How to perform a leak test:

Supplies Needed for a Leak Test: Clean paint brush, water and dish washing liquid.

1)Use an LP Cylinder equipped with an OPD (Overfill Prevention Device) and have it filled at an authorized LP gas dealer by a qualified attendant.

2)Make sure all of the grill control panel knobs are turned to the “off” position and verify that the LP gas cylinder valve is closed by turning the knob on the LP gas cylinder clock wise until it stops.

3)Mix one part of water with one part of dish washing liquid.

4)Remove Fabric Panel from the front legs if necessary.

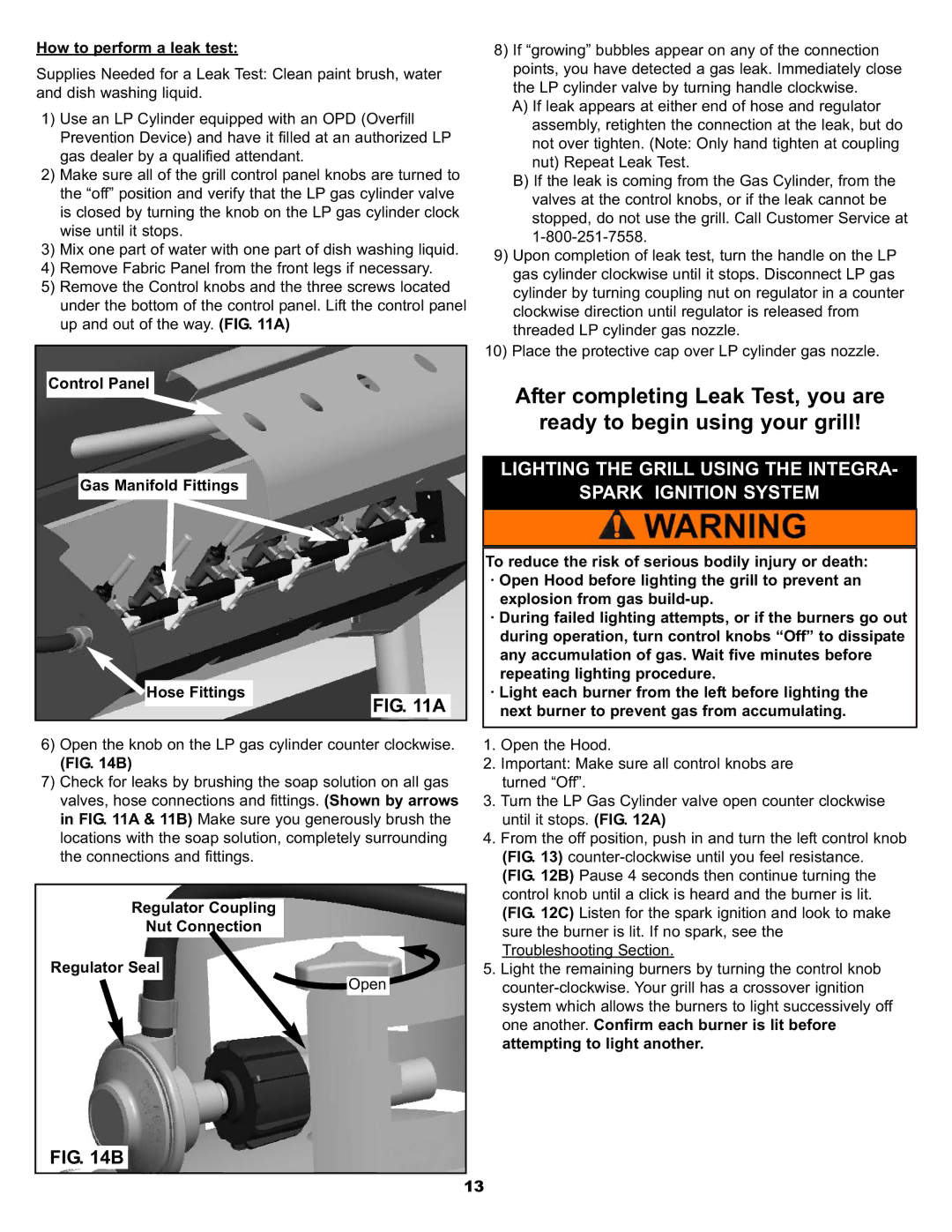

5)Remove the Control knobs and the three screws located under the bottom of the control panel. Lift the control panel up and out of the way. (FIG. 11A)

Control Panel

Gas Manifold Fittings

Hose Fittings

FIG. 11A

6)Open the knob on the LP gas cylinder counter clockwise.

(FIG. 14B)

7)Check for leaks by brushing the soap solution on all gas valves, hose connections and fittings. (Shown by arrows in FIG. 11A & 11B) Make sure you generously brush the locations with the soap solution, completely surrounding the connections and fittings.

Regulator Coupling

Nut Connection

Regulator Seal

Open

FIG. 14B

8)If “growing” bubbles appear on any of the connection points, you have detected a gas leak. Immediately close the LP cylinder valve by turning handle clockwise.

A)If leak appears at either end of hose and regulator assembly, retighten the connection at the leak, but do not over tighten. (Note: Only hand tighten at coupling nut) Repeat Leak Test.

B)If the leak is coming from the Gas Cylinder, from the valves at the control knobs, or if the leak cannot be stopped, do not use the grill. Call Customer Service at

9)Upon completion of leak test, turn the handle on the LP gas cylinder clockwise until it stops. Disconnect LP gas cylinder by turning coupling nut on regulator in a counter clockwise direction until regulator is released from threaded LP cylinder gas nozzle.

10)Place the protective cap over LP cylinder gas nozzle.

After completing Leak Test, you are

ready to begin using your grill!

LIGHTING THE GRILL USING THE INTEGRA-

SPARK IGNITION SYSTEM

To reduce the risk of serious bodily injury or death:

·Open Hood before lighting the grill to prevent an explosion from gas

·During failed lighting attempts, or if the burners go out during operation, turn control knobs “Off” to dissipate any accumulation of gas. Wait five minutes before repeating lighting procedure.

·Light each burner from the left before lighting the next burner to prevent gas from accumulating.

1.Open the Hood.

2.Important: Make sure all control knobs are turned “Off”.

3.Turn the LP Gas Cylinder valve open counter clockwise until it stops. (FIG. 12A)

4.From the off position, push in and turn the left control knob (FIG. 13)

5.Light the remaining burners by turning the control knob

13