OPERATION

OPERATION

10. WIRE TRAP

The flail head is equipped with a wire cutting edge welded into the underside. This is to ensure that the ends of any wire that may be entwined in the rotor are cut and fall within the confines of the flail head. This plate should not be interfered with in any way. Any wire caught in the rotor must be immediately removed (see below).

REMOVING WIRE

•Select rotor 'OFF' and wait until it has stopped rotating.

•STOP the tractor and only then remove wire.

•Do not reverse the rotor in an attempt to unwind any wire.

11. Rotor Operating Speed

Ensure that the rotor control lever is in the ‘STOP’ position before engaging the PTO shaft. Allow the oil to circulate for a minute or so before operating the armhead levers. Position the fail head in a safe position, increase the engine speed to a high idle and move rotor control lever to ‘START’. After initial surging the rotor will run at an even speed.

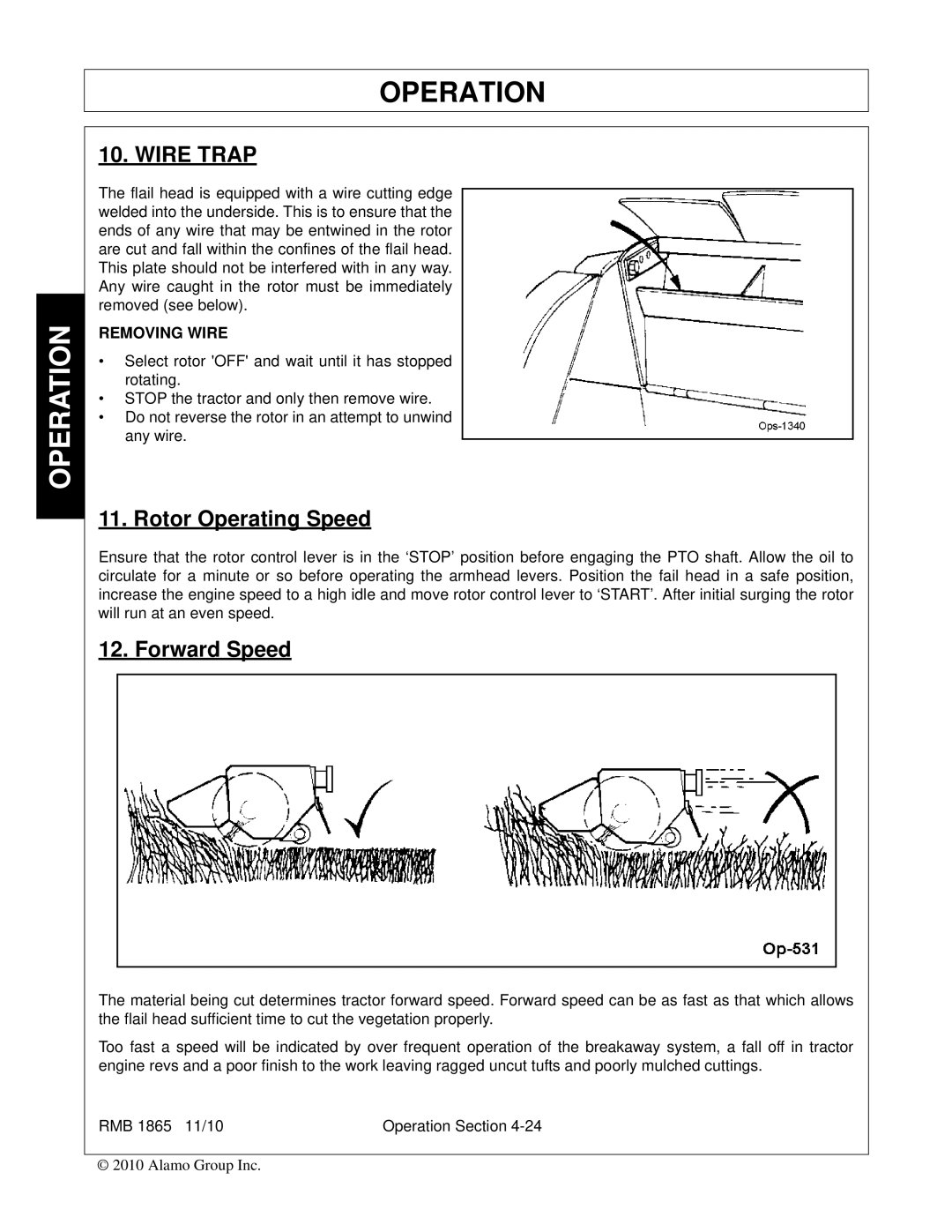

12. Forward Speed

The material being cut determines tractor forward speed. Forward speed can be as fast as that which allows the flail head sufficient time to cut the vegetation properly.

Too fast a speed will be indicated by over frequent operation of the breakaway system, a fall off in tractor engine revs and a poor finish to the work leaving ragged uncut tufts and poorly mulched cuttings.

RMB 1865 11/10 | Operation Section |

© 2010 Alamo Group Inc.