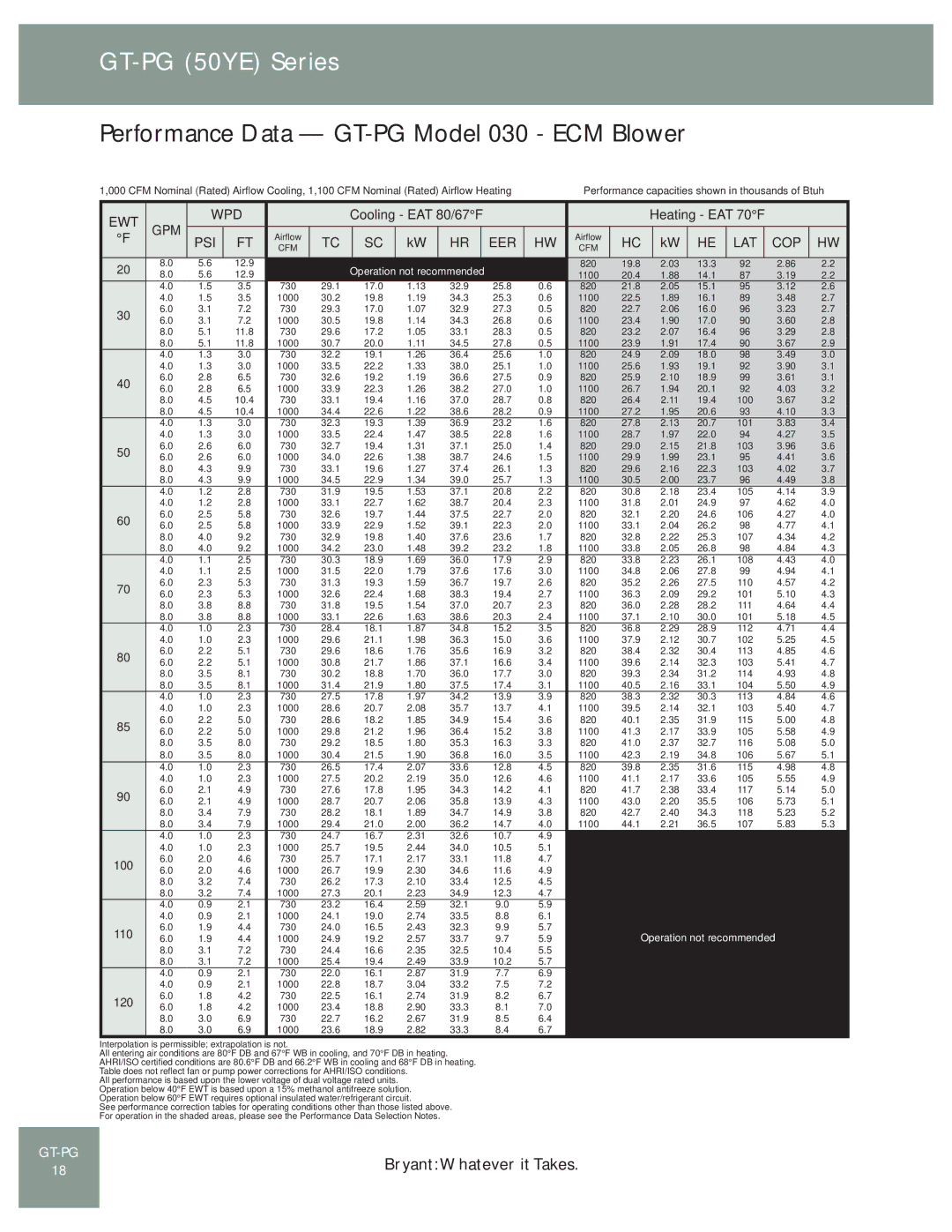

GT-PG (50YE) Series

Performance Data — GT-PG Model 030 - ECM Blower

1,000 CFM Nominal (Rated) Airflow Cooling, 1,100 CFM Nominal (Rated) Airflow HeatingPerformance capacities shown in thousands of Btuh

