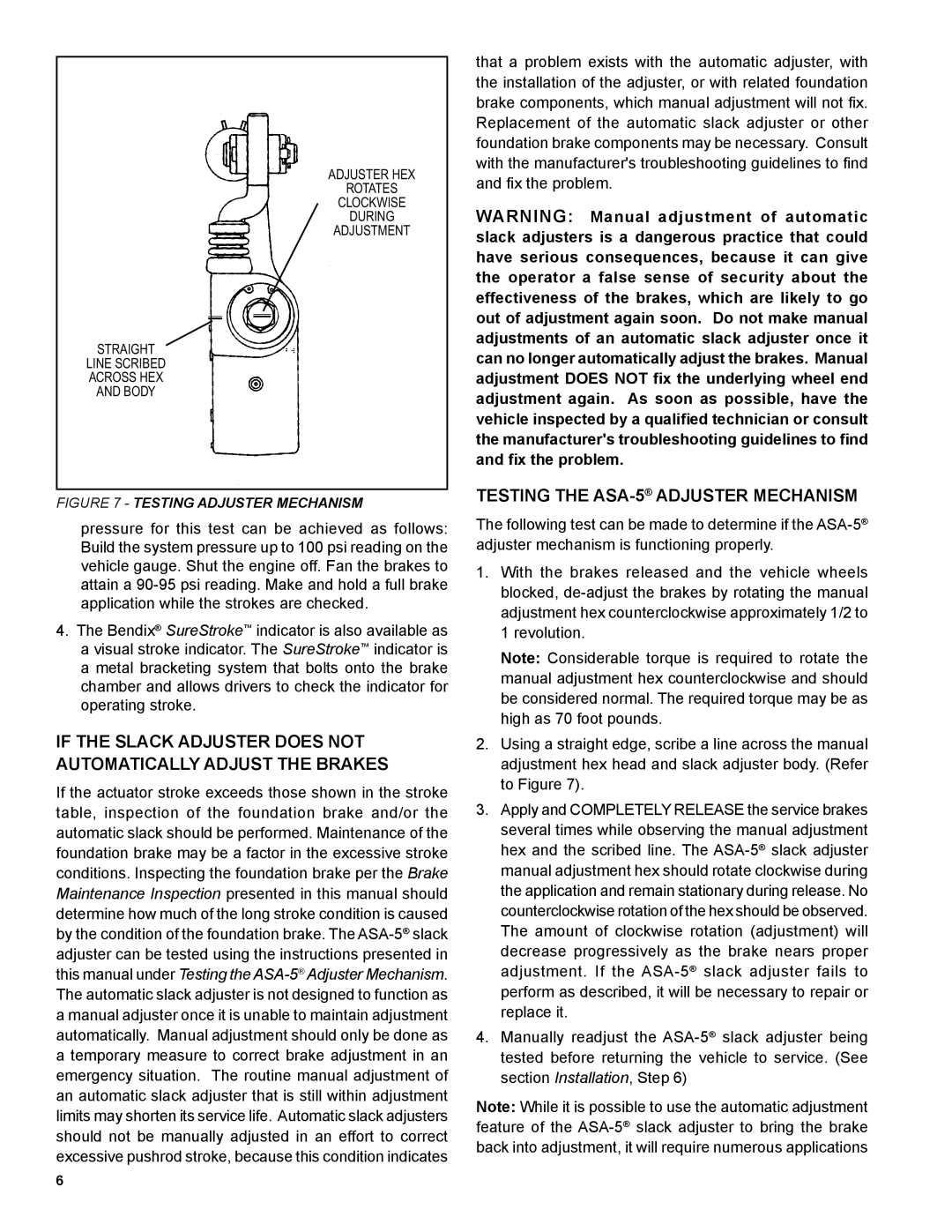

ADJUSTER HEX

ROTATES

CLOCKWISE

DURING

ADJUSTMENT

STRAIGHT

LINE SCRIBED

ACROSS HEX

AND BODY

FIGURE 7 - TESTING ADJUSTER MECHANISM

pressure for this test can be achieved as follows: Build the system pressure up to 100 psi reading on the vehicle gauge. Shut the engine off. Fan the brakes to attain a

4.The Bendix® SureStroke™ indicator is also available as a visual stroke indicator. The SureStroke™ indicator is a metal bracketing system that bolts onto the brake chamber and allows drivers to check the indicator for operating stroke.

IF THE SLACK ADJUSTER DOES NOT AUTOMATICALLY ADJUST THE BRAKES

If the actuator stroke exceeds those shown in the stroke table, inspection of the foundation brake and/or the automatic slack should be performed. Maintenance of the foundation brake may be a factor in the excessive stroke conditions. Inspecting the foundation brake per the Brake Maintenance Inspection presented in this manual should determine how much of the long stroke condition is caused by the condition of the foundation brake. The

that a problem exists with the automatic adjuster, with the installation of the adjuster, or with related foundation brake components, which manual adjustment will not fi x. Replacement of the automatic slack adjuster or other foundation brake components may be necessary. Consult with the manufacturer's troubleshooting guidelines to fi nd and fi x the problem.

WARNING: Manual adjustment of automatic slack adjusters is a dangerous practice that could have serious consequences, because it can give the operator a false sense of security about the effectiveness of the brakes, which are likely to go out of adjustment again soon. Do not make manual adjustments of an automatic slack adjuster once it can no longer automatically adjust the brakes. Manual adjustment DOES NOT fi x the underlying wheel end adjustment again. As soon as possible, have the vehicle inspected by a qualifi ed technician or consult the manufacturer's troubleshooting guidelines to fi nd and fi x the problem.

TESTING THE ASA-5® ADJUSTER MECHANISM

The following test can be made to determine if the

1.With the brakes released and the vehicle wheels blocked,

Note: Considerable torque is required to rotate the manual adjustment hex counterclockwise and should be considered normal. The required torque may be as high as 70 foot pounds.

2.Using a straight edge, scribe a line across the manual adjustment hex head and slack adjuster body. (Refer to Figure 7).

3.Apply and COMPLETELY RELEASE the service brakes several times while observing the manual adjustment hex and the scribed line. The

4.Manually readjust the

Note: While it is possible to use the automatic adjustment feature of the

6