SPECIFICATIONS / MAINTENANCE

PRODUCT SPECIFICATIONS

AC Frequency: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60Hz

Rated AC Voltage: . . . . . . . . . . . . . . . . . 120 volts, single phase

Running Horsepower: . . . . . . . . . . . . . . . . . . . . . . . . . . 1.5 HP

Pump Type: . . . . . . . . . . . . . . . . . . Oil Lubricated Direct Drive

Lubricant:. . . . . . . . . . . . . . . . . . . . . . . . . SAE 5W50 Synthetic

Oil Capacity: . . . . . . . . . . . . . . . . . . . . . . . . . 7.168 oz. (200ml) Air Delivery:

at 40 psi:. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5.1 CFM

at 90 psi:. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.0 CFM

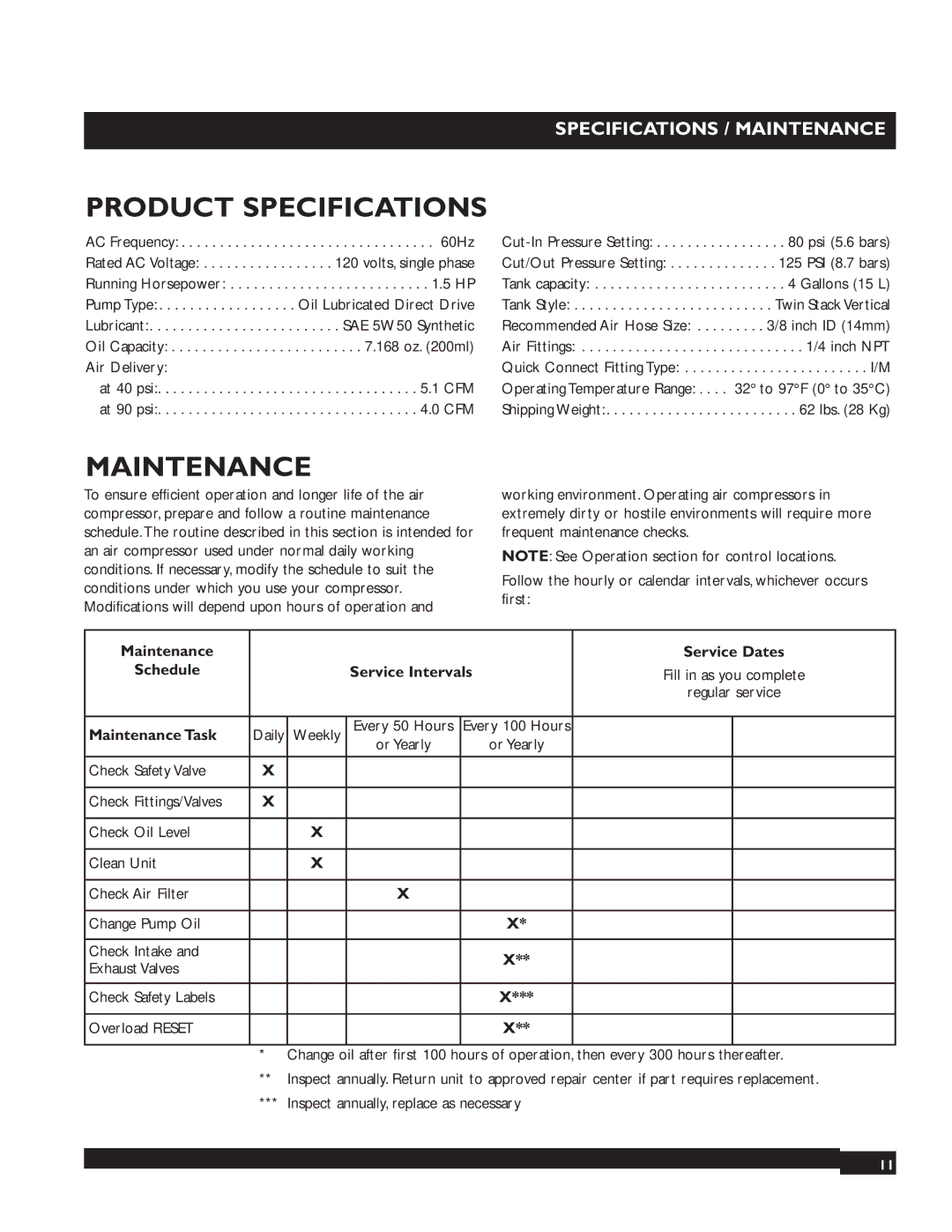

MAINTENANCE

To ensure efficient operation and longer life of the air compressor, prepare and follow a routine maintenance schedule.The routine described in this section is intended for an air compressor used under normal daily working conditions. If necessary, modify the schedule to suit the conditions under which you use your compressor. Modifications will depend upon hours of operation and

Cut/Out Pressure Setting: . . . . . . . . . . . . . . 125 PSI (8.7 bars)

Tank capacity: . . . . . . . . . . . . . . . . . . . . . . . . . 4 Gallons (15 L)

Tank Style: . . . . . . . . . . . . . . . . . . . . . . . . . . Twin Stack Vertical

Recommended Air Hose Size: . . . . . . . . . 3/8 inch ID (14mm)

Air Fittings: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1/4 inch NPT

Quick Connect Fitting Type: . . . . . . . . . . . . . . . . . . . . . . . . I/M

Operating Temperature Range: . . . . 32° to 97°F (0° to 35°C)

Shipping Weight:. . . . . . . . . . . . . . . . . . . . . . . . . 62 lbs. (28 Kg)

working environment. Operating air compressors in extremely dirty or hostile environments will require more frequent maintenance checks.

NOTE: See Operation section for control locations.

Follow the hourly or calendar intervals, whichever occurs first:

Maintenance |

|

|

|

|

| Service Dates | |

Schedule |

|

| Service Intervals |

| Fill in as you complete | ||

|

|

|

|

|

| regular service | |

|

|

|

|

|

| ||

Maintenance Task | Daily | Weekly | Every 50 Hours | Every 100 Hours |

|

| |

|

|

| or Yearly |

| or Yearly |

|

|

Check Safety Valve | X |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Check Fittings/Valves | X |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Check Oil Level |

| X |

|

|

|

|

|

|

|

|

|

|

|

|

|

Clean Unit |

| X |

|

|

|

|

|

|

|

|

|

|

|

|

|

Check Air Filter |

|

| X |

|

|

|

|

|

|

|

|

|

|

|

|

Change Pump Oil |

|

|

|

| X* |

|

|

|

|

|

|

|

|

|

|

Check Intake and |

|

|

|

| X** |

|

|

Exhaust Valves |

|

|

|

|

|

| |

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

Check Safety Labels |

|

|

|

| X*** |

|

|

|

|

|

|

|

|

|

|

Overload RESET |

|

|

|

| X** |

|

|

|

|

|

|

|

|

|

|

*Change oil after first 100 hours of operation, then every 300 hours thereafter.

**Inspect annually. Return unit to approved repair center if part requires replacement.

***Inspect annually, replace as necessary

11