Special adjustment for measuring and adjusting CO2 levels

9Special adjustment for measuring and adjusting CO2 levels

The CO2 can only be adjusted by a certified gas technician with a calibrated CO2 analyzer.

Caution: One factor that may affect CO2 levels is improper gas pressure. Please see Chapter 2.9 for the procedure to measure gas pressure and record your findings below:

Static Gas Pressure: |

| “ WC |

P1 Operating Pressure: |

| “ WC |

| ||

|

The P1 minimum operating pressure is 5" WC for Natural Gas and 11"WC for Propane. Do not proceed in adjusting CO2 until pressure has been verified to be at or above these levels, but not to exceed 14” WC.

A. Once Pressure is good

BTurn ON/OFF switch to the OFF (O) position.

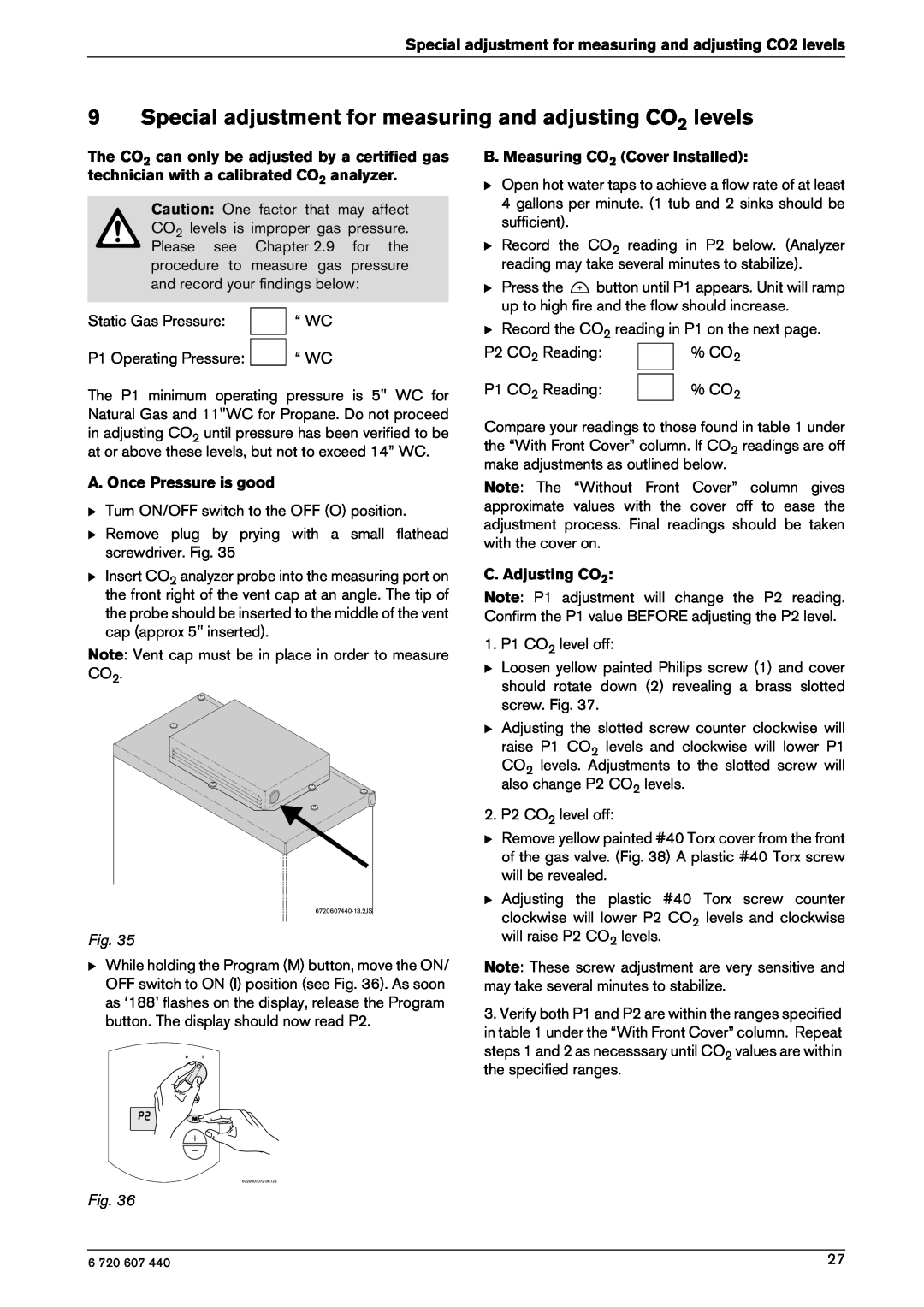

BRemove plug by prying with a small flathead screwdriver. Fig. 35

BInsert CO2 analyzer probe into the measuring port on the front right of the vent cap at an angle. The tip of the probe should be inserted to the middle of the vent cap (approx 5" inserted).

Note: Vent cap must be in place in order to measure CO2.

Fig. 35

BWhile holding the Program (M) button, move the ON/ OFF switch to ON (I) position (see Fig. 36). As soon as ‘188’ flashes on the display, release the Program button. The display should now read P2.

B. Measuring CO2 (Cover Installed):

BOpen hot water taps to achieve a flow rate of at least 4 gallons per minute. (1 tub and 2 sinks should be sufficient).

BRecord the CO2 reading in P2 below. (Analyzer reading may take several minutes to stabilize).

BPress the ![]() button until P1 appears. Unit will ramp up to high fire and the flow should increase.

button until P1 appears. Unit will ramp up to high fire and the flow should increase.

BRecord the CO2 reading in P1 on the next page.

P2 CO2 Reading: |

| % CO2 |

P1 CO2 Reading: |

| % CO2 |

|

Compare your readings to those found in table 1 under the “With Front Cover” column. If CO2 readings are off make adjustments as outlined below.

Note: The “Without Front Cover” column gives approximate values with the cover off to ease the adjustment process. Final readings should be taken with the cover on.

C. Adjusting CO2:

Note: P1 adjustment will change the P2 reading. Confirm the P1 value BEFORE adjusting the P2 level.

1. P1 CO2 level off:

BLoosen yellow painted Philips screw (1) and cover should rotate down (2) revealing a brass slotted screw. Fig. 37.

BAdjusting the slotted screw counter clockwise will

raise P1 CO2 levels and clockwise will lower P1 CO2 levels. Adjustments to the slotted screw will also change P2 CO2 levels.

2. P2 CO2 level off:

BRemove yellow painted #40 Torx cover from the front of the gas valve. (Fig. 38) A plastic #40 Torx screw will be revealed.

BAdjusting the plastic #40 Torx screw counter

clockwise will lower P2 CO2 levels and clockwise will raise P2 CO2 levels.

Note: These screw adjustment are very sensitive and may take several minutes to stabilize.

3.Verify both P1 and P2 are within the ranges specified in table 1 under the “With Front Cover” column. Repeat

steps 1 and 2 as necesssary until CO2 values are within the specified ranges.

Fig. 36

6 720 607 440 | 27 |