TROUBLESHOOTING

Before You Call

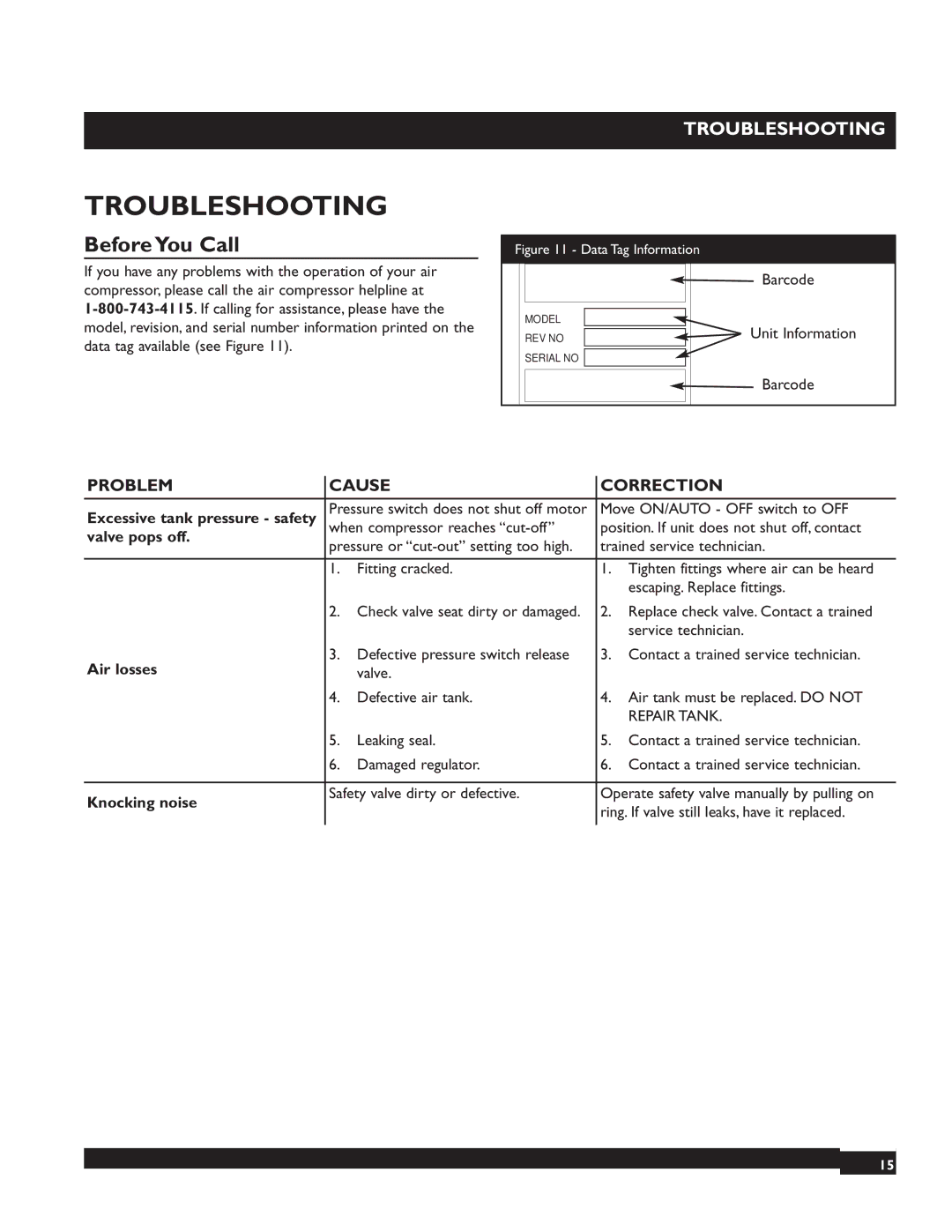

If you have any problems with the operation of your air compressor, please call the air compressor helpline at

TROUBLESHOOTING

Figure 11 - Data Tag Information

|

|

|

|

|

|

|

|

|

| Barcode |

|

|

|

|

|

|

|

MODEL |

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

| |

REV NO |

|

|

| Unit Information | |

| |||||

SERIAL NO

Barcode

PROBLEM | CAUSE | CORRECTION | |||

Excessive tank pressure - safety | Pressure switch does not shut off motor | Move ON/AUTO - OFF switch to OFF | |||

valve pops off. | when compressor reaches | position. If unit does not shut off, contact | |||

pressure or | trained service technician. | ||||

| |||||

|

|

|

|

| |

| 1. | Fitting cracked. | 1. | Tighten fittings where air can be heard | |

|

|

|

| escaping. Replace fittings. | |

| 2. | Check valve seat dirty or damaged. | 2. | Replace check valve. Contact a trained | |

|

|

|

| service technician. | |

Air losses | 3. | Defective pressure switch release | 3. | Contact a trained service technician. | |

| valve. |

|

| ||

| 4. | Defective air tank. | 4. | Air tank must be replaced. DO NOT | |

|

|

|

| REPAIR TANK. | |

| 5. | Leaking seal. | 5. | Contact a trained service technician. | |

| 6. | Damaged regulator. | 6. | Contact a trained service technician. | |

|

|

| |||

Knocking noise | Safety valve dirty or defective. | Operate safety valve manually by pulling on | |||

|

| ring. If valve still leaks, have it replaced. | |||

|

|

| |||

|

|

|

|

| |

15