Electrical connection

The appliance is equipped with a 4 ft. (1.2 m.) flexible metal cable with 4 wires ready for connection to a dedicated 4 wire grounded power supply/junction box: (fig.8)

Voltage 120/208 V a.c., Frequency 60Hz. Max Current: 2800W /13,5 A

Voltage 120/240 V a.c., Frequency 60Hz. Max Current: 3700W /15,5 A

Black wire: connect to L1 (hot)

Red wire: connect to L2 (hot)

White wire: connect to N (neutral)

Green wire: connect to GND (ground)

A dedicated line and junction box should be used to connect the oven to a 20 A circuit.

Wiring diagrams Fig. 20.

Room ventilation – Location and venting.

ATTENTION: An exhaust fan may be used with the appliance; in each case it shall be installed in conformity with the national standards in force.

ATTENTION: Exhaust hood operation may affect other vented appliances; in each case it shall be installed in conformity with the national standards in force.

Conversion to different types of gas

Before carrying out any maintenance work, disconnect the appliance from the gas and electric supply. For Natural Gas fit regulator assembly described in Fig. 5. For LP Gas fit assembly described in fig. 5.

-CHANGING THE NOZZLES FOR USE WITH OTHER TYPES OF GAS: To change the nozzles of the burners use the following procedure:

Lift up the burners and unscrew the nozzles ( Fig. 9) using an adjustable spanner of 7 mm and change the nozzles with those designed for the new gas supply according to the information given in TABLE A shown below.

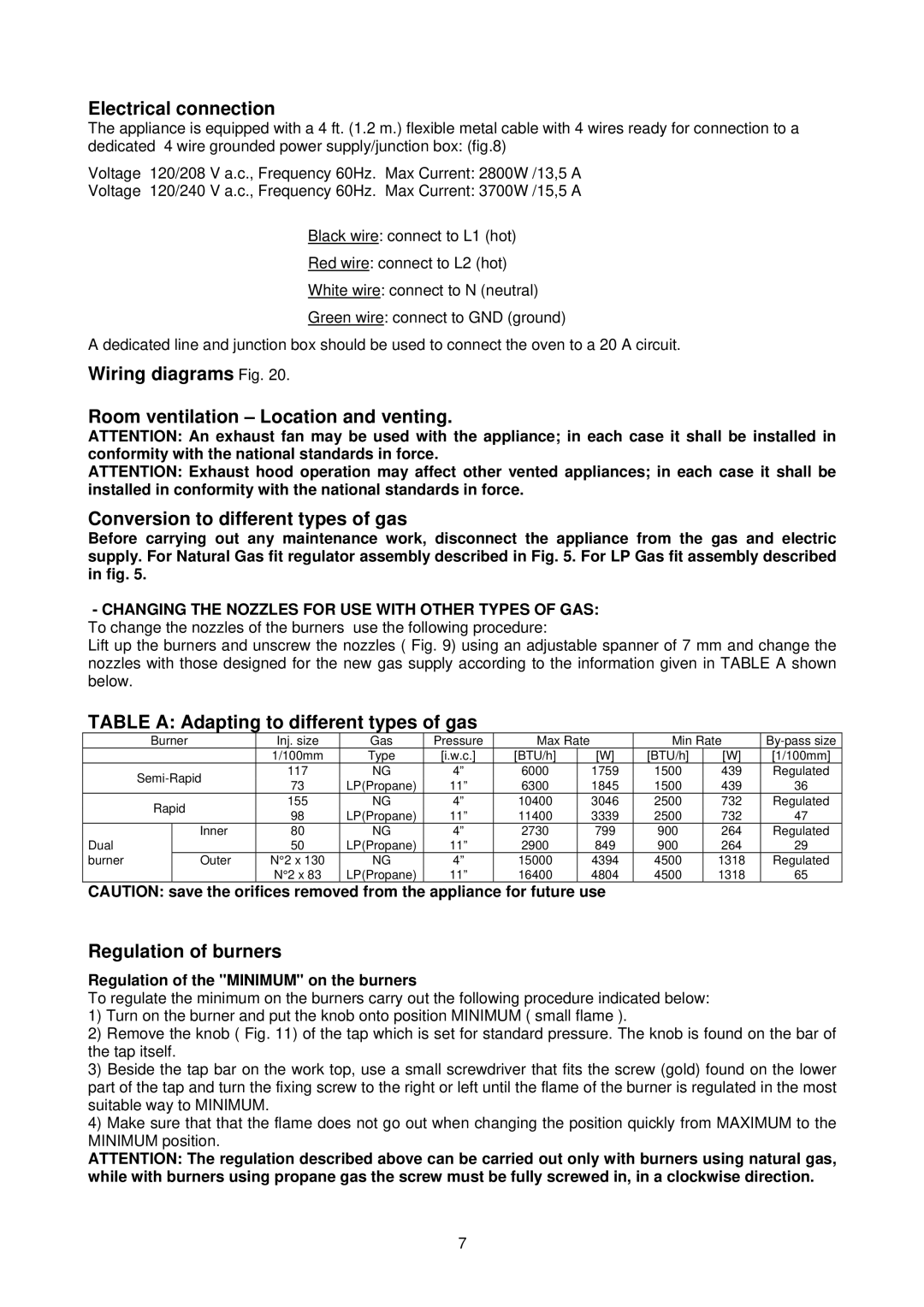

TABLE A: Adapting to different types of gas

| Burner | Inj. size | Gas | Pressure | Max Rate |

| Min Rate | |||

|

|

| 1/100mm | Type | [i.w.c.] | [BTU/h] | [W] | [BTU/h] | [W] | [1/100mm] |

| 117 | NG | 4” | 6000 | 1759 | 1500 | 439 | Regulated | ||

| 73 | LP(Propane) | 11” | 6300 | 1845 | 1500 | 439 | 36 | ||

|

|

| ||||||||

| Rapid | 155 | NG | 4” | 10400 | 3046 | 2500 | 732 | Regulated | |

| 98 | LP(Propane) | 11” | 11400 | 3339 | 2500 | 732 | 47 | ||

|

|

| ||||||||

|

| Inner | 80 | NG | 4” | 2730 | 799 | 900 | 264 | Regulated |

Dual |

|

| 50 | LP(Propane) | 11” | 2900 | 849 | 900 | 264 | 29 |

burner |

| Outer | N°2 x 130 | NG | 4” | 15000 | 4394 | 4500 | 1318 | Regulated |

|

|

| N°2 x 83 | LP(Propane) | 11” | 16400 | 4804 | 4500 | 1318 | 65 |

CAUTION: save the orifices removed from the appliance for future use

Regulation of burners

Regulation of the "MINIMUM" on the burners

To regulate the minimum on the burners carry out the following procedure indicated below:

1)Turn on the burner and put the knob onto position MINIMUM ( small flame ).

2)Remove the knob ( Fig. 11) of the tap which is set for standard pressure. The knob is found on the bar of the tap itself.

3)Beside the tap bar on the work top, use a small screwdriver that fits the screw (gold) found on the lower part of the tap and turn the fixing screw to the right or left until the flame of the burner is regulated in the most suitable way to MINIMUM.

4)Make sure that that the flame does not go out when changing the position quickly from MAXIMUM to the MINIMUM position.

ATTENTION: The regulation described above can be carried out only with burners using natural gas, while with burners using propane gas the screw must be fully screwed in, in a clockwise direction.

7