Further Safety | | maximum safety, so the least | 2. | If the use of a guard is |

| amount of wheel is exposed | | | recommended for wire brushing, do |

Instructions For All | | | |

| towards the operator. The guard | | | not allow any interference of the |

Operations (Cont.) | | helps to protect operator from | | | wire wheel or brush with the guard. |

| broken wheel fragments and | | | Wire wheel or brush may expand in |

power tool to be forced in the | | accidental contact with wheel. | | | diameter due to work load and |

direction opposite of the accessory’s | 2. Use only wheel types that are | | | centrifugal forces. |

rotation at the point of the binding. | | | | | |

| recommended for your power tool | | | | | |

For example, if an abrasive wheel is | | | | | | |

| and the specific guard designed for | | Assembly |

snagged or pinched by the workpiece, | | the selected wheel. Wheels for | |

the edge of the wheel that is entering | | which the power tool was not | | INSTALLING THE SIDE HANDLE |

into the pinch point can dig into the | | |

| designed cannot be adequately | 1. | UNPLUG YOUR GRINDER. |

surface of the material causing the | | guarded and are unsafe. |

wheel to climb out or kick out. The | 3. Wheels must be used only for | 2. | Install the side handle by screwing |

wheel may either jump toward or away | | | it into the side of the gear housing. |

| recommended applications. For | | |

from the operator, depending on | | | | | | |

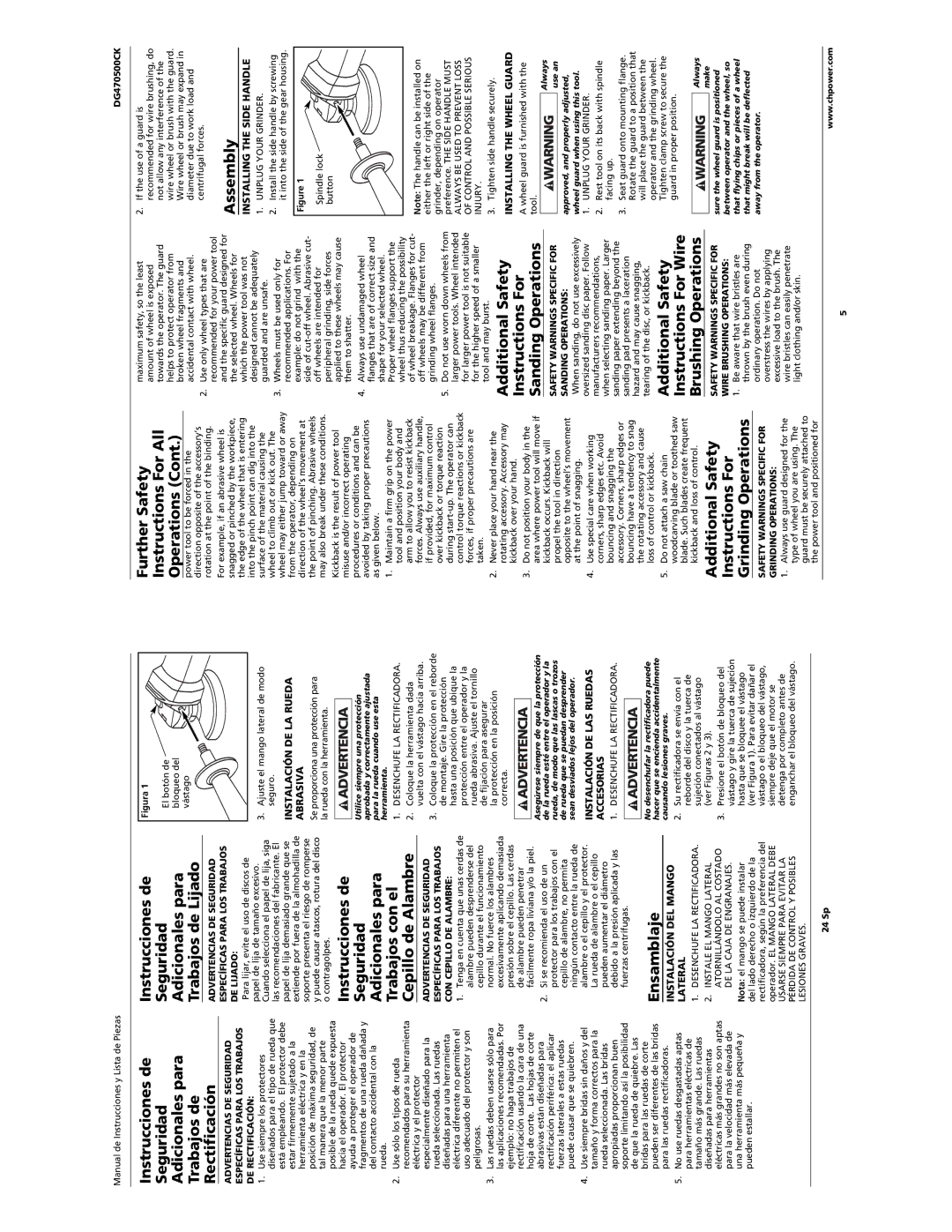

direction of the wheel’s movement at | | example: do not grind with the | | Figure 1 |

