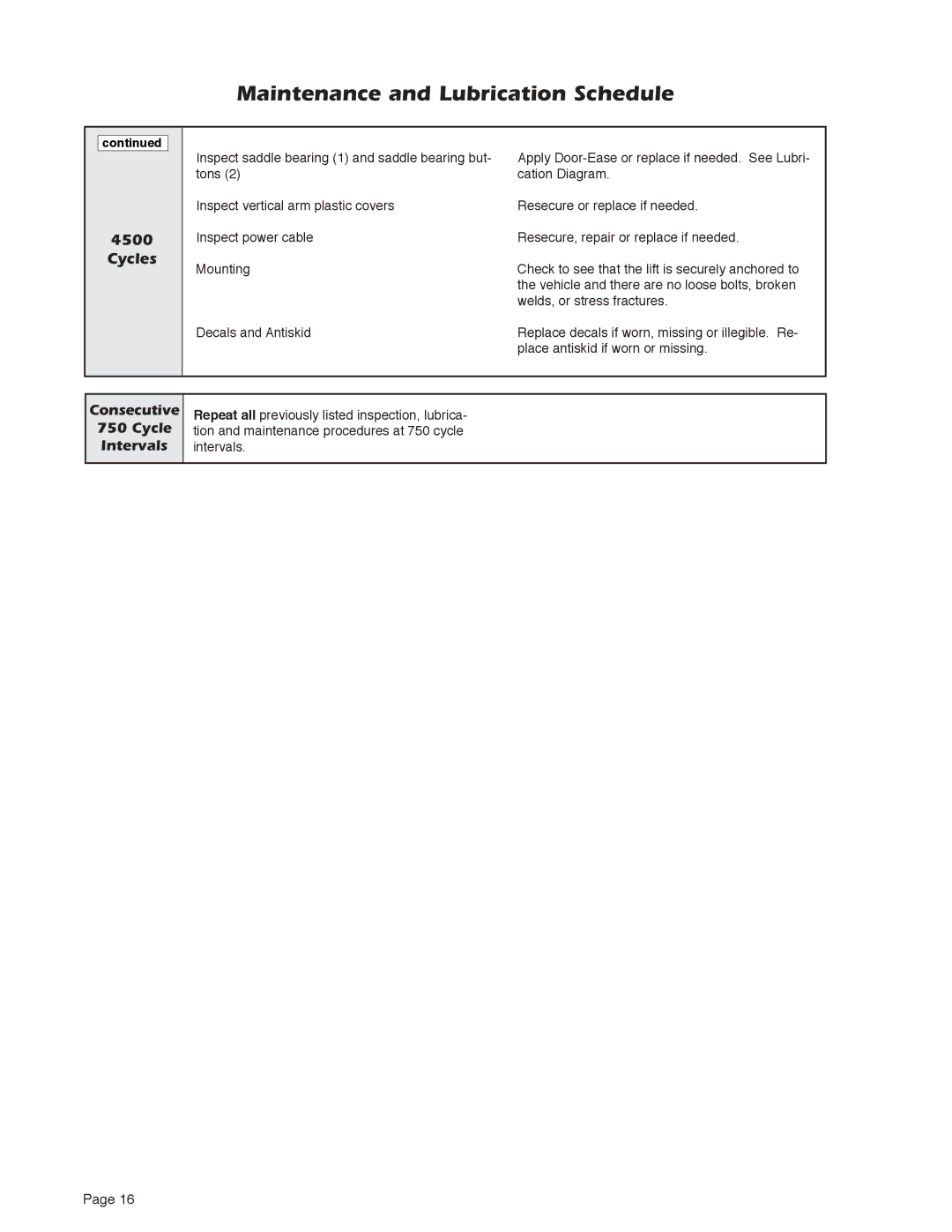

Maintenance and Lubrication Schedule

|

|

|

|

|

| continued |

|

|

|

|

|

| Inspect saddle bearing (1) and saddle bearing but- | Apply |

|

|

| tons (2) | cation Diagram. |

|

|

| Inspect vertical arm plastic covers | Resecure or replace if needed. |

4500 |

| Inspect power cable | Resecure, repair or replace if needed. | |

| Cycles | Mounting | Check to see that the lift is securely anchored to | |

|

|

| ||

|

|

|

| the vehicle and there are no loose bolts, broken |

|

|

|

| welds, or stress fractures. |

|

|

| Decals and Antiskid | Replace decals if worn, missing or illegible. Re- |

|

|

|

| place antiskid if worn or missing. |

|

|

|

|

|

Consecutive

750Cycle Intervals

Repeat all previously listed inspection, lubrica- tion and maintenance procedures at 750 cycle intervals.

Page 16