□Combustion air supply and venting have been inspected and verified to be free of obstructions and installed in accordance with all applicable codes.

□Oil nozzle has been selected correctly and securely installed in the nozzle adapter.

□Fuel unit

Figure 9.

□

□Fuel connection to nozzle line assembly is secure.

□Dimension Z has been set per the ‘Set Z Dimension’ instructions detailed earlier in this manual. The top acorn nut (Figure 16, item d) should never be loosened once the Z dimension is initially set.

□Fuel supply line is correctly installed, the oil tank is sufficiently filled, and

□Burner is securely mounted in appliance, with pressure firing plate and gasket installed for pressurized chamber application.

□Appliance has been filled with water (boilers) and controls have been operationally checked.

□Burner has been installed in accordance with appliance manufacturer’s instructions (when available).

□Also refer to appliance manufacturer’s instructions (when available) for

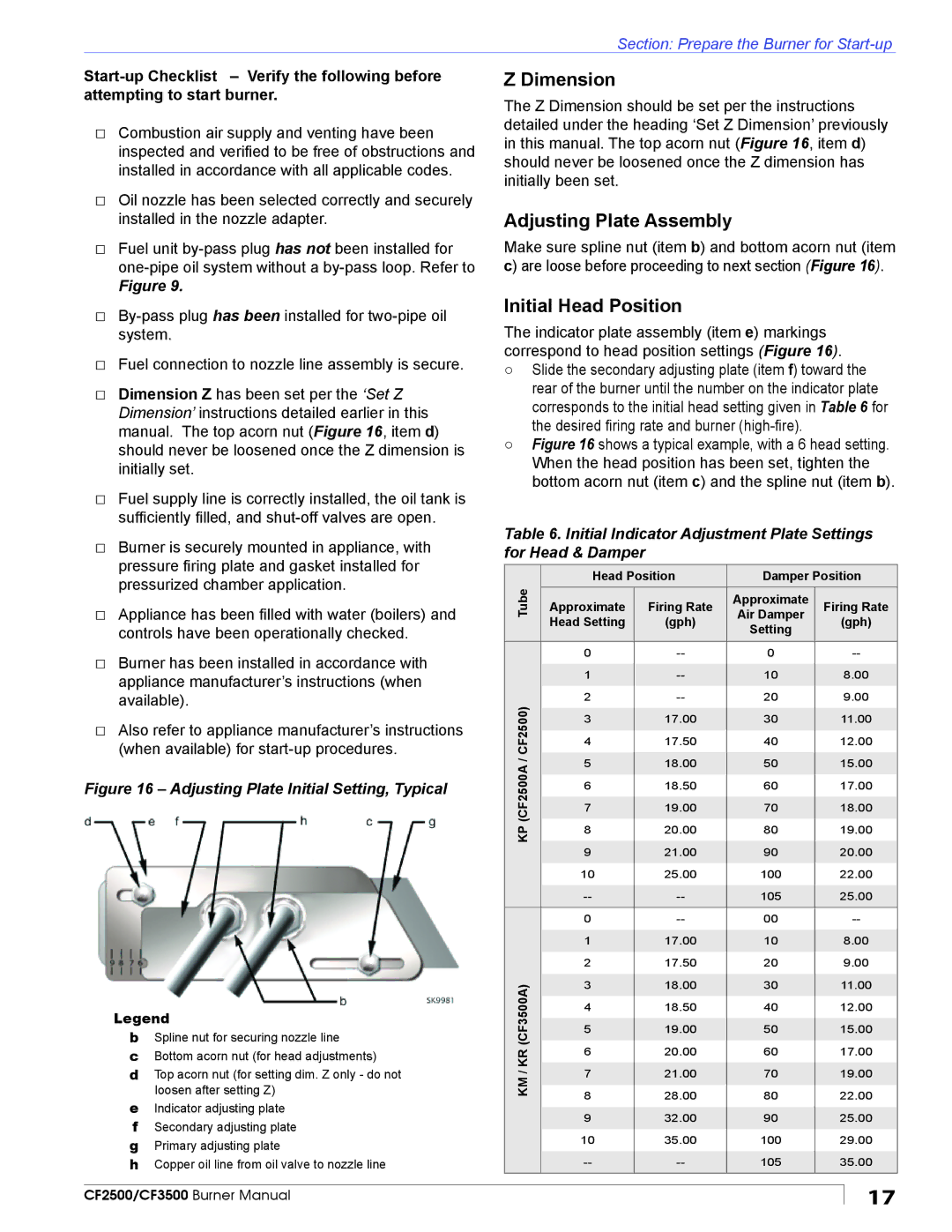

Figure 16 – Adjusting Plate Initial Setting, Typical

Legend

bSpline nut for securing nozzle line

cBottom acorn nut (for head adjustments)

dTop acorn nut (for setting dim. Z only - do not loosen after setting Z)

eIndicator adjusting plate

fSecondary adjusting plate g Primary adjusting plate

h Copper oil line from oil valve to nozzle line

CF2500/CF3500 Burner Manual

Section: Prepare the Burner for

Z Dimension

The Z Dimension should be set per the instructions detailed under the heading ‘Set Z Dimension’ previously in this manual. The top acorn nut (Figure 16, item d) should never be loosened once the Z dimension has initially been set.

Adjusting Plate Assembly

