ASSEMBLY

ASSEMBLY

Suggestions to increase stability:

•Increasing rear wheel track; a tractor with a wider wheel track is more stable.

•Ballasting the wheel; it is preferable to use external weights but liquid can be added to around 75% of the tire volume – water with

•Addition of weights – care should be taken in selecting the location of the weights to ensure they are added to a position that offers the greatest advantage.

•Front axle locking; a ram can be used to ‘lock’ the front axle in work only – locking the axle moves the ‘balance line’ and can be used to transfer weight to the front axle from the rear (check with tractor

manufacturer).

The advice above is offered as a guide for stability only and is not a guide to tractor strength - it is therefore recommended that you consult your tractor manufacturer or local dealer to obtain specific advise on this subject, additionally advice should be sought from a tire specialist with regard to tire pressures and ratings suitable for the type and nature of the machine you intend to fit.

DEALER SETUP INSTRUCTIONS

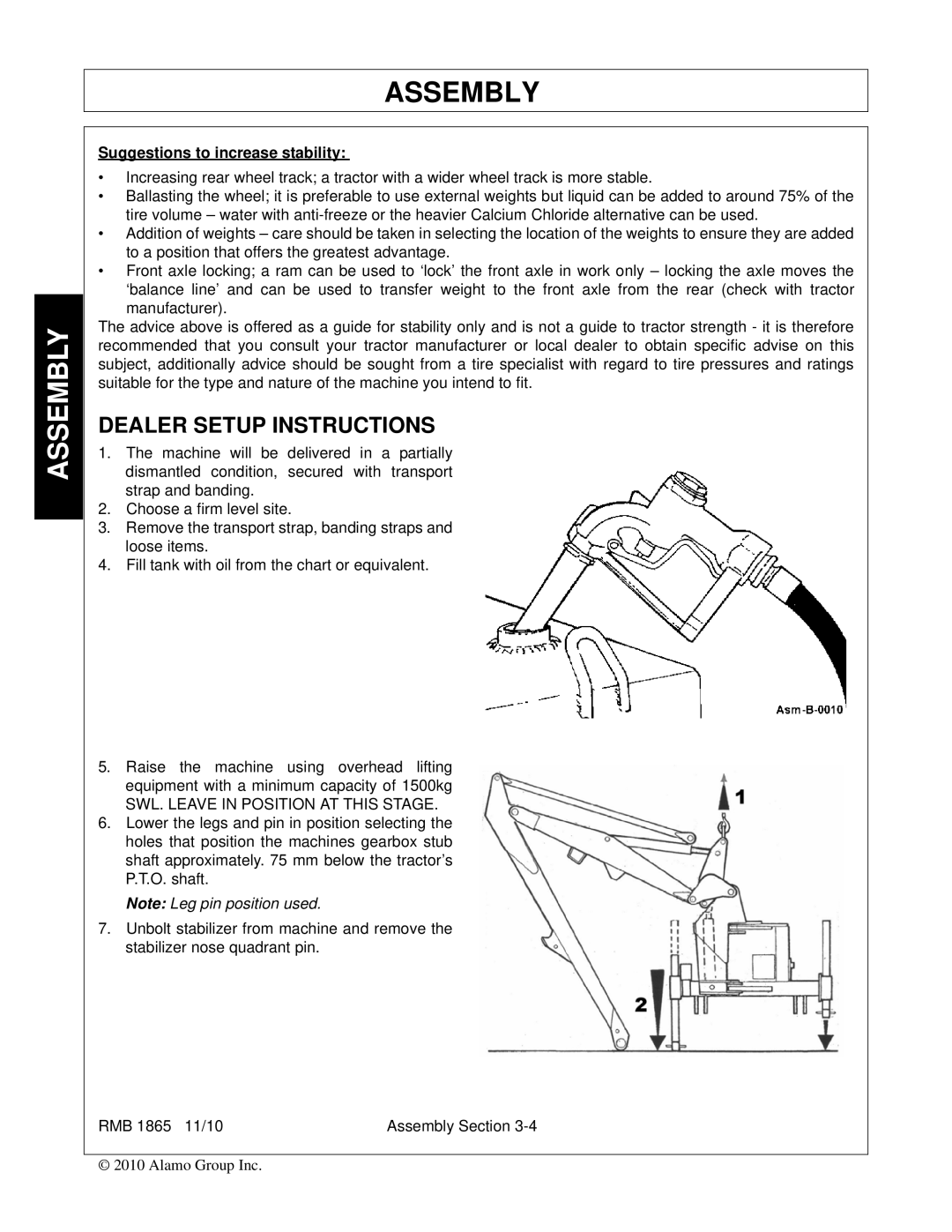

1.The machine will be delivered in a partially dismantled condition, secured with transport strap and banding.

2.Choose a firm level site.

3.Remove the transport strap, banding straps and loose items.

4.Fill tank with oil from the chart or equivalent.

5.Raise the machine using overhead lifting equipment with a minimum capacity of 1500kg

SWL. LEAVE IN POSITION AT THIS STAGE.

6.Lower the legs and pin in position selecting the holes that position the machines gearbox stub shaft approximately. 75 mm below the tractor’s P.T.O. shaft.

Note: Leg pin position used.

7.Unbolt stabilizer from machine and remove the stabilizer nose quadrant pin.

RMB 1865 11/10 | Assembly Section |

© 2010 Alamo Group Inc.