Operating Instructions | FP2000, FP2012 |

General Safety (Continued)

18. Use a face

mask/respirator when spraying and spray in a well ventilated area

to prevent health and fire hazards.

19.Do not direct paint or other sprayed material at the compressor. Locate compressor as far away from the spraying area as possible to minimize overspray accumulation on the compressor.

20.When spraying with solvent of toxic chemicals, follow instructions provided by the chemical manufacturer.

Assembly

HOSE (MAY NOT BE SUPPLIED WITH UNIT)

Use an air hose with at least 140 PSI rating. Assemble the hose to hose connector or manifold and tighten snugly with a wrench.

Preparation

LUBRICATION

THIS UNIT

NOTICE CONTAINS NO OIL! Fill the crankcase to the full line on the dipstick before turning unit on. Crankcase requires 7.1 fluid oz. (210 ml) of oil to fill. Operating without oil, even for just a few seconds will damage the pump.

Use Chevron synthetic

1.Check and tighten all bolts, fittings, etc., before operating compressor.

2.Operate compressor in a ventilated area so that compressor may be properly cooled.

3.Locate compressor on a level surface where it can be directly plugged

into an outlet. If accidentally bumped, ensure compressor will not fall on anyone or anything.

4.If extension cord is used, refer to chart on page 3 to select the appropriate cord.

5.To avoid loss of power and overheating, use additional air hose instead of extension cords to reach work area.

WIRING

Local electrical wiring codes differ from area to area. Source wiring, plug and protector must be rated for at least the amperage and voltage indicated on motor nameplate and meet all electrical codes for this minimum.

NOTE: This compressor unit may be operated on a 115 volt, 15 amp circuit if the following conditions are met:

1.No other electrical appliances or lights are connected to the same branch circuit.

2.Voltage supply is normal.

3.Extension cords are of the minimum gauge specified in this instruction manual.

4.Circuit is equipped with a 15 amp circuit breaker or a 15 amp slow blow type fuse.

If previous conditions cannot be met or if nuisance tripping of current protection device occurs, operate compressor from a 115 volt, 20 amp circuit.

! CAUTION

Overheating, short circuiting and fire damage will result from inadequate wiring, etc.

GROUNDING INSTRUCTIONS

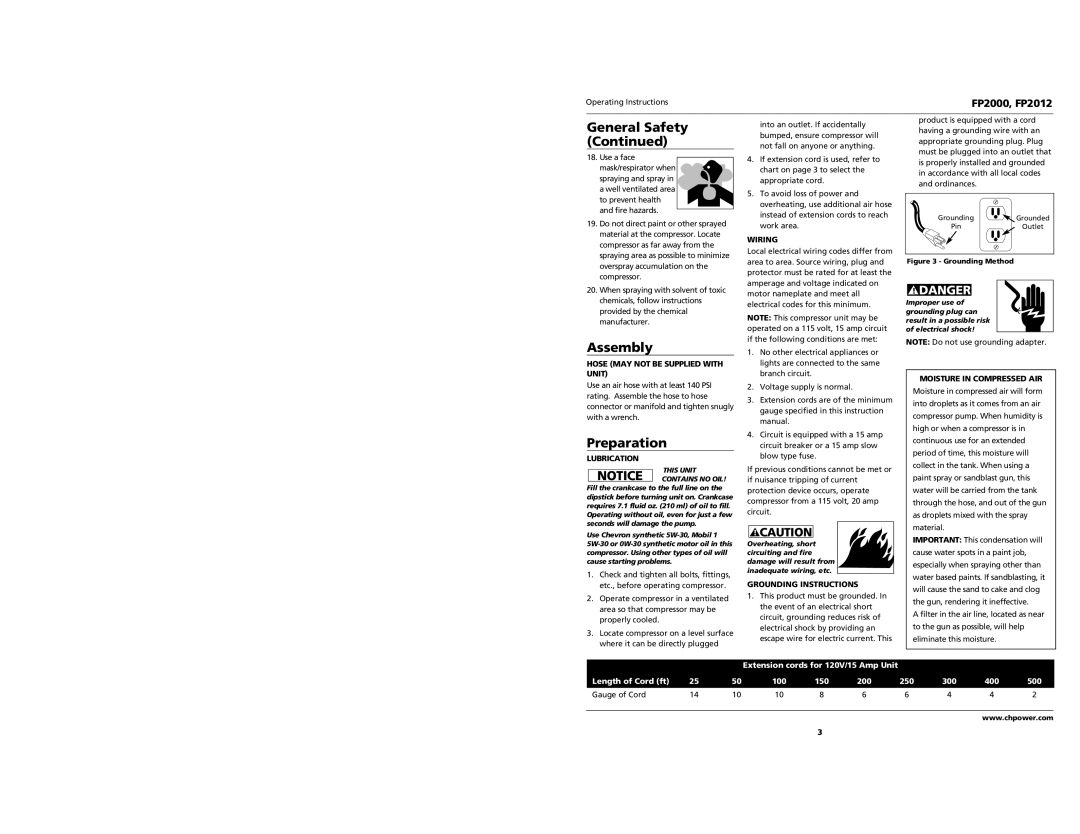

1.This product must be grounded. In the event of an electrical short circuit, grounding reduces risk of electrical shock by providing an escape wire for electric current. This

product is equipped with a cord having a grounding wire with an appropriate grounding plug. Plug must be plugged into an outlet that is properly installed and grounded in accordance with all local codes and ordinances.

Grounding |

|

| Grounded |

Pin | TEST | RESET | Outlet |

|

|

Figure 3 - Grounding Method

!DANGER

Improper use of grounding plug can result in a possible risk of electrical shock!

NOTE: Do not use grounding adapter.

MOISTURE IN COMPRESSED AIR

Moisture in compressed air will form into droplets as it comes from an air compressor pump. When humidity is high or when a compressor is in continuous use for an extended period of time, this moisture will collect in the tank. When using a paint spray or sandblast gun, this water will be carried from the tank through the hose, and out of the gun as droplets mixed with the spray material.

IMPORTANT: This condensation will cause water spots in a paint job, especially when spraying other than water based paints. If sandblasting, it will cause the sand to cake and clog the gun, rendering it ineffective.

A filter in the air line, located as near to the gun as possible, will help eliminate this moisture.

|

|

| Extension cords for 120V/15 Amp Unit |

|

|

|

| ||

Length of Cord (ft) | 25 | 50 | 100 | 150 | 200 | 250 | 300 | 400 | 500 |

Gauge of Cord | 14 | 10 | 10 | 8 | 6 | 6 | 4 | 4 | 2 |

www.chpower.com

3