Funcionamiento

(Continuación)

alcancen la máxima velocidad. Baje gradualmente la rectificadora hasta que la rueda abrasiva entre en contacto con la pieza de trabajo.

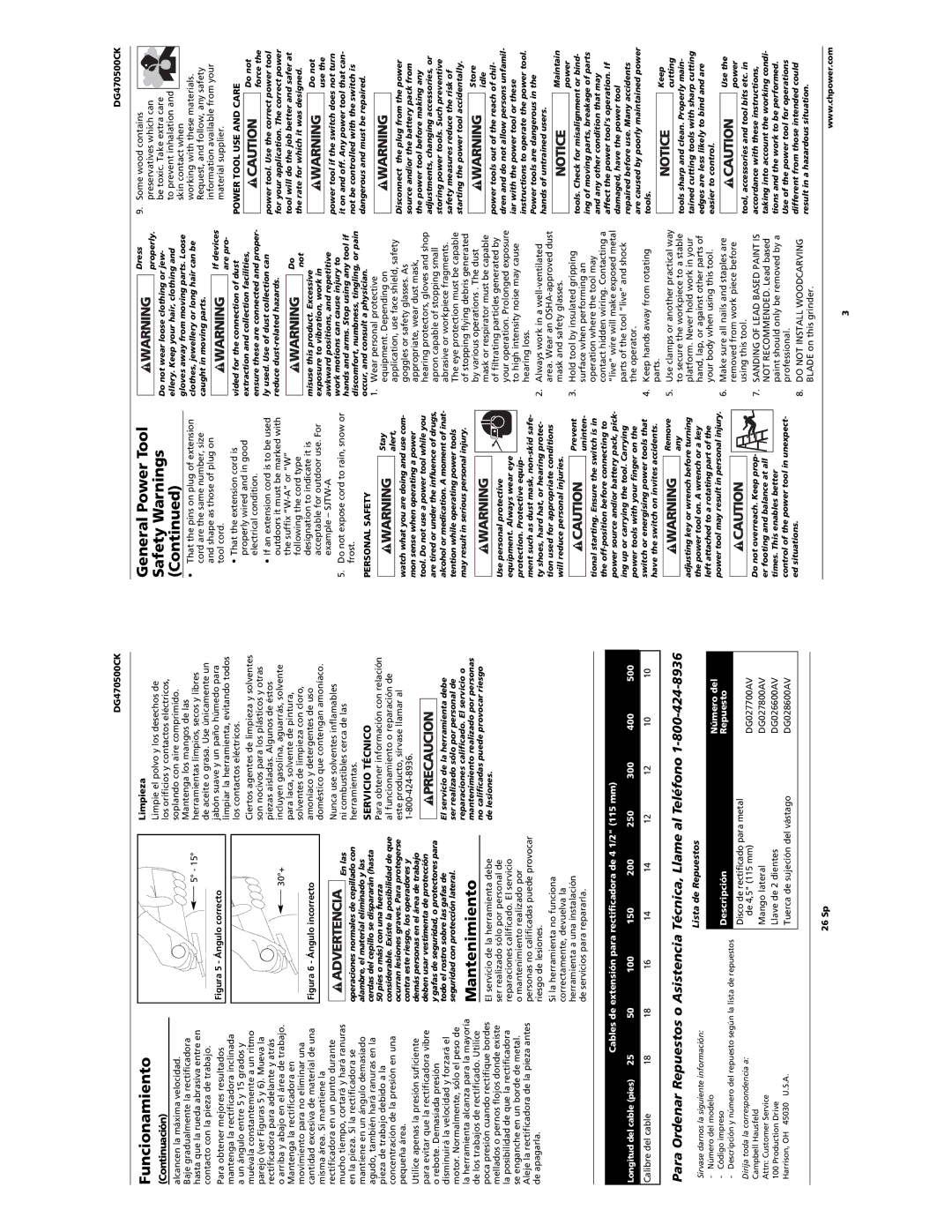

Para obtener mejores resultados mantenga la rectificadora inclinada a un ángulo entre 5 y 15 grados y muévala constantemente a un ritmo parejo (ver Figuras 5 y 6). Mueva la rectificadora para adelante y atrás

