XIII. BASE UNIT OPERATION

A. Cooling, Units Without Economizer

When thermostat calls for cooling, terminals G and Y1 are energized. The indoor (evaporator) fan contactor (IFC), and compressor contactor no. 1 (C1) are energized and evaporator- fan motor, compressor no. 1 and condenser fans start. The condenser-fan motors run continuously while unit is cooling. If the thermostat calls for a second stage of cooling by ener- gizing Y2, compressor contactor no. 2 (C2) is energized and compressor no. 2 starts.

B.Heating, Units Without Economizer (If Accessory or Op- tional Heater is Installed)

Upon a call for heating through terminal W1, IFC and heater contactor no. 1 (HC1) are energized. On units equipped for 2 stages of heat, when additional heat is needed, HC2 is en- ergized through W2.

C. Cooling, Units With Economizer

Upon a call for cooling, when outdoor ambient temperature is above the outdoor-air temperature control setting, the evapo- rator and condenser fans and compressor energize. The econo- mizer damper moves to VENT position.

Upon a ®rst-stage call for cooling, when outdoor ambient temperature is below the temperature control setting, the evapo- rator fan starts and economizer damper modulates to main- tain mixed-air temperature. The compressor(s) remains off.

Upon a second-stage call for cooling, compressor no. 1 is en- ergized and mechanical cooling is integrated with econo- mizer cooling. Compressor no. 2 is locked out. If the outdoor- air temperature is below 50 F, a cooling lockout switch prevents the compressor(s) from running.

When supply-air temperature drops below a ®xed set point, the economizer damper modulates to maintain the tempera- ture at the ®xed set point.

D. Freeze Protection Thermostat

A freeze protection thermostat (FPT) is located on the evapo- rator coil. It detects frost build-up and turns off the compres- sor, allowing the coil to clear. Once frost has melted, the com- pressor can be reenergized by resetting the compressor lockout.

E.Heating, Units With Economizer (If Accessory or Op- tional Heater Is Installed)

The outdoor air damper stays at VENT position while the evapo- rator fan is operating. Upon a call for heating through ter- minal W1, the indoor (evaporator) fan contactor (IFC) and heater contactor no. 1 (HC1) are energized. On units equipped for 2 stages of heat, when additional heat is needed, HC2 is energized through W2.

SERVICE

WARNING: Before performing service or mainte- nance operations on unit, turn off main power switch to unit. Turn off accessory heater power switch if appli- cable. Electrical shock could cause personal injury.

WARNING: Before performing service or mainte- nance operations on unit, turn off main power switch to unit. Turn off accessory heater power switch if appli- cable. Electrical shock could cause personal injury.

I. CLEANING

Inspect unit interior at beginning of each heating and cool- ing season and as operating conditions require. Remove unit top panel and/or side panels for access to unit interior.

A. Evaporator Coil

Clean as required with a commercial coil cleaner.

NOTE: The 559F300 unit has a mist eliminator screen attached to the evaporator coil to prevent condensate runoff at high wet-bulb conditions. Check periodically and clean as necessary.

B. Condenser Coil

Clean condenser coil annually and as required by location and outdoor-air conditions. Inspect coil monthly Ð clean as required.

C. Condensate Drain

Check and clean each year at start of cooling season.

D. Filters

Clean or replace at start of each heating and cooling season, or more often if operating conditions require. Refer to Table 1 for type and size.

NOTE: The 559F300 unit requires industrial grade throw- away ®lters capable of withstanding face velocities up to 625 fpm. Ensure that replacement ®lters for the 559F300 units are rated for 625 fpm.

E. Outdoor-Air Inlet Screens

Clean screens with steam or hot water and a mild detergent. Do not use throwaway ®lters in place of screens.

II. LUBRICATION

A. Compressors

Each compressor is charged with the correct amount of oil at the factory. Conventional white oil (Sontext 200LT) is used. White oil is compatible with 3GS oil, and 3GS oil may be used if the addition of oil is required. See compressor nameplate for original oil charge. A complete recharge should be four ounces less than the original oil charge. When a com- pressor is exchanged in the ®eld it is possible that a major portion of the oil from the replaced compressor may still be in the system. While this will not affect the reliability of the replacement compressor, the extra oil will add rotor drag and increase power usage. To remove this excess oil, an access valve may be added to the lower portion of the suction line at the inlet of the compressor. The compressor should then be run for 10 minutes, shut down, and the access valve opened until no oil ¯ows. This should be repeated twice to make sure the proper oil level has been achieved.