Make sure spline nut (item b) and bottom acorn nut (item c) are loose before proceeding to next section (Figure 16).

Initial Head Position

The indicator plate assembly (item e) markings correspond to head position settings (Figure 16).

○Slide the secondary adjusting plate (item f) toward the rear of the burner until the number on the indicator plate corresponds to the initial head setting given in Table 6 for the desired firing rate and burner

○Figure 16 shows a typical example, with a 6 head setting. When the head position has been set, tighten the bottom acorn nut (item c) and the spline nut (item b).

Table 6. Initial Indicator Adjustment Plate Settings for Head & Damper

Tube | Head Position | Damper Position | |||||

|

|

|

|

|

| ||

Approximate | Firing Rate | Approximate | Firing Rate | ||||

Air Damper | |||||||

| Head Setting | (gph) | (gph) | ||||

| Setting | ||||||

|

|

|

|

|

| ||

|

|

|

|

| |||

| 0 | 0 | |||||

| 1 | 10 | 8.00 | ||||

CF2500)/ | 2 | 20 | 9.00 | ||||

3 | 17.00 | 30 | 11.00 | ||||

| |||||||

| 4 | 17.50 | 40 | 12.00 | |||

(CF2500A | 5 | 18.00 | 50 | 15.00 | |||

6 | 18.50 | 60 | 17.00 | ||||

| |||||||

| 7 | 19.00 | 70 | 18.00 | |||

KP | 8 | 20.00 | 80 | 19.00 | |||

|

|

|

|

|

| ||

| 9 | 21.00 | 90 | 20.00 | |||

| 10 | 25.00 | 100 | 22.00 | |||

| 105 | 25.00 | |||||

|

|

|

|

| |||

| 0 | 00 | |||||

| 1 | 17.00 | 10 | 8.00 | |||

| 2 | 17.50 | 20 | 9.00 | |||

(CF3500A) | 3 | 18.00 | 30 | 11.00 | |||

4 | 18.50 | 40 | 12.00 | ||||

| |||||||

| 5 | 19.00 | 50 | 15.00 | |||

/ KR | 6 | 20.00 | 60 | 17.00 | |||

7 | 21.00 | 70 | 19.00 | ||||

KM | |||||||

8 | 28.00 | 80 | 22.00 | ||||

| |||||||

| 9 | 32.00 | 90 | 25.00 | |||

| 10 | 35.00 | 100 | 29.00 | |||

| 105 | 35.00 | |||||

|

|

|

|

|

|

| |

|

|

|

|

|

| 17 | |

|

|

|

|

| |||