o arriba y abajo en el área de trabajo. Mantenga la rectificadora en movimiento para no eliminar una cantidad excesiva de material de una misma área. Si mantiene la rectificadora en un punto durante mucho tiempo, cortará y hará ranuras en la pieza. Si la rectificadora se mantiene en un ángulo demasiado agudo, también hará ranuras en la pieza de trabajo debido a la concentración de la presión en una pequeña área.

Utilice apenas la presión suficiente para evitar que la rectificadora vibre o rebote. Demasiada presión disminuirá la velocidad y forzará el motor. Normalmente, sólo el peso de la herramienta alcanza para la mayoría de los trabajos de rectificado. Utilice poca presión cuando rectifique bordes mellados o pernos flojos donde existe la posibilidad de que la rectificadora se enganche en un borde de metal. Aleje la rectificadora de la pieza antes de apagarla.

5° - 15°

5° - 15°

Figura 5 - Ángulo correcto

30°+

30°+

Figura 6 - Ángulo incorrecto

En las operaciones normales de cepillado con alambre, el material eliminado y las cerdas del cepillo se dispararán (hasta 50 pies o más) con una fuerza considerable. Existe la posibilidad de que ocurran lesiones graves. Para protegerse contra este riesgo, los operadores y demás personas en el área de trabajo deben usar vestimenta de protección

En las operaciones normales de cepillado con alambre, el material eliminado y las cerdas del cepillo se dispararán (hasta 50 pies o más) con una fuerza considerable. Existe la posibilidad de que ocurran lesiones graves. Para protegerse contra este riesgo, los operadores y demás personas en el área de trabajo deben usar vestimenta de protección

y gafas de seguridad, o protectores para todo el rostro sobre las gafas de seguridad con protección lateral.

Mantenimiento

El servicio de la herramienta debe ser realizado sólo por personal de reparaciones calificado. El servicio o mantenimiento realizado por personas no calificadas puede provocar riesgo de lesiones.

Si la herramienta no funciona correctamente, devuelva la herramienta a una instalación de servicios para repararla.

Limpieza

Limpie el polvo y los desechos de los orificios y contactos eléctricos, soplando con aire comprimido.

Mantenga los mangos de las herramientas limpios, secos y libres de aceite o grasa. Use únicamente un jabón suave y un paño húmedo para limpiar la herramienta, evitando todos los contactos eléctricos.

Ciertos agentes de limpieza y solventes son nocivos para los plásticos y otras piezas aisladas. Algunos de éstos incluyen gasolina, aguarrás, solvente para laca, solvente de pintura, solventes de limpieza con cloro, amoníaco y detergentes de uso doméstico que contengan amoníaco.

Nunca use solventes inflamables ni combustibles cerca de las herramientas.

SERVICIO TÉCNICO

Para obtener información con relación al funcionamiento o reparación de este producto, sírvase llamar al 1-800-424-8936.

El servicio de la herramienta debe ser realizado sólo por personal de reparaciones calificado. El servicio o mantenimiento realizado por personas no calificadas puede provocar riesgo de lesiones.

General Power Tool Safety Warnings (Continued)

•That the pins on plug of extension cord are the same number, size and shape as those of plug on tool cord.

•That the extension cord is properly wired and in good electrical condition.

•If an extension cord is to be used outdoors it must be marked with the suffix “W-A” or “W” following the cord type designation to indicate it is acceptable for outdoor use. For example – SJTW-A

5.Do not expose cord to rain, snow or frost.

PERSONAL SAFETY

Stay alert,

watch what you are doing and use com- mon sense when operating a power tool. Do not use a power tool while you are tired or under the influence of drugs, alcohol or medication. A moment of inat- tention while operating power tools may result in serious personal injury.

