RESHARPENING HSS BLADES

Worn or dull HSS plane blades can be re- sharpened. The optimal blade angle of 50° should be maintained when sharpening.

Once a total of 6 mm of steel has been removed from tips of the blades, both blades must be replaced because the minimum HSS blade height is 23 mm from back to tip.

LEVELING OF HSS BLADES

3.Then gradually transfer pressure to the rear shoe, and continue planing to the end of the cut.

4.Feed the planer at a uniform and reasonable rate that does not put excessive strain on the motor or blades, (do not pull the planer back over the surface already cut.)

5.Use progressive cuts until you are near the desired depth, and then re-adjust to a shallow cut for the final pass to obtain a good surface finish.

The motor may stall if ! CAUTION improperly used or

overloaded. Reduce the pressure (feed rate) or depth of cut to prevent possible damage to the tool if the motor labors.

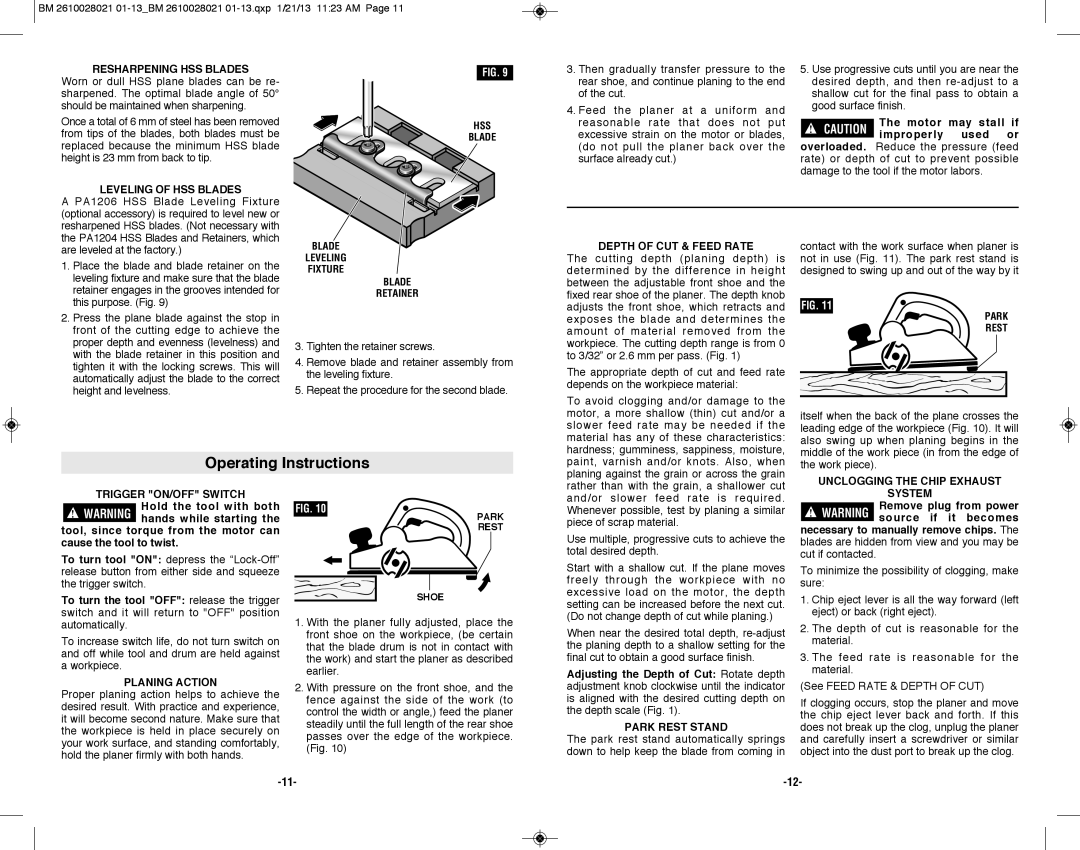

A PA1206 HSS Blade Leveling Fixture (optional accessory) is required to level new or resharpened HSS blades. (Not necessary with the PA1204 HSS Blades and Retainers, which are leveled at the factory.)

