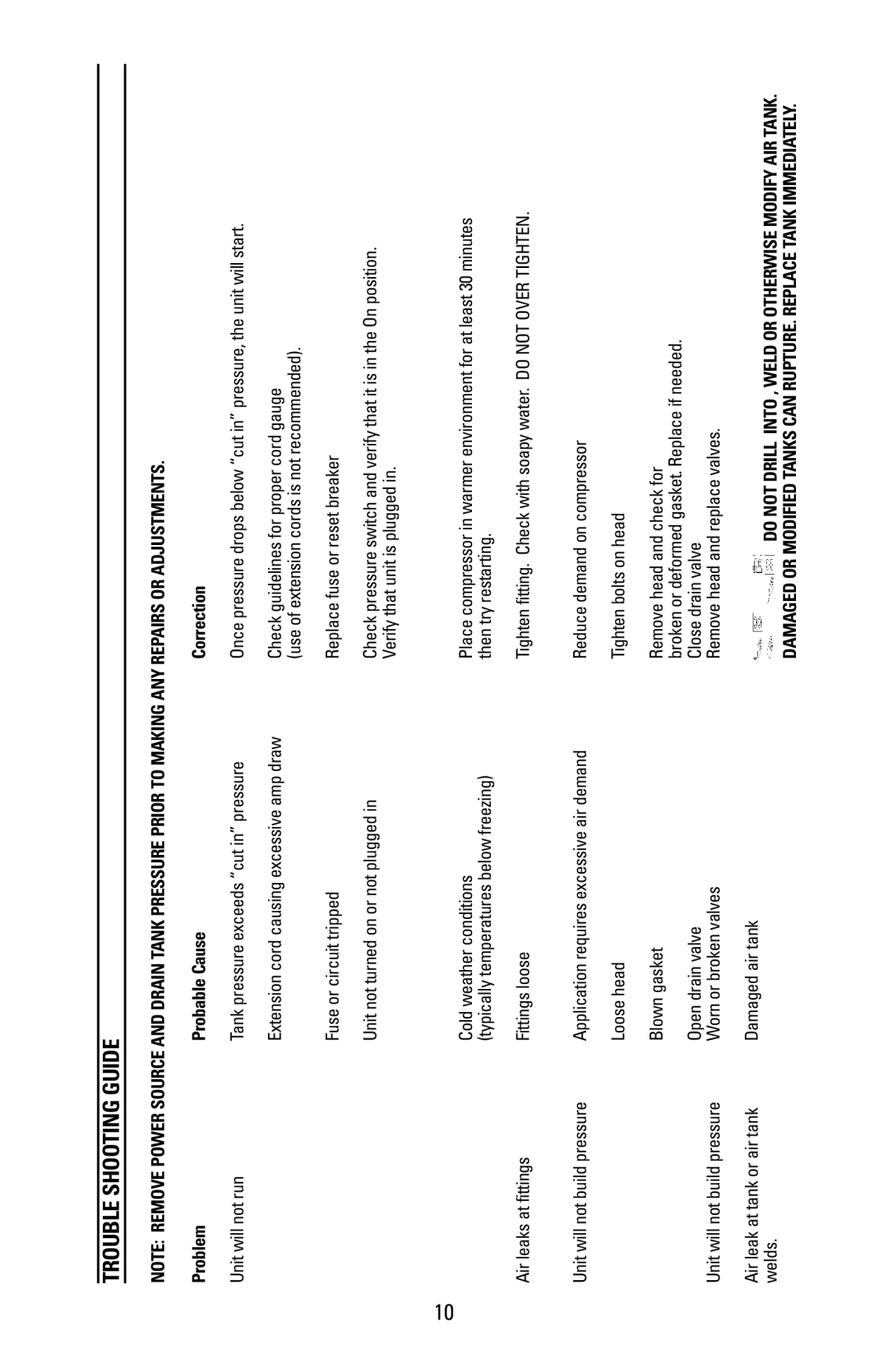

TROUBLE SHOOTING GUIDE

NOTE: REMOVE POWER SOURCE AND DRAIN TANK PRESSURE PRIOR TO MAKING ANY REPAIRS OR ADJUSTMENTS.

Problem | Probable Cause | Correction |

Unit will not run | Tank pressure exceeds “cut in” pressure | Once pressure drops below “cut in” pressure, the unit will start. |

| Extension cord causing excessive amp draw | Check guidelines for proper cord gauge |

|

| (use of extension cords is not recommended). |

| Fuse or circuit tripped | Replace fuse or reset breaker |

| Unit not turned on or not plugged in | Check pressure switch and verify that it is in the On position. |

|

| Verify that unit is plugged in. |

10 | Cold weather conditions | Place compressor in warmer environment for at least 30 minutes | ||

| ||||

| (typically temperatures below freezing) | then try restarting. | ||

Air leaks at fittings | Fittings loose | Tighten fitting. Check with soapy water. DO NOT OVER TIGHTEN. | ||

Unit will not build pressure | Application requires excessive air demand | Reduce demand on compressor | ||

| Loose head | Tighten bolts on head | ||

| Blown gasket | Remove head and check for | ||

|

| broken or deformed gasket. Replace if needed. | ||

| Open drain valve | Close drain valve | ||

Unit will not build pressure | Worn or broken valves | Remove head and replace valves. | ||

Air leak at tank or air tank | Damaged air tank |

|

|

|

welds. |

|

|

| DO NOT DRILL INTO , WELD OR OTHERWISE MODIFY AIR TANK. |

|

|

| ||

|

| DAMAGED OR MODIFIED TANKS CAN RUPTURE. REPLACE TANK IMMEDIATELY. | ||