| side of cut-off wheel. Abrasive cut- | |

the point of pinching. Abrasive wheels | | | | | | |

| off wheels are intended for | | | Spindle lock |

may also break under these conditions. | | | |

Kickback is the result of power tool | | peripheral grinding, side forces | | | button |

| applied to these wheels may cause | | | | | |

misuse and/or incorrect operating | | them to shatter. | | | | | |

procedures or conditions and can be | 4. Always use undamaged wheel | | | | | |

avoided by taking proper precautions | | | | | |

| flanges that are of correct size and | | | | | |

as given below. | | | | | | |

| shape for your selected wheel. | | | | | |

1. Maintain a firm grip on the power | | | | | | |

| Proper wheel flanges support the | | | | | |

tool and position your body and | | wheel thus reducing the possibility | | | | | |

arm to allow you to resist kickback | | of wheel breakage. Flanges for cut- | | Note: The handle can be installed on |

forces. Always use auxiliary handle, | | off wheels may be different from | |

if provided, for maximum control | | grinding wheel flanges. | | either the left or right side of the |

over kickback or torque reaction | 5. Do not use worn down wheels from | | grinder, depending on operator |

during start-up. The operator can | | preference. THE SIDE HANDLE MUST |

| larger power tools. Wheel intended | |

control torque reactions or kickback | | | ALWAYS BE USED TO PREVENT LOSS |

| for larger power tool is not suitable | |

forces, if proper precautions are | | | OF CONTROL AND POSSIBLE SERIOUS |

| for the higher speed of a smaller | |

taken. | | | INJURY. |

| tool and may burst. | |

2. Never place your hand near the | | 3. | Tighten side handle securely. |

| Additional Safety |

rotating accessory. Accessory may | | | INSTALLING THE WHEEL GUARD |

kickback over your hand. | | Instructions For | |

| | A wheel guard is furnished with the |

3. Do not position your body in the | | |

| Sanding Operations | | tool. |

area where power tool will move if | | |

kickback occurs. Kickback will | | | | | | | Always |

| SAFETY WARNINGS SPECIFIC FOR | | |

propel the tool in direction | | | | | | use an |

opposite to the wheel’s movement | | SANDING OPERATIONS: | | approved, and properly adjusted, |

at the point of snagging. | | When sanding, do not use excessively | | wheel guard when using this tool. |

4. Use special care when working | | oversized sanding disc paper. Follow | 1. | UNPLUG YOUR GRINDER. |

| manufacturers recommendations, | 2. | Rest tool on its back with spindle |

corners, sharp edges etc. Avoid | |

| when selecting sanding paper. Larger |

bouncing and snagging the | | | | facing up. |

| sanding paper extending beyond the | | |

accessory. Corners, sharp edges or | | 3. | Seat guard onto mounting flange. |

| sanding pad presents a laceration |

bouncing have a tendency to snag | | | | Rotate the guard to a position that |

| hazard and may cause snagging, | | |

the rotating accessory and cause | | | | will place the guard between the |

| tearing of the disc, or kickback. | | |

loss of control or kickback. | | | | operator and the grinding wheel. |

| Additional Safety | | |

5. Do not attach a saw chain | | | | Tighten clamp screw to secure the |

woodcarving blade or toothed saw | | Instructions For Wire | | | guard in proper position. |

blade. Such blades create frequent | | | | | | |

kickback and loss of control. | | Brushing Operations | | | | | Always |

| | | | |

Additional Safety | | | | | | | make |

| SAFETY WARNINGS SPECIFIC FOR | | |

| | sure the wheel guard is positioned |

Instructions For | | WIRE BRUSHING OPERATIONS: | | between operator and the wheel, so |

Grinding Operations | | 1. Be aware that wire bristles are | | that flying chips or pieces of a wheel |

| thrown by the brush even during | | that might break will be deflected |

SAFETY WARNINGS SPECIFIC FOR | | ordinary operation. Do not | | away from the operator. |

| overstress the wires by applying | | | | | |

GRINDING OPERATIONS: | | | | | | |

| excessive load to the brush. The | | | | | |

1. Always use guard designed for the | | | | | | |

| wire bristles can easily penetrate | | | | | |

type of wheel you are using. The | | light clothing and/or skin. | | | | | |

guard must be securely attached to | | | | | | | |

the power tool and positioned for | | | | | | | |