Brute Mini Hydronic Boiler | Page 7 |

|

|

SECTION 3.

Venting

3.1 Combustion Air Supply

The boiler location must provide sufficient air supply for proper combustion, and ventilation of the surrounding area as outlined in the latest edition of ANSI standard Z223.1 or in Canada,

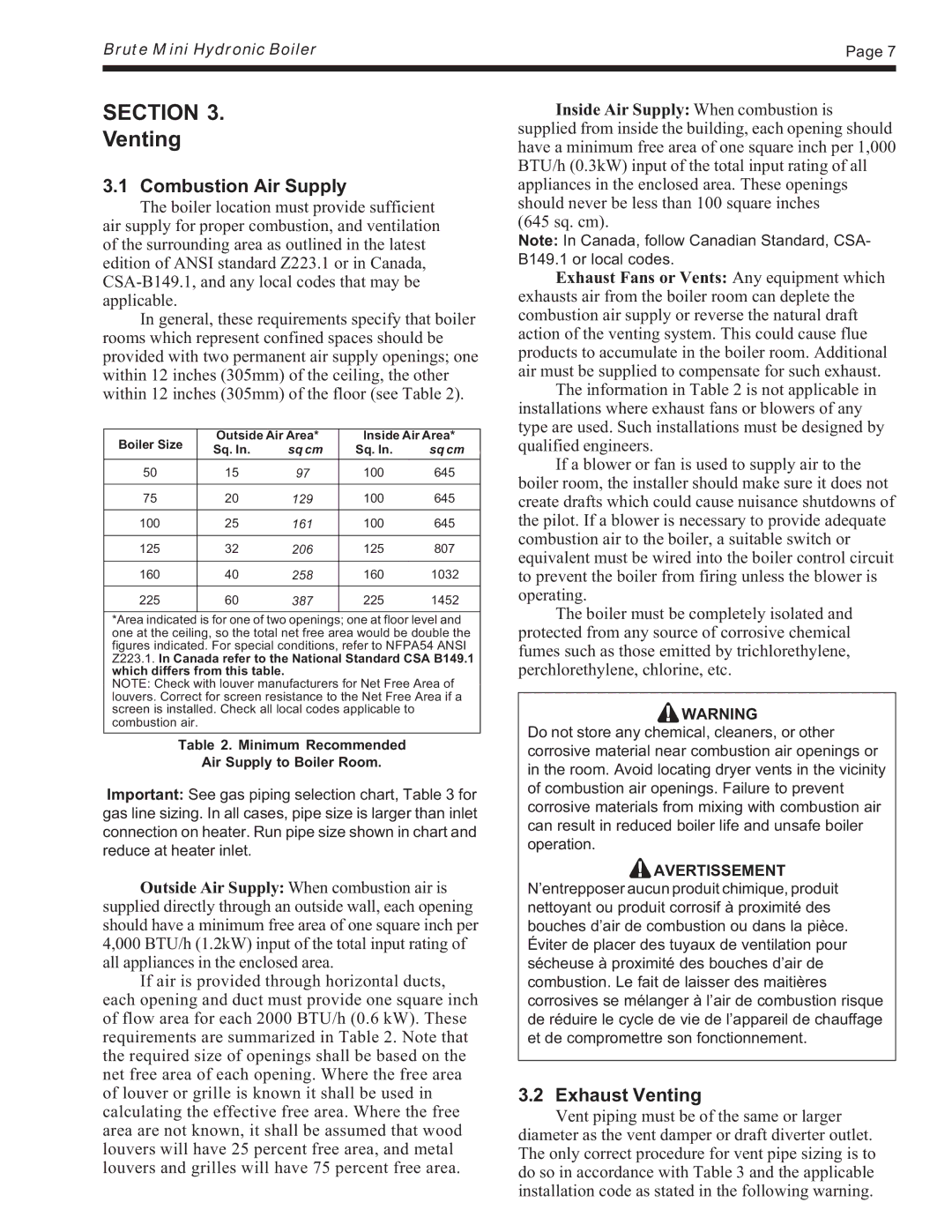

In general, these requirements specify that boiler rooms which represent confined spaces should be provided with two permanent air supply openings; one within 12 inches (305mm) of the ceiling, the other within 12 inches (305mm) of the floor (see Table 2).

