IMPORTANT: Exhaust back pressure measured by a Magnehelic in the exhaust duct should not exceed 0.5 inches of water column (1.24 mb).

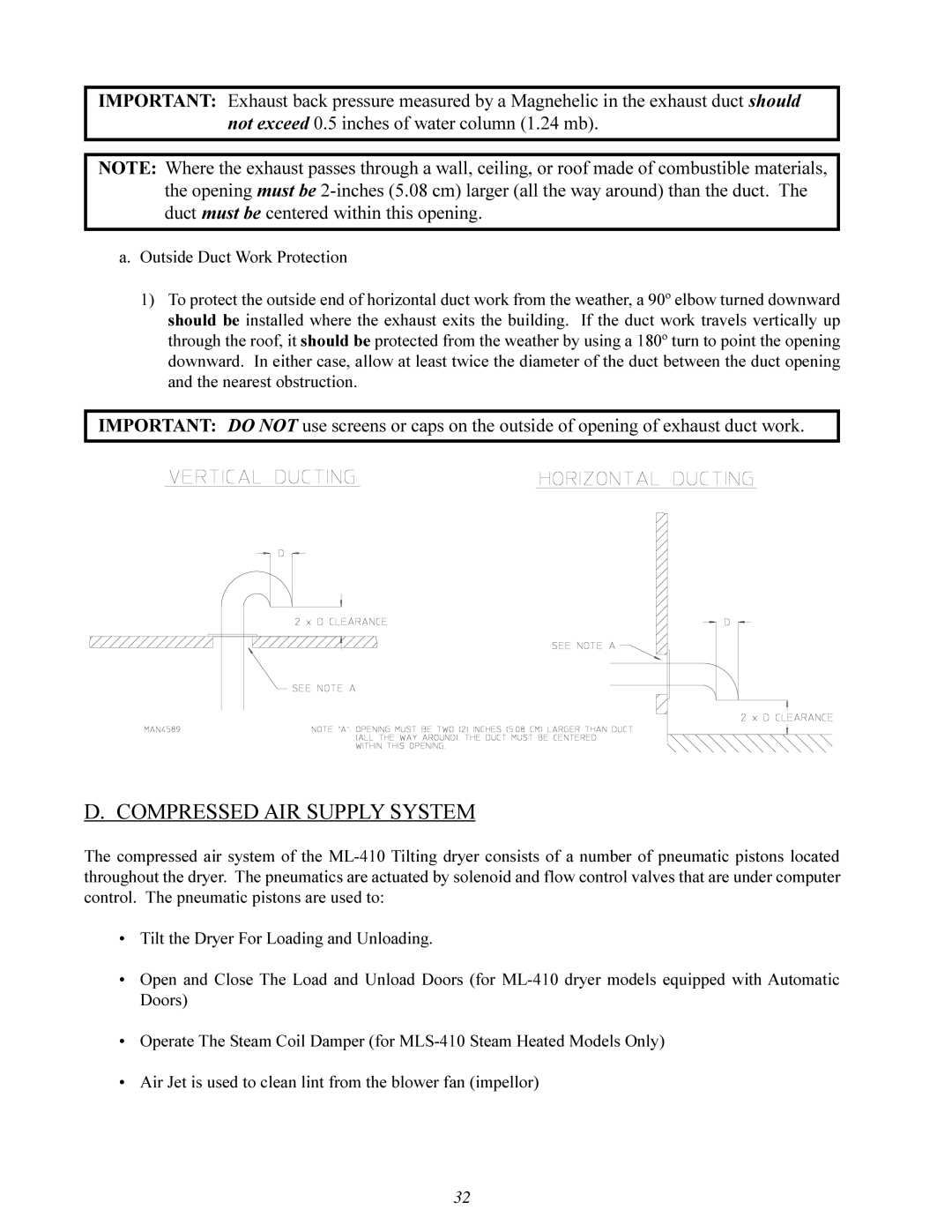

NOTE: Where the exhaust passes through a wall, ceiling, or roof made of combustible materials, the opening must be

a.Outside Duct Work Protection

1)To protect the outside end of horizontal duct work from the weather, a 90º elbow turned downward should be installed where the exhaust exits the building. If the duct work travels vertically up through the roof, it should be protected from the weather by using a 180º turn to point the opening downward. In either case, allow at least twice the diameter of the duct between the duct opening and the nearest obstruction.

IMPORTANT: DO NOT use screens or caps on the outside of opening of exhaust duct work.

D. COMPRESSED AIR SUPPLY SYSTEM

The compressed air system of the

•Tilt the Dryer For Loading and Unloading.

•Open and Close The Load and Unload Doors (for

•Operate The Steam Coil Damper (for

•Air Jet is used to clean lint from the blower fan (impellor)

32