Use personal protective equipment. Always wear eye protection. Protective equip-

ment such as dust mask, non-skid safe- ty shoes, hard hat, or hearing protec- tion used for appropriate conditions will reduce personal injuries.

Prevent uninten- tional starting. Ensure the switch is in

Dress

properly.

Do not wear loose clothing or jew- ellery. Keep your hair, clothing and gloves away from moving parts. Loose clothes, jewellery or long hair can be caught in moving parts.

If devices are pro-

vided for the connection of dust extraction and collection facilities, ensure these are connected and proper- ly used. Use of dust collection can reduce dust-related hazards.

Do

not

misuse this product. Excessive exposure to vibration, work in awkward positions, and repetitive work motions can cause injury to hands and arms. Stop using any tool if discomfort, numbness, tingling, or pain occur, and consult a physician.

1. Wear personal protective |

equipment. Depending on |

application, use face shield, safety |

goggles or safety glasses. As |

appropriate, wear dust mask, |

hearing protectors, gloves and shop |

apron capable of stopping small |

abrasive or workpiece fragments. |

The eye protection must be capable |

of stopping flying debris generated |

by various operations . The dust |

mask or respirator must be capable |

of filtrating particles generated by |

your operation. Prolonged exposure |

to high intensity noise may cause |

hearing loss. |

2. Always work in a well-ventilated |

area. Wear an OSHA-approved dust |

mask and safety glasses. |

3. Hold tool by insulated gripping |

surface when performing an |

operation where the tool may |

9. Some wood contains preservatives which can be toxic. Take extra care

to prevent inhalation and skin contact when working with these materials. Request, and follow, any safety information available from your material supplier.

POWER TOOL USE AND CARE

Do not force the

power tool. Use the correct power tool for your application. The correct power tool will do the job better and safer at the rate for which it was designed.

Do not use the power tool if the switch does not turn

it on and off. Any power tool that can- not be controlled with the switch is dangerous and must be repaired.

Disconnect the plug from the power source and/or the battery pack from the power tool before making any adjustments, changing accessories, or storing power tools. Such preventive safety measures reduce the risk of starting the power tool accidentally.

Store idle

power tools out of the reach of chil- dren and do not allow persons unfamil- iar with the power tool or these instructions to operate the power tool. Power tools are dangerous in the hands of untrained users.

Maintain power

tools. Check for misalignment or bind- ing of moving parts, breakage of parts and any other condition that may

Sirvase darnos la siguiente información:

-Número del modelo

-Código impreso

-Descripción y número del repuesto según la lista de repuestos

Dirija toda la correspondencia a:

Campbell Hausfeld

Attn: Customer Service

100 Production Drive

Harrison, OH 45030 U.S.A.

Lista de Repuestos

| Número del |

Descripción | Repuesto |

| |

Disco de rectificado para metal | |

de 4,5" (115 mm) | DG027700AV |

Mango lateral | DG027800AV |

Llave de 2 dientes | DG026600AV |

Tuerca de sujeción del vástago | DG028600AV |

| |

adjusting key or wrench before turning the power tool on. A wrench or a key left attached to a rotating part of the power tool may result in personal injury.

Do not overreach. Keep prop- er footing and balance at all

times. This enables better

control of the power tool in unexpect- ed situations.

| platform. Never hold work in your |

| hand, lap, or against other parts of |

| your body when using this tool. |

6. | Make sure all nails and staples are |

| removed from work piece before |

| using this tool. |

7. | SANDING OF LEAD BASED PAINT IS |

| NOT RECOMMENDED. Lead based |

| paint should only be removed by a |

| professional. |

8. | DO NOT INSTALL WOODCARVING |

| BLADE on this grinder. |

tained cutting tools with sharp cutting edges are less likely to bind and are easier to control.

Use the power

tool, accessories and tool bits etc. in accordance with these instructions, taking into account the working condi- tions and the work to be performed. Use of the power tool for operations different from those intended could result in a hazardous situation.