1.Place the blade and blade retainer on the leveling fixture and make sure that the blade retainer engages in the grooves intended for this purpose. (Fig. 9)

2.Press the plane blade against the stop in front of the cutting edge to achieve the proper depth and evenness (levelness) and with the blade retainer in this position and tighten it with the locking screws. This will automatically adjust the blade to the correct height and levelness.

BLADE

LEVELING

FIXTURE

BLADE

RETAINER

3.Tighten the retainer screws.

4.Remove blade and retainer assembly from the leveling fixture.

5.Repeat the procedure for the second blade.

DEPTH OF CUT & FEED RATE

The cutting depth (planing depth) is determined by the difference in height between the adjustable front shoe and the fixed rear shoe of the planer. The depth knob adjusts the front shoe, which retracts and exposes the blade and determines the amount of material removed from the workpiece. The cutting depth range is from 0 to 3/32” or 2.6 mm per pass. (Fig. 1)

The appropriate depth of cut and feed rate depends on the workpiece material:

contact with the work surface when planer is not in use (Fig. 11). The park rest stand is designed to swing up and out of the way by it

FIG. 11

PARK

REST

Operating Instructions

To avoid clogging and/or damage to the motor, a more shallow (thin) cut and/or a slower feed rate may be needed if the material has any of these characteristics: hardness; gumminess, sappiness, moisture, paint, varnish and/or knots. Also, when planing against the grain or across the grain rather than with the grain, a shallower cut

itself when the back of the plane crosses the leading edge of the workpiece (Fig. 10). It will also swing up when planing begins in the middle of the work piece (in from the edge of the work piece).

UNCLOGGING THE CHIP ExHAUST

TRIGGER "ON/OFF" SWITCH Hold the tool with both hands while starting the

tool, since torque from the motor can cause the tool to twist.

To turn tool "ON": depress the “Lock-Off” release button from either side and squeeze the trigger switch.

To turn the tool "OFF": release the trigger switch and it will return to "OFF" position automatically.

To increase switch life, do not turn switch on and off while tool and drum are held against a workpiece.

PLANING ACTION

Proper planing action helps to achieve the desired result. With practice and experience, it will become second nature. Make sure that the workpiece is held in place securely on your work surface, and standing comfortably, hold the planer firmly with both hands.

FIG. 10

PARK

REST

SHOE

1.With the planer fully adjusted, place the front shoe on the workpiece, (be certain that the blade drum is not in contact with the work) and start the planer as described earlier.

2.With pressure on the front shoe, and the fence against the side of the work (to control the width or angle,) feed the planer steadily until the full length of the rear shoe passes over the edge of the workpiece. (Fig. 10)

and/or slower feed rate is required. Whenever possible, test by planing a similar piece of scrap material.

Use multiple, progressive cuts to achieve the total desired depth.

Start with a shallow cut. If the plane moves freely through the workpiece with no excessive load on the motor, the depth setting can be increased before the next cut. (Do not change depth of cut while planing.)

When near the desired total depth, re-adjust the planing depth to a shallow setting for the final cut to obtain a good surface finish.

Adjusting the Depth of Cut: Rotate depth adjustment knob clockwise until the indicator is aligned with the desired cutting depth on the depth scale (Fig. 1).

PARK REST STAND

The park rest stand automatically springs down to help keep the blade from coming in

SYSTEM

Remove plug from power ! WARNING source if it becomes

necessary to manually remove chips. The blades are hidden from view and you may be cut if contacted.

To minimize the possibility of clogging, make sure:

1.Chip eject lever is all the way forward (left eject) or back (right eject).

2.The depth of cut is reasonable for the material.

3.The feed rate is reasonable for the material.

(See FEED RATE & DEPTH OF CUT)

If clogging occurs, stop the planer and move the chip eject lever back and forth. If this does not break up the clog, unplug the planer and carefully insert a screwdriver or similar object into the dust port to break up the clog.