stability and protection when cutting materials that are up to 3-1/4" wide.

Note: When used for rabbeting, the fence must be attached to the left side of the tool. (Fig. 1).

Installing the guide fence: Place the wing knob through the appropriate hole in the guide bracket and screw into preferred side of the housing. Securely tighten wing knob. Setting the cutting width: Place wing knob through the appropriate fence arm and slide along the guide bracket to the desired position. Securely tighten wing knob. Be certain that the flat washer (supplied) is fitted between the bottom of the guide fence and wing knob or the guide fence is likely to slip.

DELUxE GUIDE FENCE

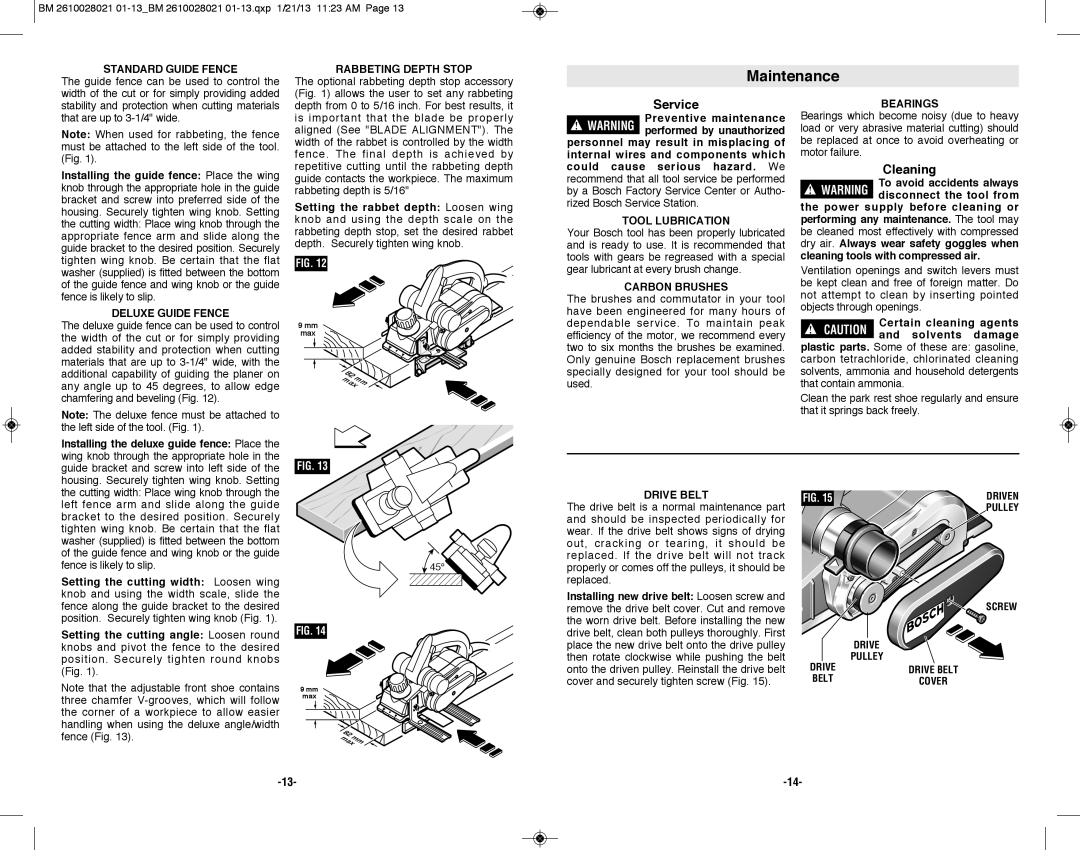

The deluxe guide fence can be used to control the width of the cut or for simply providing added stability and protection when cutting materials that are up to 3-1/4" wide, with the additional capability of guiding the planer on any angle up to 45 degrees, to allow edge chamfering and beveling (Fig. 12).

Note: The deluxe fence must be attached to the left side of the tool. (Fig. 1).

depth from 0 to 5/16 inch. For best results, it is important that the blade be properly aligned (See "BLADE ALIGNMENT"). The width of the rabbet is controlled by the width fence. The final depth is achieved by repetitive cutting until the rabbeting depth guide contacts the workpiece. The maximum rabbeting depth is 5/16"

Setting the rabbet depth: Loosen wing knob and using the depth scale on the rabbeting depth stop, set the desired rabbet depth. Securely tighten wing knob.

FIG. 12

9 mm

max

Service

Preventive maintenance

!WARNING performed by unauthorized per so n nel may result in misplacing of internal wires and components which could cause serious hazard. We recommend that all tool service be performed by a Bosch Factory Service Center or Autho- rized Bosch Service Station.

TOOL LUBRICATION

Your Bosch tool has been properly lubricated and is ready to use. It is recommended that tools with gears be regreased with a special gear lubricant at every brush change.

CARBON BRUSHES

The brushes and commutator in your tool have been engineered for many hours of dependable service. To maintain peak efficiency of the motor, we recommend every two to six months the brush es be examined. Only genuine Bosch replace ment brushes specially designed for your tool should be used.

BEARINGS

Bearings which become noisy (due to heavy load or very abrasive material cut ing)t should be replaced at once to avoid overheating or motor failure.

Cleaning

To avoid accidents always dis connect the tool from the power supply before cleaning or

performing any main tenance. The tool may be cleaned most effectively with compressed dry air. Always wear safety gog gles when cleaning tools with compressed air.

Ventilation openings and switch levers must be kept clean and free of foreign matter. Do not at tempt to clean by inserting pointed objects through openings.

Certain cleaning agents and sol vents damage plastic parts. Some of these are: gasoline,

carbon tetrachlo ride, chlo rinated cleaning solvents, ammonia and house oldh detergents that contain ammonia.

Clean the park rest shoe regularly and ensure that it springs back freely.

Installing the deluxe guide fence: Place the wing knob through the appropriate hole in the guide bracket and screw into left side of the housing. Securely tighten wing knob. Setting the cutting width: Place wing knob through the left fence arm and slide along the guide bracket to the desired position. Securely tighten wing knob. Be certain that the flat washer (supplied) is fitted between the bottom of the guide fence and wing knob or the guide fence is likely to slip.

Setting the cutting width: Loosen wing knob and using the width scale, slide the fence along the guide bracket to the desired position. Securely tighten wing knob (Fig. 1).

Setting the cutting angle: Loosen round knobs and pivot the fence to the desired position. Securely tighten round knobs (Fig. 1).

Note that the adjustable front shoe contains three chamfer V-grooves, which will follow the corner of a workpiece to allow easier handling when using the deluxe angle/width fence (Fig. 13).

FIG. 13

45°

FIG. 14

9mm max

82 ma mm x

DRIVE BELT

The drive belt is a normal maintenance part and should be inspected periodically for wear. If the drive belt shows signs of drying out, cracking or tearing, it should be replaced. If the drive belt will not track properly or comes off the pulleys, it should be replaced.

Installing new drive belt: Loosen screw and remove the drive belt cover. Cut and remove the worn drive belt. Before installing the new drive belt, clean both pulleys thoroughly. First place the new drive belt onto the drive pulley then rotate clockwise while pushing the belt onto the driven pulley. Reinstall the drive belt cover and securely tighten screw (Fig. 15).

SCREW

| DRIVE |

DRIVE | PULLEY |

DRIVE BELT |

BELT | COVER |