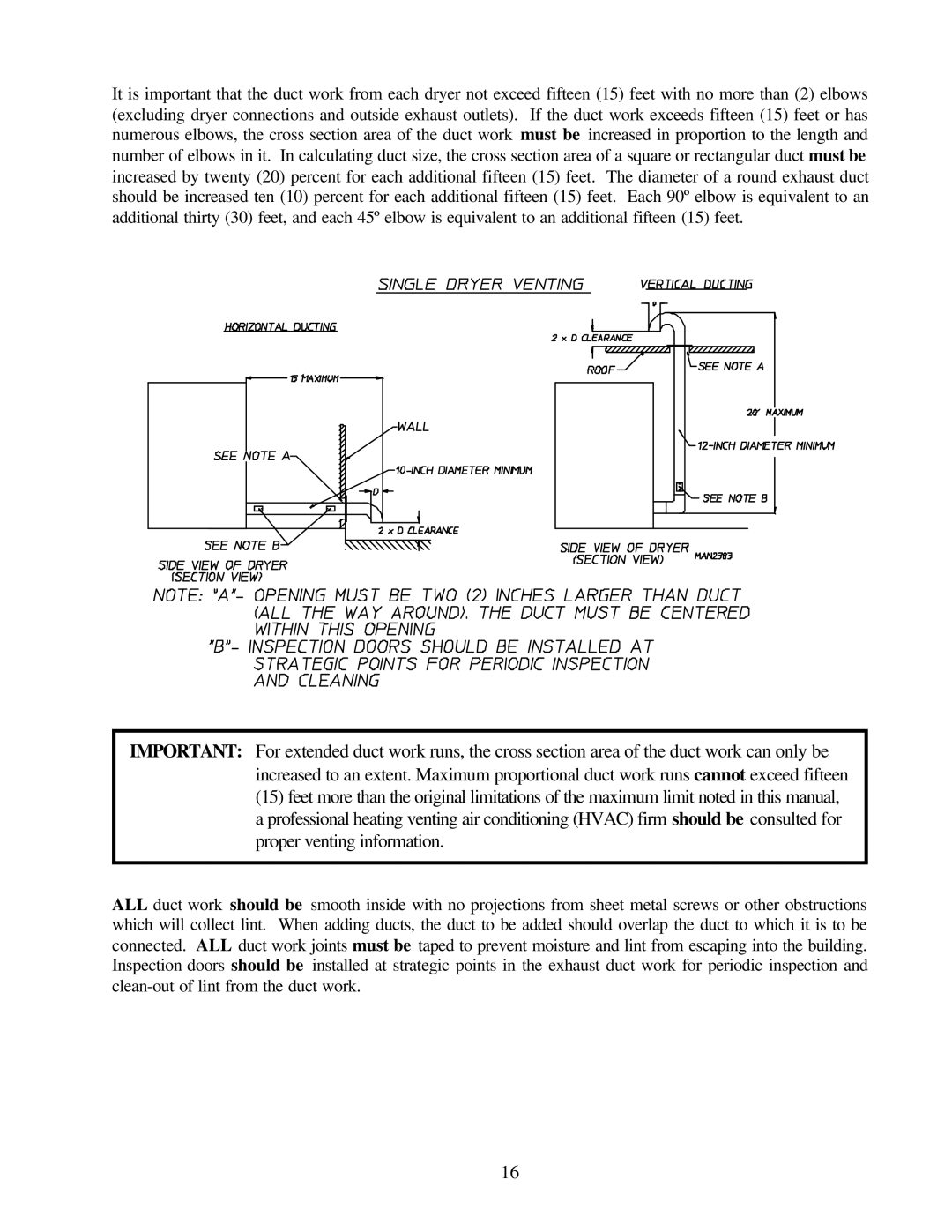

It is important that the duct work from each dryer not exceed fifteen (15) feet with no more than (2) elbows (excluding dryer connections and outside exhaust outlets). If the duct work exceeds fifteen (15) feet or has numerous elbows, the cross section area of the duct work must be increased in proportion to the length and number of elbows in it. In calculating duct size, the cross section area of a square or rectangular duct must be increased by twenty (20) percent for each additional fifteen (15) feet. The diameter of a round exhaust duct should be increased ten (10) percent for each additional fifteen (15) feet. Each 90º elbow is equivalent to an additional thirty (30) feet, and each 45º elbow is equivalent to an additional fifteen (15) feet.

IMPORTANT: For extended duct work runs, the cross section area of the duct work can only be increased to an extent. Maximum proportional duct work runs cannot exceed fifteen

(15)feet more than the original limitations of the maximum limit noted in this manual, a professional heating venting air conditioning (HVAC) firm should be consulted for proper venting information.

ALL duct work should be smooth inside with no projections from sheet metal screws or other obstructions which will collect lint. When adding ducts, the duct to be added should overlap the duct to which it is to be connected. ALL duct work joints must be taped to prevent moisture and lint from escaping into the building. Inspection doors should be installed at strategic points in the exhaust duct work for periodic inspection and

16