OPERATION

OPERATION

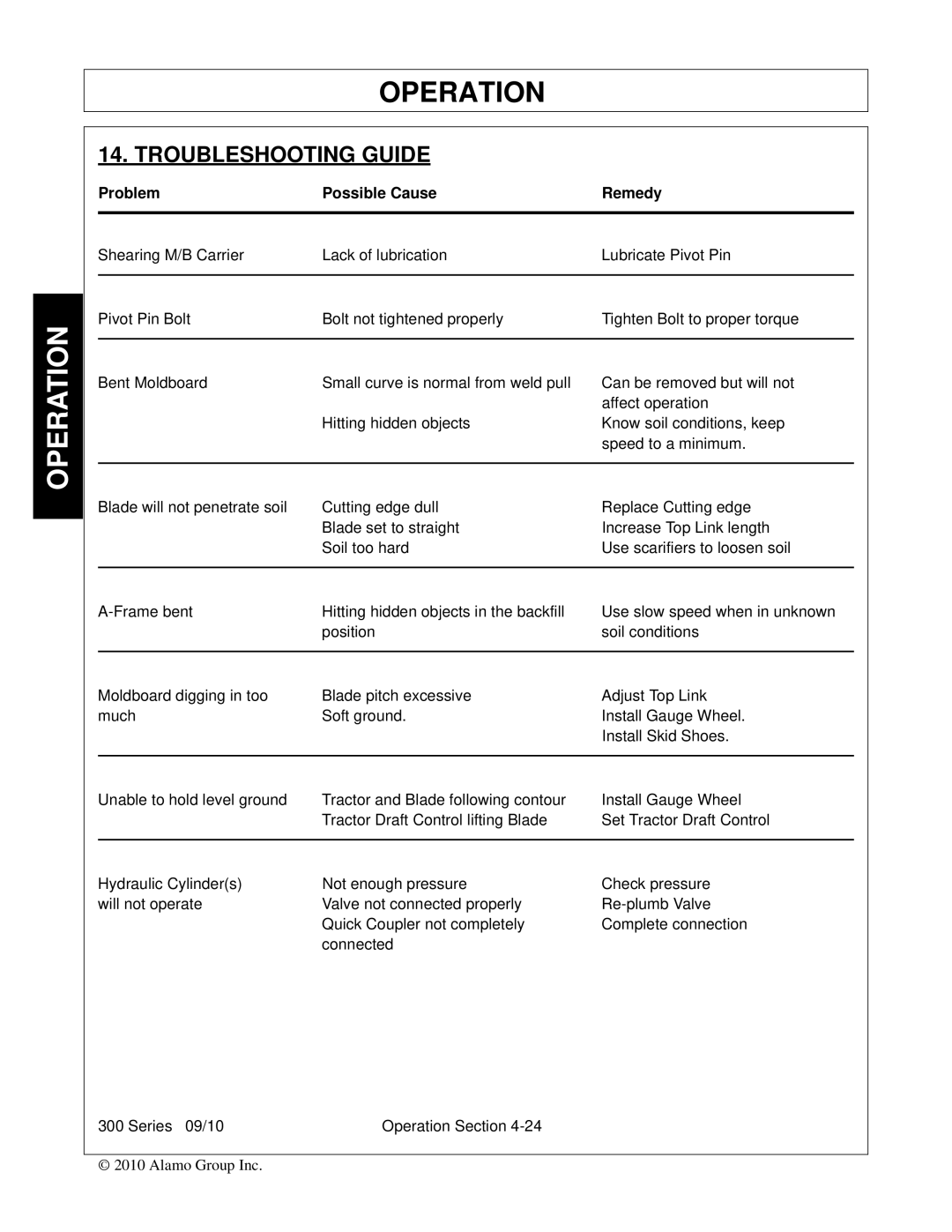

14. TROUBLESHOOTING GUIDE

Problem | Possible Cause | Remedy |

|

|

|

Shearing M/B Carrier | Lack of lubrication | Lubricate Pivot Pin |

|

|

|

Pivot Pin Bolt | Bolt not tightened properly | Tighten Bolt to proper torque |

|

|

|

Bent Moldboard | Small curve is normal from weld pull | Can be removed but will not |

|

| affect operation |

| Hitting hidden objects | Know soil conditions, keep |

|

| speed to a minimum. |

|

|

|

Blade will not penetrate soil | Cutting edge dull | Replace Cutting edge |

| Blade set to straight | Increase Top Link length |

| Soil too hard | Use scarifiers to loosen soil |

|

|

|

Hitting hidden objects in the backfill | Use slow speed when in unknown | |

| position | soil conditions |

|

|

|

Moldboard digging in too | Blade pitch excessive | Adjust Top Link |

much | Soft ground. | Install Gauge Wheel. |

|

| Install Skid Shoes. |

|

|

|

Unable to hold level ground | Tractor and Blade following contour | Install Gauge Wheel |

| Tractor Draft Control lifting Blade | Set Tractor Draft Control |

|

|

|

Hydraulic Cylinder(s) | Not enough pressure | Check pressure |

will not operate | Valve not connected properly | |

| Quick Coupler not completely | Complete connection |

| connected |

|

300 Series 09/10 | Operation Section |

© 2010 Alamo Group Inc.