INITIAL INSTALLATION PREPARATION

1.If necessary, carefully remove the manual or automatic slack adjuster currently installed, including the brake chamber yoke assembly.

2.Before mounting the

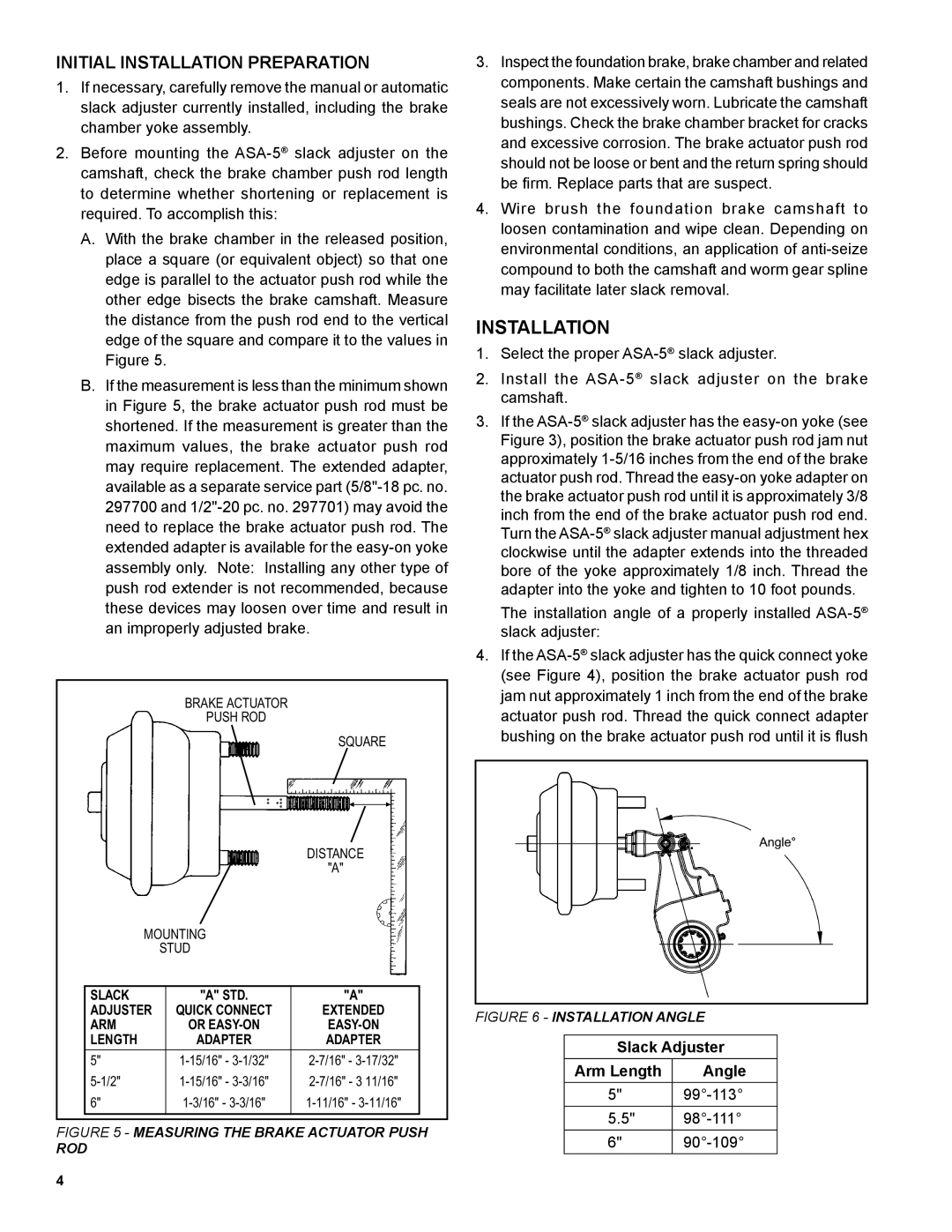

A.With the brake chamber in the released position, place a square (or equivalent object) so that one edge is parallel to the actuator push rod while the other edge bisects the brake camshaft. Measure the distance from the push rod end to the vertical edge of the square and compare it to the values in Figure 5.

B.If the measurement is less than the minimum shown in Figure 5, the brake actuator push rod must be shortened. If the measurement is greater than the maximum values, the brake actuator push rod may require replacement. The extended adapter, available as a separate service part

BRAKE ACTUATOR

PUSH ROD

SQUARE

|

|

| DISTANCE |

|

|

| "A" |

MOUNTING |

| ||

| STUD |

| |

|

|

|

|

SLACK |

| "A" STD. | "A" |

|

|

|

|

ADJUSTER |

| QUICK CONNECT | EXTENDED |

ARM |

| OR | |

LENGTH |

| ADAPTER | ADAPTER |

5" |

| ||

| |||

|

|

|

|

6" |

| ||

|

|

|

|

FIGURE 5 - MEASURING THE BRAKE ACTUATOR PUSH

ROD

3.Inspect the foundation brake, brake chamber and related components. Make certain the camshaft bushings and seals are not excessively worn. Lubricate the camshaft bushings. Check the brake chamber bracket for cracks and excessive corrosion. The brake actuator push rod should not be loose or bent and the return spring should be fi rm. Replace parts that are suspect.

4.Wire brush the foundation brake camshaft to loosen contamination and wipe clean. Depending on environmental conditions, an application of

INSTALLATION

1.Select the proper

2.Install the

3.If the

The installation angle of a properly installed

4.If the

FIGURE 6 - INSTALLATION ANGLE

Slack Adjuster

Arm Length | Angle |

|

|

5" | |

|

|

5.5" | |

|

|

6" | |

|

|

4