Brute Mini Hydronic Boiler | Page 11 |

|

|

Distance |

|

| Boiler Size |

|

| ||

|

|

|

|

|

| ||

From Gas | 50 | 75 | 100 | 125 | 160 | 225 | |

Meter |

|

|

|

|

|

| |

|

| Pipe Size |

|

| |||

|

|

|

|

| |||

|

|

|

|

|

|

| |

1/2 | 3/4 | 3/4 | 3/4 | 1 | 1 | ||

|

|

|

|

|

| ||

3/4 | 3/4 | 3/4 | 1 | 1 | |||

|

|

|

|

|

| ||

3/4 | 1 | 1 | 1 | ||||

|

|

|

|

|

| ||

*Note: These figures are for Natural Gas (.65 Sp. Gr.), and are based on 1/2" water column pressure drop. Check supply pressure with a manometer, and local code requirements for variations. For LPG, reduce pipe diameter one size, but maintain a 1/2" minimum diameter. A 'normal' number of Tees and elbows have been taken into allowance.

Table 4. Natural Gas Pipe Size Requirements*

Gas Supply |

|

Inlet |

|

Tee | To Equipment |

Inlet | |

Fitting |

|

3 in. | Nipple |

(76mm) Min. |

|

| Cap |

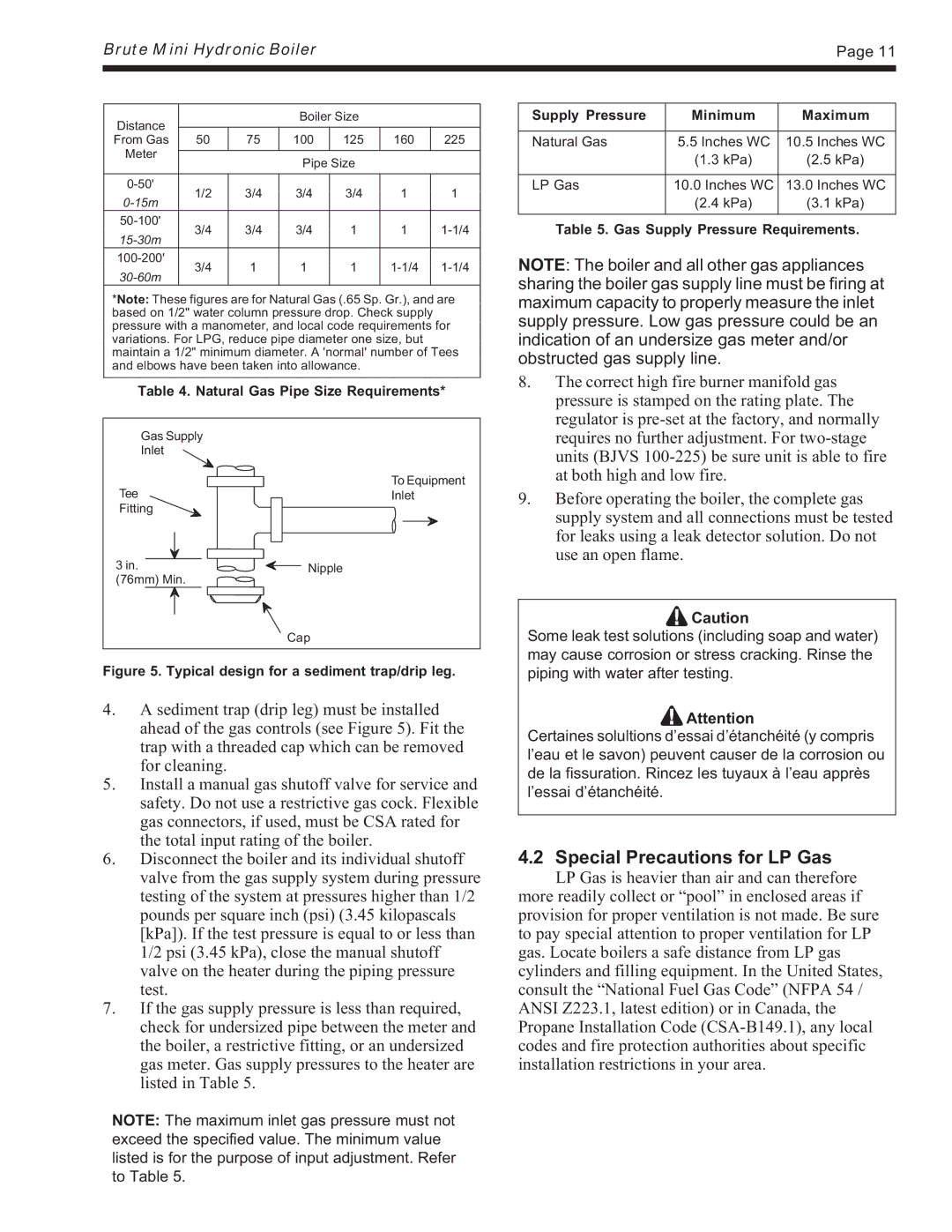

Figure 5. Typical design for a sediment trap/drip leg.

4.A sediment trap (drip leg) must be installed ahead of the gas controls (see Figure 5). Fit the trap with a threaded cap which can be removed for cleaning.

5.Install a manual gas shutoff valve for service and safety. Do not use a restrictive gas cock. Flexible gas connectors, if used, must be CSA rated for the total input rating of the boiler.

6.Disconnect the boiler and its individual shutoff valve from the gas supply system during pressure testing of the system at pressures higher than 1/2 pounds per square inch (psi) (3.45 kilopascals [kPa]). If the test pressure is equal to or less than 1/2 psi (3.45 kPa), close the manual shutoff valve on the heater during the piping pressure test.

7.If the gas supply pressure is less than required, check for undersized pipe between the meter and the boiler, a restrictive fitting, or an undersized gas meter. Gas supply pressures to the heater are listed in Table 5.

NOTE: The maximum inlet gas pressure must not exceed the specified value. The minimum value listed is for the purpose of input adjustment. Refer to Table 5.

Supply Pressure | Minimum | Maximum |

|

|

|

Natural Gas | 5.5 Inches WC | 10.5 Inches WC |

| (1.3 kPa) | (2.5 kPa) |

|

|

|

LP Gas | 10.0 Inches WC | 13.0 Inches WC |

| (2.4 kPa) | (3.1 kPa) |

Table 5. Gas Supply Pressure Requirements.

NOTE: The boiler and all other gas appliances sharing the boiler gas supply line must be firing at maximum capacity to properly measure the inlet supply pressure. Low gas pressure could be an indication of an undersize gas meter and/or obstructed gas supply line.

8.The correct high fire burner manifold gas pressure is stamped on the rating plate. The regulator is

9.Before operating the boiler, the complete gas supply system and all connections must be tested for leaks using a leak detector solution. Do not use an open flame.

![]() Caution

Caution

Some leak test solutions (including soap and water) may cause corrosion or stress cracking. Rinse the piping with water after testing.

![]() Attention

Attention

Certaines solultions d’essai d’étanchéité (y compris l’eau et le savon) peuvent causer de la corrosion ou de la fissuration. Rincez les tuyaux à l’eau apprès l’essai d’étanchéité.

4.2 Special Precautions for LP Gas

LP Gas is heavier than air and can therefore more readily collect or “pool” in enclosed areas if provision for proper ventilation is not made. Be sure to pay special attention to proper ventilation for LP gas. Locate boilers a safe distance from LP gas cylinders and filling equipment. In the United States, consult the “National Fuel Gas Code” (NFPA 54 / ANSI Z223.1, latest edition) or in Canada, the Propane Installation Code