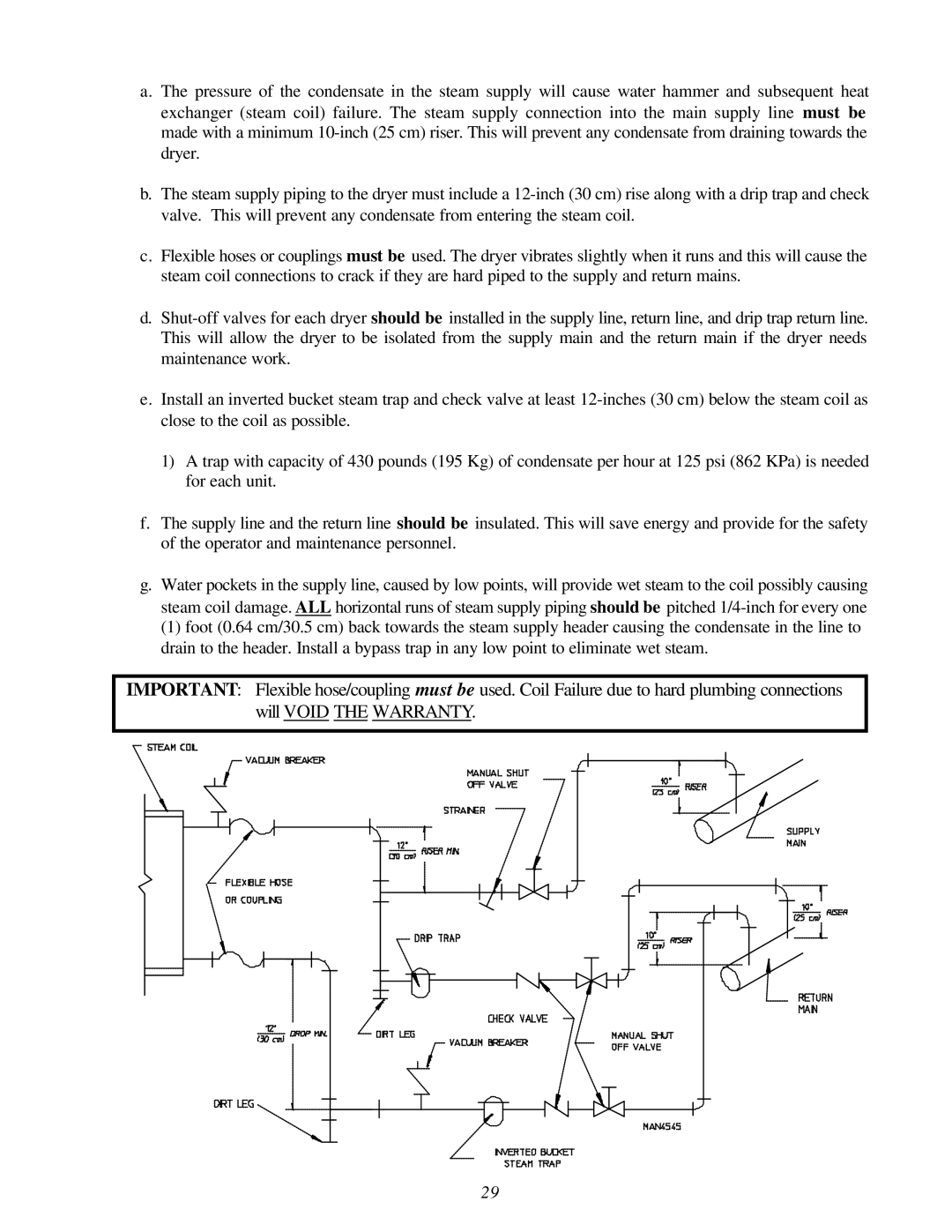

a. The pressure of the condensate in the steam supply will cause water hammer and subsequent heat exchanger (steam coil) failure. The steam supply connection into the main supply line must be made with a minimum

b.The steam supply piping to the dryer must include a

c.Flexible hoses or couplings must be used. The dryer vibrates slightly when it runs and this will cause the steam coil connections to crack if they are hard piped to the supply and return mains.

d.

e.Install an inverted bucket steam trap and check valve at least

1)A trap with capacity of 430 pounds (195 Kg) of condensate per hour at 125 psi (862 KPa) is needed for each unit.

f.The supply line and the return line should be insulated. This will save energy and provide for the safety of the operator and maintenance personnel.

g.Water pockets in the supply line, caused by low points, will provide wet steam to the coil possibly causing steam coil damage. ALL horizontal runs of steam supply piping should be pitched

(1) foot (0.64 cm/30.5 cm) back towards the steam supply header causing the condensate in the line to drain to the header. Install a bypass trap in any low point to eliminate wet steam.

IMPORTANT: Flexible hose/coupling must be used. Coil Failure due to hard plumbing connections will VOID THE WARRANTY.

29