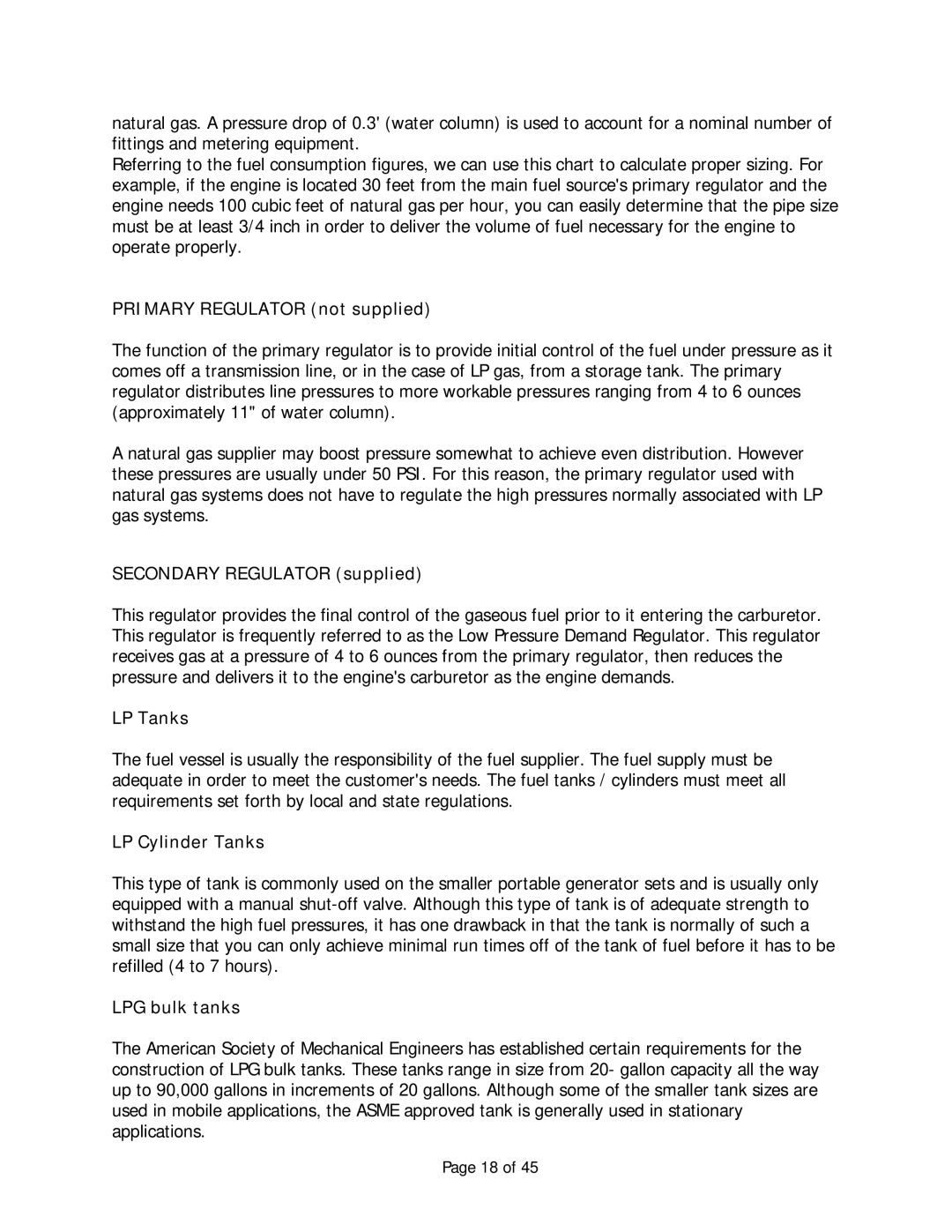

natural gas. A pressure drop of 0.3' (water column) is used to account for a nominal number of fittings and metering equipment.

Referring to the fuel consumption figures, we can use this chart to calculate proper sizing. For example, if the engine is located 30 feet from the main fuel source's primary regulator and the engine needs 100 cubic feet of natural gas per hour, you can easily determine that the pipe size must be at least 3/4 inch in order to deliver the volume of fuel necessary for the engine to operate properly.

PRIMARY REGULATOR (not supplied)

The function of the primary regulator is to provide initial control of the fuel under pressure as it comes off a transmission line, or in the case of LP gas, from a storage tank. The primary regulator distributes line pressures to more workable pressures ranging from 4 to 6 ounces (approximately 11" of water column).

A natural gas supplier may boost pressure somewhat to achieve even distribution. However these pressures are usually under 50 PSI. For this reason, the primary regulator used with natural gas systems does not have to regulate the high pressures normally associated with LP gas systems.

SECONDARY REGULATOR (supplied)

This regulator provides the final control of the gaseous fuel prior to it entering the carburetor. This regulator is frequently referred to as the Low Pressure Demand Regulator. This regulator receives gas at a pressure of 4 to 6 ounces from the primary regulator, then reduces the pressure and delivers it to the engine's carburetor as the engine demands.

LP Tanks

The fuel vessel is usually the responsibility of the fuel supplier. The fuel supply must be adequate in order to meet the customer's needs. The fuel tanks / cylinders must meet all requirements set forth by local and state regulations.

LP Cylinder Tanks

This type of tank is commonly used on the smaller portable generator sets and is usually only equipped with a manual

LPG bulk tanks

The American Society of Mechanical Engineers has established certain requirements for the construction of LPG bulk tanks. These tanks range in size from 20- gallon capacity all the way up to 90,000 gallons in increments of 20 gallons. Although some of the smaller tank sizes are used in mobile applications, the ASME approved tank is generally used in stationary applications.

Page 18 of 45