EWT | | WPD | | | Cooling - EAT 80/67°F | | | | | Heating - EAT 70°F | | | |

GPM | | | Airflow | | | | | | | | Airflow | | | | | | | | |

°F | | PSI | FT | TC | SC | kW | HR | | EER | HW | HC | kW | HE | LAT | | COP | HW |

| | CFM | | CFM | |

| | | | | | | | | | | | | | | | | | |

20 | 8.0 | 5.6 | 12.9 | N/A | N/A | N/A | N/A | N/A | | N/A | N/A | 820 | 19.8 | 2.03 | 13.3 | 92 | | | 2.86 | 2.2 |

8.0 | 5.6 | 12.9 | N/A | N/A | OperationN/A | notN/ArecommendedN/A | | N/A | N/A | 1100 | 20.4 | 1.88 | 14.1 | 87 | | | 3.19 | 2.2 |

| 4.0 | 1.5 | 3.5 | 730 | 29.1 | 17.0 | 1.13 | 32.9 | | 25.8 | 0.6 | 820 | 21.8 | 2.05 | 15.1 | 95 | | | 3.12 | 2.6 |

| 4.0 | 1.5 | 3.5 | 1000 | 30.2 | 19.8 | 1.19 | 34.3 | | 25.3 | 0.6 | 1100 | 22.5 | 1.89 | 16.1 | 89 | | | 3.48 | 2.7 |

30 | 6.0 | 3.1 | 7.2 | 730 | 29.3 | 17.0 | 1.07 | 32.9 | | 27.3 | 0.5 | 820 | 22.7 | 2.06 | 16.0 | 96 | | | 3.23 | 2.7 |

6.0 | 3.1 | 7.2 | 1000 | 30.5 | 19.8 | 1.14 | 34.3 | | 26.8 | 0.6 | 1100 | 23.4 | 1.90 | 17.0 | 90 | | | 3.60 | 2.8 |

| | | |

| 8.0 | 5.1 | 11.8 | 730 | 29.6 | 17.2 | 1.05 | 33.1 | | 28.3 | 0.5 | 820 | 23.2 | 2.07 | 16.4 | 96 | | | 3.29 | 2.8 |

| 8.0 | 5.1 | 11.8 | 1000 | 30.7 | 20.0 | 1.11 | 34.5 | | 27.8 | 0.5 | 1100 | 23.9 | 1.91 | 17.4 | 90 | | | 3.67 | 2.9 |

| 4.0 | 1.3 | 3.0 | 730 | 32.2 | 19.1 | 1.26 | 36.4 | | 25.6 | 1.0 | 820 | 24.9 | 2.09 | 18.0 | 98 | | | 3.49 | 3.0 |

| 4.0 | 1.3 | 3.0 | 1000 | 33.5 | 22.2 | 1.33 | 38.0 | | 25.1 | 1.0 | 1100 | 25.6 | 1.93 | 19.1 | 92 | | | 3.90 | 3.1 |

40 | 6.0 | 2.8 | 6.5 | 730 | 32.6 | 19.2 | 1.19 | 36.6 | | 27.5 | 0.9 | 820 | 25.9 | 2.10 | 18.9 | 99 | | | 3.61 | 3.1 |

6.0 | 2.8 | 6.5 | 1000 | 33.9 | 22.3 | 1.26 | 38.2 | | 27.0 | 1.0 | 1100 | 26.7 | 1.94 | 20.1 | 92 | | | 4.03 | 3.2 |

| | | |

| 8.0 | 4.5 | 10.4 | 730 | 33.1 | 19.4 | 1.16 | 37.0 | | 28.7 | 0.8 | 820 | 26.4 | 2.11 | 19.4 | 100 | | | 3.67 | 3.2 |

| 8.0 | 4.5 | 10.4 | 1000 | 34.4 | 22.6 | 1.22 | 38.6 | | 28.2 | 0.9 | 1100 | 27.2 | 1.95 | 20.6 | 93 | | | 4.10 | 3.3 |

| 4.0 | 1.3 | 3.0 | 730 | 32.3 | 19.3 | 1.39 | 36.9 | | 23.2 | 1.6 | 820 | 27.8 | 2.13 | 20.7 | 101 | | | 3.83 | 3.4 |

| 4.0 | 1.3 | 3.0 | 1000 | 33.5 | 22.4 | 1.47 | 38.5 | | 22.8 | 1.6 | 1100 | 28.7 | 1.97 | 22.0 | 94 | | | 4.27 | 3.5 |

50 | 6.0 | 2.6 | 6.0 | 730 | 32.7 | 19.4 | 1.31 | 37.1 | | 25.0 | 1.4 | 820 | 29.0 | 2.15 | 21.8 | 103 | | | 3.96 | 3.6 |

