significant impact, the user should check calibration by following these steps:

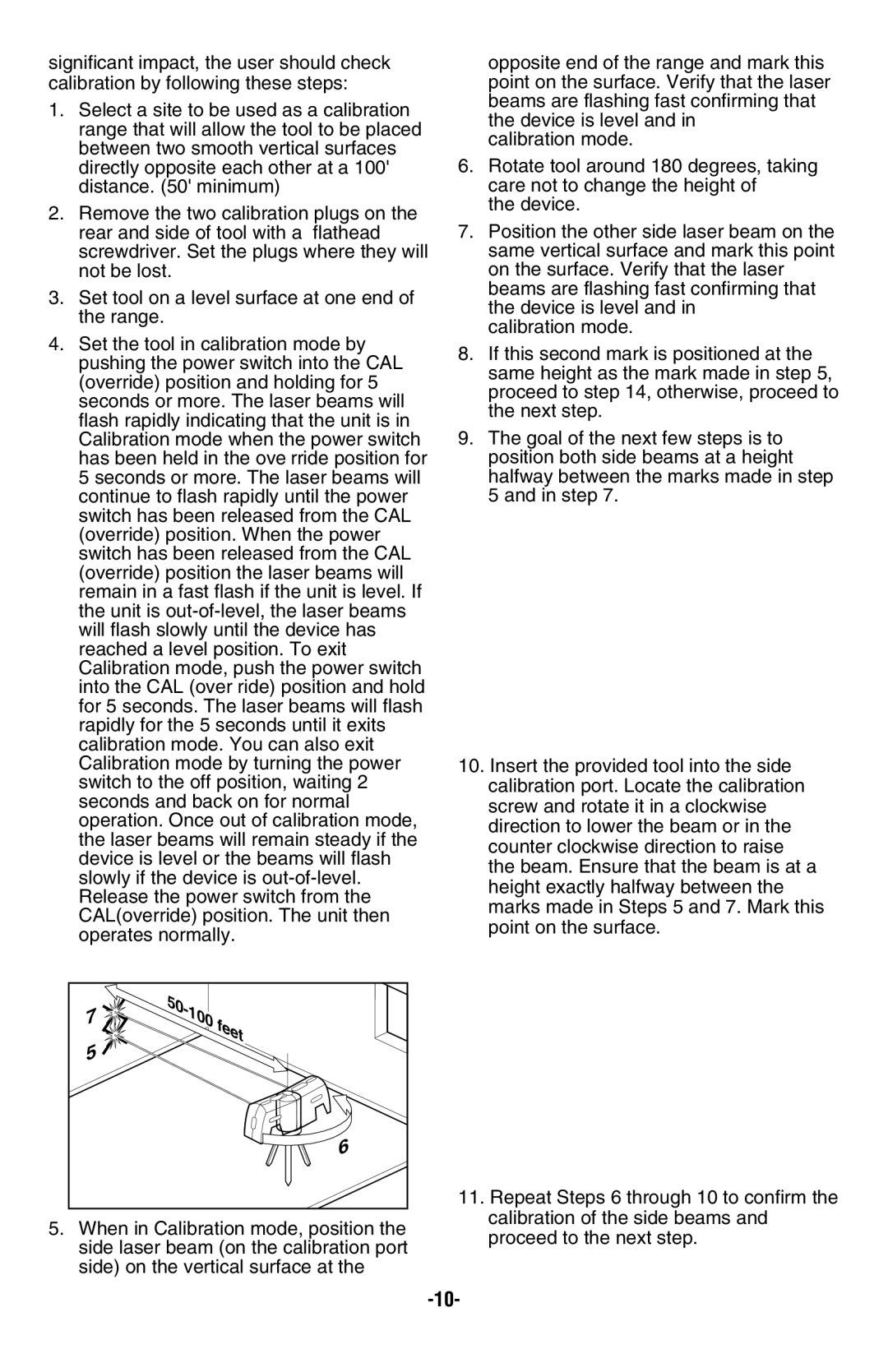

1.Select a site to be used as a calibration range that will allow the tool to be placed between two smooth vertical surfaces directly opposite each other at a 100' distance. (50' minimum)

2.Remove the two calibration plugs on the rear and side of tool with a flathead screwdriver. Set the plugs where they will not be lost.

3.Set tool on a level surface at one end of the range.

4.Set the tool in calibration mode by pushing the power switch into the CAL (override) position and holding for 5 seconds or more. The laser beams will flash rapidly indicating that the unit is in Calibration mode when the power switch has been held in the ove rride position for 5 seconds or more. The laser beams will continue to flash rapidly until the power switch has been released from the CAL (override) position. When the power switch has been released from the CAL (override) position the laser beams will remain in a fast flash if the unit is level. If the unit is

7 | - |

| |

5 |

|

| 6 |

5.When in Calibration mode, position the side laser beam (on the calibration port side) on the vertical surface at the

opposite end of the range and mark this point on the surface. Verify that the laser beams are flashing fast confirming that the device is level and in

calibration mode.

6.Rotate tool around 180 degrees, taking care not to change the height of

the device.

7.Position the other side laser beam on the same vertical surface and mark this point on the surface. Verify that the laser beams are flashing fast confirming that the device is level and in

calibration mode.

8.If this second mark is positioned at the same height as the mark made in step 5, proceed to step 14, otherwise, proceed to the next step.

9.The goal of the next few steps is to position both side beams at a height halfway between the marks made in step 5 and in step 7.

1 |

1/2 |

10 |

10.Insert the provided tool into the side calibration port. Locate the calibration screw and rotate it in a clockwise direction to lower the beam or in the counter clockwise direction to raise the beam. Ensure that the beam is at a height exactly halfway between the marks made in Steps 5 and 7. Mark this point on the surface.

11 |

11.Repeat Steps 6 through 10 to confirm the calibration of the side beams and proceed to the next step.