If local codes permit, power to a gas dryer can be made by the use of a flexible U.L. listed power cord or pigtail (wire must conform to rating of dryer), or the dryer can be hard wired directly to the service breaker panel. In all cases, a strain relief must be installed where the wiring enters the dryer.

1. GAS Models Only

The only electrical input connections to the dryer are the

For gas dryers manufactured for operation at three phase (3Ø), the electrical connections are made at the power distribution block located in the service box at the rear, upper left corner of the dryer. The ground connection is made to the copper lug also provided in this box. To gain access to the service box and contactor, the service box cover must be removed.

2. ELECTRICALLY Heated Models Only

The only electrical input connections to the dryer are the

CAUTION: The dryer must be grounded. A ground lug has been provided for this purpose.

Input connection wiring must be sized properly to handle the dryer’s current draw. This information is printed on the dryers data label.

IMPORTANT: A separate circuit serving each dryer must be provided.

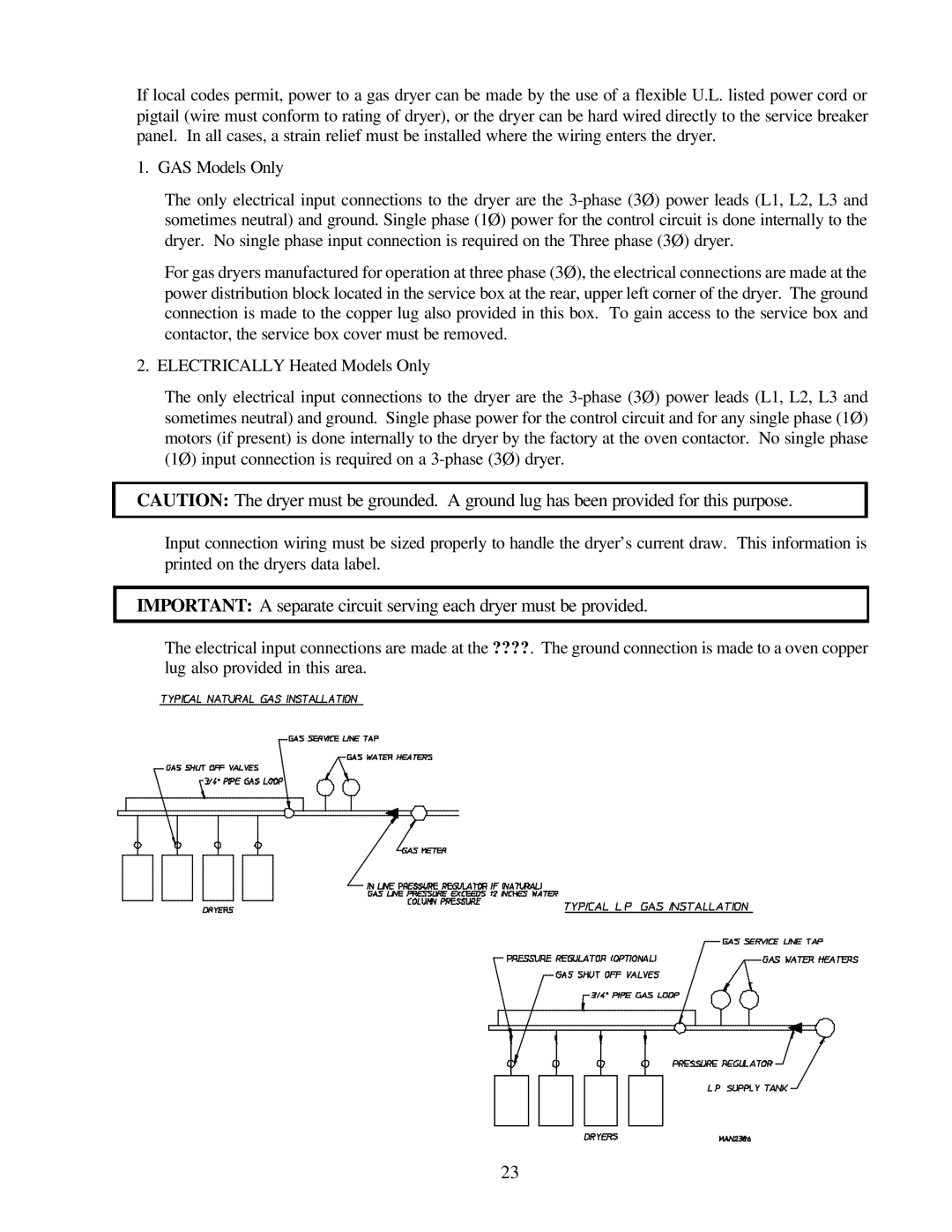

The electrical input connections are made at the ????. The ground connection is made to a oven copper lug also provided in this area.

23