Boiler Size | Outside Air Area* | Inside Air Area* | |||

Sq. In. | sq cm | Sq. In. | sq cm | ||

| |||||

50 | 15 | 97 | 100 | 645 | |

|

|

|

|

| |

75 | 20 | 129 | 100 | 645 | |

|

|

|

|

| |

100 | 25 | 161 | 100 | 645 | |

|

|

|

|

| |

125 | 32 | 206 | 125 | 807 | |

|

|

|

|

| |

160 | 40 | 258 | 160 | 1032 | |

|

|

|

|

| |

225 | 60 | 387 | 225 | 1452 | |

|

|

|

|

| |

*Area indicated is for one of two openings; one at floor level and one at the ceiling, so the total net free area would be double the figures indicated. For special conditions, refer to NFPA54 ANSI Z223.1. In Canada refer to the National Standard CSA B149.1 which differs from this table.

NOTE: Check with louver manufacturers for Net Free Area of louvers. Correct for screen resistance to the Net Free Area if a screen is installed. Check all local codes applicable to combustion air.

Table 2. Minimum Recommended

Air Supply to Boiler Room.

Important: See gas piping selection chart, Table 3 for gas line sizing. In all cases, pipe size is larger than inlet connection on heater. Run pipe size shown in chart and reduce at heater inlet.

Outside Air Supply: When combustion air is supplied directly through an outside wall, each opening should have a minimum free area of one square inch per 4,000 BTU/h (1.2kW) input of the total input rating of all appliances in the enclosed area.

If air is provided through horizontal ducts, each opening and duct must provide one square inch of flow area for each 2000 BTU/h (0.6 kW). These requirements are summarized in Table 2. Note that the required size of openings shall be based on the net free area of each opening. Where the free area of louver or grille is known it shall be used in calculating the effective free area. Where the free area are not known, it shall be assumed that wood louvers will have 25 percent free area, and metal louvers and grilles will have 75 percent free area.

Inside Air Supply: When combustion is supplied from inside the building, each opening should have a minimum free area of one square inch per 1,000 BTU/h (0.3kW) input of the total input rating of all appliances in the enclosed area. These openings should never be less than 100 square inches

(645 sq. cm).

Note: In Canada, follow Canadian Standard, CSA- B149.1 or local codes.

Exhaust Fans or Vents: Any equipment which exhausts air from the boiler room can deplete the combustion air supply or reverse the natural draft action of the venting system. This could cause flue products to accumulate in the boiler room. Additional air must be supplied to compensate for such exhaust.

The information in Table 2 is not applicable in installations where exhaust fans or blowers of any type are used. Such installations must be designed by qualified engineers.

If a blower or fan is used to supply air to the boiler room, the installer should make sure it does not create drafts which could cause nuisance shutdowns of the pilot. If a blower is necessary to provide adequate combustion air to the boiler, a suitable switch or equivalent must be wired into the boiler control circuit to prevent the boiler from firing unless the blower is operating.

The boiler must be completely isolated and protected from any source of corrosive chemical fumes such as those emitted by trichlorethylene, perchlorethylene, chlorine, etc.

![]() WARNING

WARNING

Do not store any chemical, cleaners, or other corrosive material near combustion air openings or in the room. Avoid locating dryer vents in the vicinity of combustion air openings. Failure to prevent corrosive materials from mixing with combustion air can result in reduced boiler life and unsafe boiler operation.

AVERTISSEMENT

AVERTISSEMENT

N’entrepposer aucun produit chimique, produit nettoyant ou produit corrosif à proximité des bouches d’air de combustion ou dans la pièce. Éviter de placer des tuyaux de ventilation pour sécheuse à proximité des bouches d’air de combustion. Le fait de laisser des maitières corrosives se mélanger à l’air de combustion risque de réduire le cycle de vie de l’appareil de chauffage et de compromettre son fonctionnement.

3.2 Exhaust Venting

Vent piping must be of the same or larger diameter as the vent damper or draft diverter outlet. The only correct procedure for vent pipe sizing is to do so in accordance with Table 3 and the applicable installation code as stated in the following warning.