6.0 | 2.6 | 6.0 | 1000 | 34.0 | 22.6 | 1.38 | 38.7 | | 24.6 | 1.5 | 1100 | 29.9 | 1.99 | 23.1 | 95 | | | 4.41 | 3.6 |

| | | |

| 8.0 | 4.3 | 9.9 | 730 | 33.1 | 19.6 | 1.27 | 37.4 | | 26.1 | 1.3 | 820 | 29.6 | 2.16 | 22.3 | 103 | | | 4.02 | 3.7 |

| 8.0 | 4.3 | 9.9 | 1000 | 34.5 | 22.9 | 1.34 | 39.0 | | 25.7 | 1.3 | 1100 | 30.5 | 2.00 | 23.7 | 96 | | | 4.49 | 3.8 |

| 4.0 | 1.2 | 2.8 | 730 | 31.9 | 19.5 | 1.53 | 37.1 | | 20.8 | 2.2 | 820 | 30.8 | 2.18 | 23.4 | 105 | | | 4.14 | 3.9 |

| 4.0 | 1.2 | 2.8 | 1000 | 33.1 | 22.7 | 1.62 | 38.7 | | 20.4 | 2.3 | 1100 | 31.8 | 2.01 | 24.9 | 97 | | | 4.62 | 4.0 |

60 | 6.0 | 2.5 | 5.8 | 730 | 32.6 | 19.7 | 1.44 | 37.5 | | 22.7 | 2.0 | 820 | 32.1 | 2.20 | 24.6 | 106 | | | 4.27 | 4.0 |

6.0 | 2.5 | 5.8 | 1000 | 33.9 | 22.9 | 1.52 | 39.1 | | 22.3 | 2.0 | 1100 | 33.1 | 2.04 | 26.2 | 98 | | | 4.77 | 4.1 |

| | | |

| 8.0 | 4.0 | 9.2 | 730 | 32.9 | 19.8 | 1.40 | 37.6 | | 23.6 | 1.7 | 820 | 32.8 | 2.22 | 25.3 | 107 | | | 4.34 | 4.2 |

| 8.0 | 4.0 | 9.2 | 1000 | 34.2 | 23.0 | 1.48 | 39.2 | | 23.2 | 1.8 | 1100 | 33.8 | 2.05 | 26.8 | 98 | | | 4.84 | 4.3 |

| 4.0 | 1.1 | 2.5 | 730 | 30.3 | 18.9 | 1.69 | 36.0 | | 17.9 | 2.9 | 820 | 33.8 | 2.23 | 26.1 | 108 | | | 4.43 | 4.0 |

| 4.0 | 1.1 | 2.5 | 1000 | 31.5 | 22.0 | 1.79 | 37.6 | | 17.6 | 3.0 | 1100 | 34.8 | 2.06 | 27.8 | 99 | | | 4.94 | 4.1 |

70 | 6.0 | 2.3 | 5.3 | 730 | 31.3 | 19.3 | 1.59 | 36.7 | | 19.7 | 2.6 | 820 | 35.2 | 2.26 | 27.5 | 110 | | | 4.57 | 4.2 |

6.0 | 2.3 | 5.3 | 1000 | 32.6 | 22.4 | 1.68 | 38.3 | | 19.4 | 2.7 | 1100 | 36.3 | 2.09 | 29.2 | 101 | | | 5.10 | 4.3 |

| | | |

| 8.0 | 3.8 | 8.8 | 730 | 31.8 | 19.5 | 1.54 | 37.0 | | 20.7 | 2.3 | 820 | 36.0 | 2.28 | 28.2 | 111 | | | 4.64 | 4.4 |

| 8.0 | 3.8 | 8.8 | 1000 | 33.1 | 22.6 | 1.63 | 38.6 | | 20.3 | 2.4 | 1100 | 37.1 | 2.10 | 30.0 | 101 | | | 5.18 | 4.5 |

| 4.0 | 1.0 | 2.3 | 730 | 28.4 | 18.1 | 1.87 | 34.8 | | 15.2 | 3.5 | 820 | 36.8 | 2.29 | 28.9 | 112 | | | 4.71 | 4.4 |

| 4.0 | 1.0 | 2.3 | 1000 | 29.6 | 21.1 | 1.98 | 36.3 | | 15.0 | 3.6 | 1100 | 37.9 | 2.12 | 30.7 | 102 | | | 5.25 | 4.5 |

