Page 8 | BRADFORD WHITE CORP. |

|

|

![]() WARNING

WARNING

Vent pipe diameter must be as required by the National fuel Gas Code Z223.1 or the Canadian Installation Codes for Gas Appliances

AVERTISSEMENT

AVERTISSEMENT

Le diamètre des tuyaux de ventilation doit répondre aux exigences du National Fuel Gas Code Z223.1 ou du code canadien des installations des appareils

àgaz CSA B149.1. Des tuyaux trop petits rispquent d’entraîner une ventilation inadéquate et des tuyaux trop gros risquent de provoquer une condensation dans les tuyaux. Dans un cas comme dans l’autre, des produits de combustion risquent de s’échapper dans le bâtiment et causer des blessures graves ou l’asphyxie par le monoxyde de carbone.

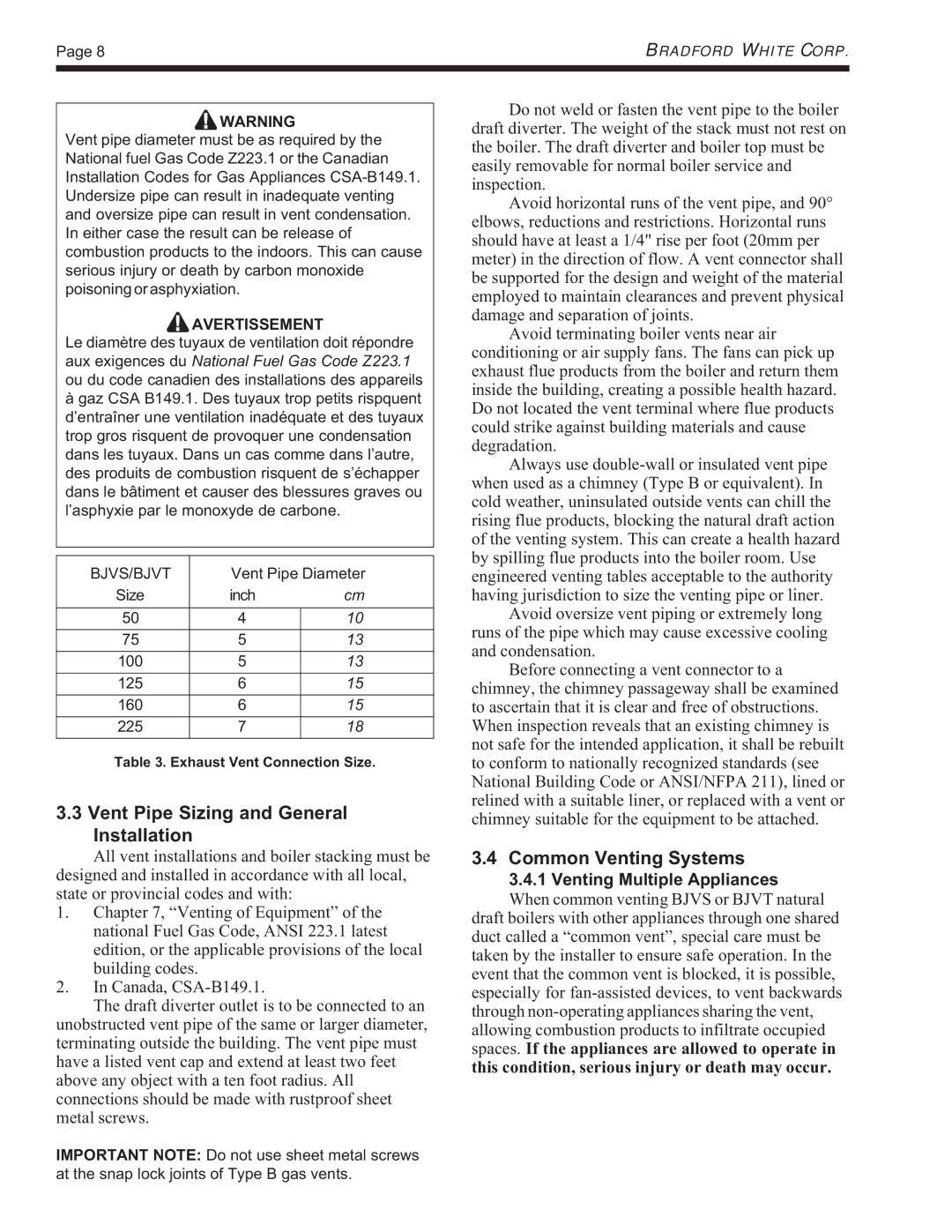

BJVS/BJVT | Vent Pipe Diameter | |

Size | inch | cm |

|

|

|

50 | 4 | 10 |

75 | 5 | 13 |

100 | 5 | 13 |

125 | 6 | 15 |

160 | 6 | 15 |

225 | 7 | 18 |

Table 3. Exhaust Vent Connection Size.

3.3Vent Pipe Sizing and General Installation

All vent installations and boiler stacking must be designed and installed in accordance with all local, state or provincial codes and with:

1.Chapter 7, “Venting of Equipment” of the national Fuel Gas Code, ANSI 223.1 latest edition, or the applicable provisions of the local building codes.

2.In Canada,

The draft diverter outlet is to be connected to an

unobstructed vent pipe of the same or larger diameter, terminating outside the building. The vent pipe must have a listed vent cap and extend at least two feet above any object with a ten foot radius. All connections should be made with rustproof sheet metal screws.

Do not weld or fasten the vent pipe to the boiler draft diverter. The weight of the stack must not rest on the boiler. The draft diverter and boiler top must be easily removable for normal boiler service and inspection.

Avoid horizontal runs of the vent pipe, and 90° elbows, reductions and restrictions. Horizontal runs should have at least a 1/4" rise per foot (20mm per meter) in the direction of flow. A vent connector shall be supported for the design and weight of the material employed to maintain clearances and prevent physical damage and separation of joints.

Avoid terminating boiler vents near air conditioning or air supply fans. The fans can pick up exhaust flue products from the boiler and return them inside the building, creating a possible health hazard. Do not located the vent terminal where flue products could strike against building materials and cause degradation.

Always use

Avoid oversize vent piping or extremely long runs of the pipe which may cause excessive cooling and condensation.

Before connecting a vent connector to a chimney, the chimney passageway shall be examined to ascertain that it is clear and free of obstructions. When inspection reveals that an existing chimney is not safe for the intended application, it shall be rebuilt to conform to nationally recognized standards (see National Building Code or ANSI/NFPA 211), lined or relined with a suitable liner, or replaced with a vent or chimney suitable for the equipment to be attached.

3.4Common Venting Systems

3.4.1 Venting Multiple Appliances

When common venting BJVS or BJVT natural draft boilers with other appliances through one shared duct called a “common vent”, special care must be taken by the installer to ensure safe operation. In the event that the common vent is blocked, it is possible, especially for

IMPORTANT NOTE: Do not use sheet metal screws at the snap lock joints of Type B gas vents.