Manual de Instrucciones | CHN10101AV |

Operating Instructions | CHN10101AV |

Cómo usar la

Clavadora (Continuación)

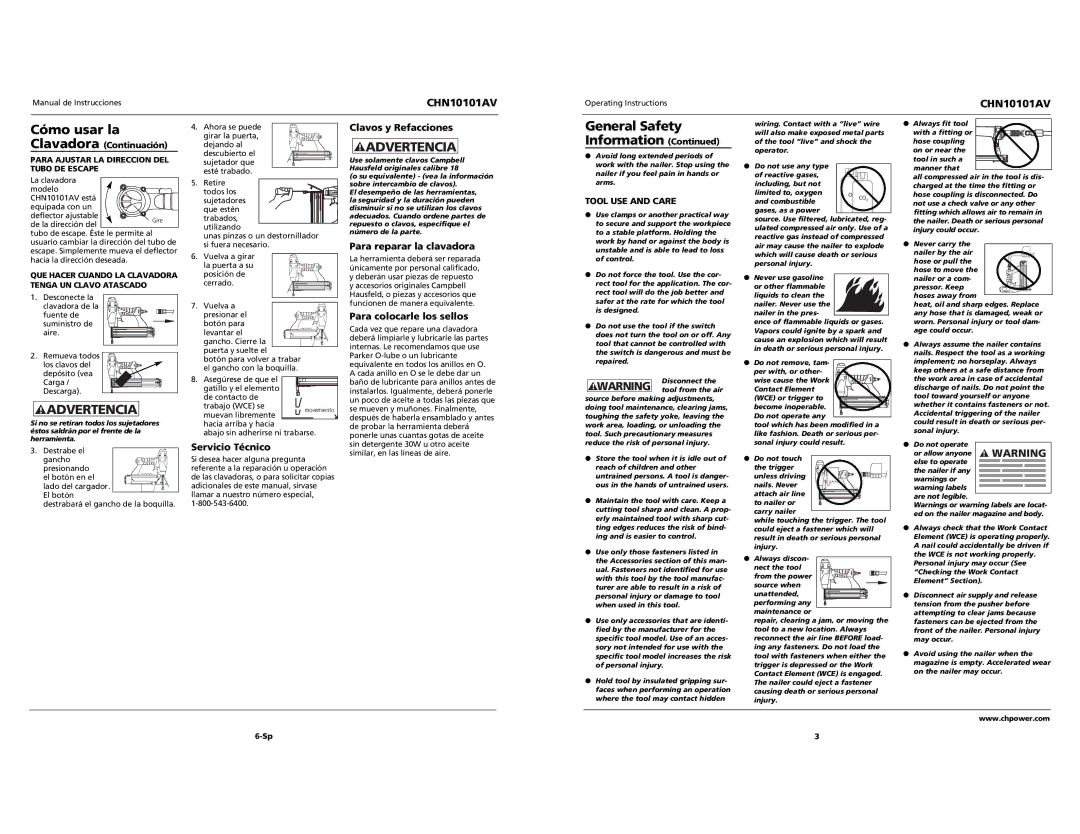

PARA AJUSTAR LA DIRECCION DEL TUBO DE ESCAPE

La clavadora modelo CHN10101AV está equipada con un deflector ajustable

4.Ahora se puede girar la puerta, dejando al descubierto el sujetador que esté trabado.

5.Retire

todos los sujetadores que estén trabados,

Clavos y Refacciones

!ADVERTENCIA

Use solamente clavos Campbell Hausfeld originales calibre 18

(o su equivalente) - (vea la información sobre intercambio de clavos).

El desempeño de las herramientas, la seguridad y la duración pueden disminuir si no se utilizan los clavos adecuados. Cuando ordene partes de

General Safety Information (Continued)

●Avoid long extended periods of work with the nailer. Stop using the nailer if you feel pain in hands or arms.

TOOL USE AND CARE

● Use clamps or another practical way |

wiring. Contact with a “live” wire will also make exposed metal parts of the tool “live” and shock the operator.

●Do not use any type

of reactive gases, including, but not limited to, oxygen and combustible gases, as a power

●Always fit tool

with a fitting or hose coupling

on or near the tool in such a manner that

all compressed air in the tool is dis- charged at the time the fitting or hose coupling is disconnected. Do not use a check valve or any other fitting which allows air to remain in

de la dirección del

Gire

utilizando

repuesto o clavos, especifique el

to secure and support the workpiece |

source. Use filtered, lubricated, reg- ulated compressed air only. Use of a

the nailer. Death or serious personal injury could occur.

tubo de escape. Éste le permite al usuario cambiar la dirección del tubo de escape. Simplemente mueva el deflector hacia la dirección deseada.

QUE HACER CUANDO LA CLAVADORA TENGA UN CLAVO ATASCADO

1. Desconecte la clavadora de la fuente de suministro de aire.

2. Remueva todos los clavos del depósito (vea Carga / Descarga).

!ADVERTENCIA

Si no se retiran todos los sujetadores éstos saldrán por el frente de la herramienta.