80 | 6.0 | 2.2 | 5.1 | 730 | 29.6 | 18.6 | 1.76 | 35.6 | | 16.9 | 3.2 | 820 | 38.4 | 2.32 | 30.4 | 113 | | | 4.85 | 4.6 |

6.0 | 2.2 | 5.1 | 1000 | 30.8 | 21.7 | 1.86 | 37.1 | | 16.6 | 3.4 | 1100 | 39.6 | 2.14 | 32.3 | 103 | | | 5.41 | 4.7 |

| | | |

| 8.0 | 3.5 | 8.1 | 730 | 30.2 | 18.8 | 1.70 | 36.0 | | 17.7 | 3.0 | 820 | 39.3 | 2.34 | 31.2 | 114 | | | 4.93 | 4.8 |

| 8.0 | 3.5 | 8.1 | 1000 | 31.4 | 21.9 | 1.80 | 37.5 | | 17.4 | 3.1 | 1100 | 40.5 | 2.16 | 33.1 | 104 | | | 5.50 | 4.9 |

| 4.0 | 1.0 | 2.3 | 730 | 27.5 | 17.8 | 1.97 | 34.2 | | 13.9 | 3.9 | 820 | 38.3 | 2.32 | 30.3 | 113 | | | 4.84 | 4.6 |

| 4.0 | 1.0 | 2.3 | 1000 | 28.6 | 20.7 | 2.08 | 35.7 | | 13.7 | 4.1 | 1100 | 39.5 | 2.14 | 32.1 | 103 | | | 5.40 | 4.7 |

85 | 6.0 | 2.2 | 5.0 | 730 | 28.6 | 18.2 | 1.85 | 34.9 | | 15.4 | 3.6 | 820 | 40.1 | 2.35 | 31.9 | 115 | | | 5.00 | 4.8 |

6.0 | 2.2 | 5.0 | 1000 | 29.8 | 21.2 | 1.96 | 36.4 | | 15.2 | 3.8 | 1100 | 41.3 | 2.17 | 33.9 | 105 | | | 5.58 | 4.9 |

| | | |

| 8.0 | 3.5 | 8.0 | 730 | 29.2 | 18.5 | 1.80 | 35.3 | | 16.3 | 3.3 | 820 | 41.0 | 2.37 | 32.7 | 116 | | | 5.08 | 5.0 |

| 8.0 | 3.5 | 8.0 | 1000 | 30.4 | 21.5 | 1.90 | 36.8 | | 16.0 | 3.5 | 1100 | 42.3 | 2.19 | 34.8 | 106 | | | 5.67 | 5.1 |

| 4.0 | 1.0 | 2.3 | 730 | 26.5 | 17.4 | 2.07 | 33.6 | | 12.8 | 4.5 | 820 | 39.8 | 2.35 | 31.6 | 115 | | | 4.98 | 4.8 |

| 4.0 | 1.0 | 2.3 | 1000 | 27.5 | 20.2 | 2.19 | 35.0 | | 12.6 | 4.6 | 1100 | 41.1 | 2.17 | 33.6 | 105 | | | 5.55 | 4.9 |

90 | 6.0 | 2.1 | 4.9 | 730 | 27.6 | 17.8 | 1.95 | 34.3 | | 14.2 | 4.1 | 820 | 41.7 | 2.38 | 33.4 | 117 | | | 5.14 | 5.0 |

6.0 | 2.1 | 4.9 | 1000 | 28.7 | 20.7 | 2.06 | 35.8 | | 13.9 | 4.3 | 1100 | 43.0 | 2.20 | 35.5 | 106 | | | 5.73 | 5.1 |

| | | |

| 8.0 | 3.4 | 7.9 | 730 | 28.2 | 18.1 | 1.89 | 34.7 | | 14.9 | 3.8 | 820 | 42.7 | 2.40 | 34.3 | 118 | | | 5.23 | 5.2 |

| 8.0 | 3.4 | 7.9 | 1000 | 29.4 | 21.0 | 2.00 | 36.2 | | 14.7 | 4.0 | 1100 | 44.1 | 2.21 | 36.5 | 107 | | | 5.83 | 5.3 |