B. Fan Shaft Bearings

For size 180 units, bearings are permanently lubricated. No ®eld lubrication is required. For size 216-300 units, the bear- ings are of the pillow block type and have grease ®ttings. The bearing opposite the motor end has an extended tube line so it can be lubricated from the motor side. Lubricate the bear- ings twice annually.

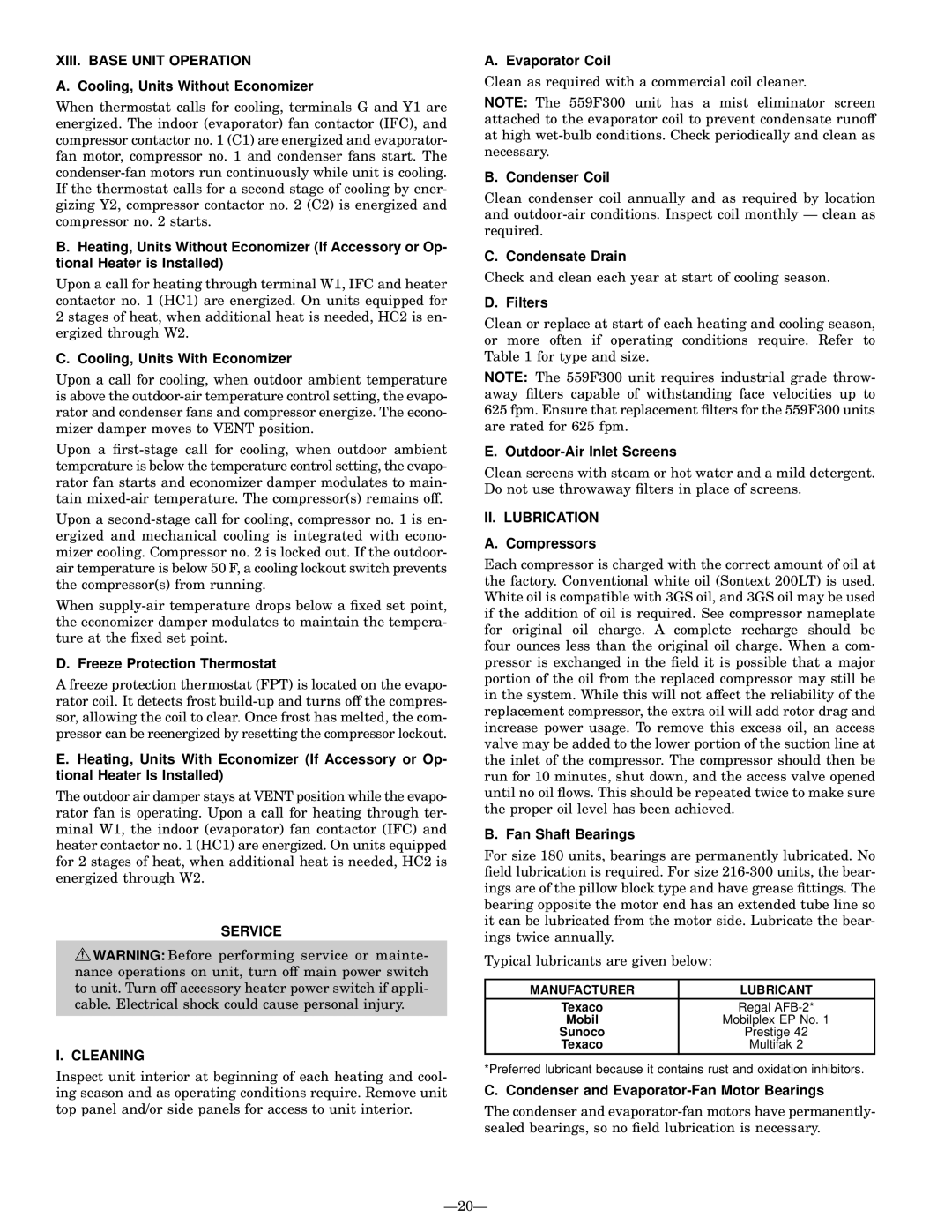

Typical lubricants are given below:

MANUFACTURER | LUBRICANT |

Texaco | Regal AFB-2* |

Mobil | Mobilplex EP No. 1 |

Sunoco | Prestige 42 |

Texaco | Multifak 2 |

*Preferred lubricant because it contains rust and oxidation inhibitors.

C. Condenser and Evaporator-Fan Motor Bearings

The condenser and evaporator-fan motors have permanently- sealed bearings, so no ®eld lubrication is necessary.