3. | Destrabe el |

| gancho |

| presionando |

| el botón en el |

| lado del cargador. |

| El botón |

| destrabará el gancho de la boquilla. |

unas pinzas o un destornillador si fuera necesario.

6.Vuelva a girar la puerta a su posición de

cerrado.

7. Vuelva a presionar el botón para levantar el gancho. Cierre la puerta y suelte el

botón para volver a trabar el gancho con la boquilla.

8.Asegúrese de que el gatillo y el elemento de contacto de

trabajo (WCE) se | movemiento | |

muevan libremente | ||

|

hacia arriba y hacia

abajo sin adherirse ni trabarse.

Servicio Técnico

Si desea hacer alguna pregunta referente a la reparación u operación de las clavadoras, o para solicitar copias adicionales de este manual, sírvase llamar a nuestro número especial,

número de la parte.

Para reparar la clavadora

La herramienta deberá ser reparada únicamente por personal calificado, y deberán usar piezas de repuesto y accesorios originales Campbell Hausfeld, o piezas y accesorios que funcionen de manera equivalente.

Para colocarle los sellos

Cada vez que repare una clavadora deberá limpiarle y lubricarle las partes internas. Le recomendamos que use Parker

to a stable platform. Holding the |

work by hand or against the body is |

unstable and is able to lead to loss |

of control. |

● Do not force the tool. Use the cor- |

rect tool for the application. The cor- |

rect tool will do the job better and |

safer at the rate for which the tool |

is designed. |

● Do not use the tool if the switch |

does not turn the tool on or off. Any |

tool that cannot be controlled with |

the switch is dangerous and must be |

repaired. |

Disconnect the

! WARNING tool from the air source before making adjustments, doing tool maintenance, clearing jams, toughing the safety yoke, leaving the work area, loading, or unloading the tool. Such precautionary measures reduce the risk of personal injury.

●Store the tool when it is idle out of reach of children and other untrained persons. A tool is danger- ous in the hands of untrained users.

●Maintain the tool with care. Keep a cutting tool sharp and clean. A prop- erly maintained tool with sharp cut- ting edges reduces the risk of bind- ing and is easier to control.

●Use only those fasteners listed in the Accessories section of this man- ual. Fasteners not identified for use with this tool by the tool manufac- turer are able to result in a risk of personal injury or damage to tool when used in this tool.

●Use only accessories that are identi- fied by the manufacturer for the specific tool model. Use of an acces- sory not intended for use with the specific tool model increases the risk of personal injury.

●Hold tool by insulated gripping sur- faces when performing an operation where the tool may contact hidden

reactive gas instead of compressed air may cause the nailer to explode which will cause death or serious personal injury.

●Never use gasoline

or other flammable liquids to clean the nailer. Never use the

nailer in the pres-

ence of flammable liquids or gases. Vapors could ignite by a spark and cause an explosion which will result in death or serious personal injury.

●Do not remove, tam- per with, or other- wise cause the Work Contact Element (WCE) or trigger to become inoperable. Do not operate any

tool which has been modified in a like fashion. Death or serious per- sonal injury could result.

●Do not touch the trigger unless driving nails. Never attach air line to nailer or carry nailer

while touching the trigger. The tool could eject a fastener which will result in death or serious personal injury.

●Always discon- nect the tool

from the power source when unattended, performing any maintenance or

repair, clearing a jam, or moving the tool to a new location. Always reconnect the air line BEFORE load- ing any fasteners. Do not load the tool with fasteners when either the trigger is depressed or the Work Contact Element (WCE) is engaged. The nailer could eject a fastener causing death or serious personal injury.

●Never carry the nailer by the air hose or pull the hose to move the nailer or a com- pressor. Keep hoses away from

heat, oil and sharp edges. Replace any hose that is damaged, weak or worn. Personal injury or tool dam- age could occur.

●Always assume the nailer contains nails. Respect the tool as a working implement; no horseplay. Always keep others at a safe distance from the work area in case of accidental discharge of nails. Do not point the tool toward yourself or anyone whether it contains fasteners or not. Accidental triggering of the nailer could result in death or serious per- sonal injury.

●Do not operate

or allow anyone else to operate the nailer if any warnings or warning labels are not legible.

Warnings or warning labels are locat- ed on the nailer magazine and body.

●Always check that the Work Contact Element (WCE) is operating properly. A nail could accidentally be driven if the WCE is not working properly.

Personal injury may occur (See “Checking the Work Contact Element” Section).

●Disconnect air supply and release tension from the pusher before attempting to clear jams because fasteners can be ejected from the front of the nailer. Personal injury may occur.

●Avoid using the nailer when the magazine is empty. Accelerated wear on the nailer may occur.

www.chpower.com

3 |