| 4.0 | 1.0 | 2.3 | 730 | 24.7 | 16.7 | 2.31 | 32.6 | | 10.7 | 4.9 | N/A | N/A | N/A | N/A | N/A | | | N/A | |

| 4.0 | 1.0 | 2.3 | 1000 | 25.7 | 19.5 | 2.44 | 34.0 | | 10.5 | 5.1 | N/A | N/A | N/A | N/A | N/A | | | N/A | |

100 | 6.0 | 2.0 | 4.6 | 730 | 25.7 | 17.1 | 2.17 | 33.1 | | 11.8 | 4.7 | N/A | N/A | N/A | N/A | N/A | | | N/A | |

6.0 | 2.0 | 4.6 | 1000 | 26.7 | 19.9 | 2.30 | 34.6 | | 11.6 | 4.9 | N/A | N/A | N/A | N/A | N/A | | | N/A | |

| | | | |

| 8.0 | 3.2 | 7.4 | 730 | 26.2 | 17.3 | 2.10 | 33.4 | | 12.5 | 4.5 | N/A | N/A | N/A | N/A | N/A | | | N/A | |

| 8.0 | 3.2 | 7.4 | 1000 | 27.3 | 20.1 | 2.23 | 34.9 | | 12.3 | 4.7 | N/A | N/A | N/A | N/A | N/A | | | N/A | |

| 4.0 | 0.9 | 2.1 | 730 | 23.2 | 16.4 | 2.59 | 32.1 | | 9.0 | 5.9 | N/A | N/A | N/A | N/A | N/A | | | N/A | |

| 4.0 | 0.9 | 2.1 | 1000 | 24.1 | 19.0 | 2.74 | 33.5 | | 8.8 | 6.1 | N/A | N/A | N/A | N/A | N/A | | | N/A | |

110 | 6.0 | 1.9 | 4.4 | 730 | 24.0 | 16.5 | 2.43 | 32.3 | | 9.9 | 5.7 | N/A | N/A | N/A | N/A | N/A | | | N/A | |

6.0 | 1.9 | 4.4 | 1000 | 24.9 | 19.2 | 2.57 | 33.7 | | 9.7 | 5.9 | N/A | N/AOperation | not recommended | | | N/A | |

| | | N/A | N/A | N/A | | | |

| 8.0 | 3.1 | 7.2 | 730 | 24.4 | 16.6 | 2.35 | 32.5 | | 10.4 | 5.5 | N/A | N/A | N/A | N/A | N/A | | | N/A | |

| 8.0 | 3.1 | 7.2 | 1000 | 25.4 | 19.4 | 2.49 | 33.9 | | 10.2 | 5.7 | N/A | N/A | N/A | N/A | N/A | | | N/A | |

| 4.0 | 0.9 | 2.1 | 730 | 22.0 | 16.1 | 2.87 | 31.9 | | 7.7 | 6.9 | N/A | N/A | N/A | N/A | N/A | | | N/A | |

| 4.0 | 0.9 | 2.1 | 1000 | 22.8 | 18.7 | 3.04 | 33.2 | | 7.5 | 7.2 | N/A | N/A | N/A | N/A | N/A | | | N/A | |

120 | 6.0 | 1.8 | 4.2 | 730 | 22.5 | 16.1 | 2.74 | 31.9 | | 8.2 | 6.7 | N/A | N/A | N/A | N/A | N/A | | | N/A | |

6.0 | 1.8 | 4.2 | 1000 | 23.4 | 18.8 | 2.90 | 33.3 | | 8.1 | 7.0 | N/A | N/A | N/A | N/A | N/A | | | N/A | |

| | | | |

| 8.0 | 3.0 | 6.9 | 730 | 22.7 | 16.2 | 2.67 | 31.9 | | 8.5 | 6.4 | N/A | N/A | N/A | N/A | N/A | | | N/A | |

| 8.0 | 3.0 | 6.9 | 1000 | 23.6 | 18.9 | 2.82 | 33.3 | | 8.4 | 6.7 | N/A | N/A | N/A | N/A | N/A | | | N/A | |

Interpolation is permissible; extrapolation is not.

All entering air conditions are 80°F DB and 67°F WB in cooling, and 70°F DB in heating.

AHRI/ISO certified conditions are 80.6°F DB and 66.2°F WB in cooling and 68°F DB in heating.

Table does not reflect fan or pump power corrections for AHRI/ISO conditions.

All performance is based upon the lower voltage of dual voltage rated units.

Operation below 40°F EWT is based upon a 15% methanol antifreeze solution.

Operation below 60°F EWT requires optional insulated water/refrigerant circuit.

See performance correction tables for operating conditions other than those listed above.

For operation in the shaded areas, please see the Performance Data Selection Notes.

| GT-PG | Bryant: Whatever it Takes. |

| 18 |

| |

| | |