Instalación

(Continuación)

6.La perilla de la válvula de presión/sifón se debe apretar en el mismo sentido de las agujas del reloj (dirección S) cuando haga las conexiones mostradas en la Figura 4 para usar un tanque de pintura a presión. Ésto evitará la fuga de aire a través del orificio de la válvula del envase cuando no lo esté usando.

CONVERSIÓN SIN PURGADOR A PURGADOR

IMPORTANTE: Las pistolas pulverizadoras, excepto el Modelo DH3200, vienen de fábrica listas para funcionar sin-purgador. El modelo DH3200 no es convertible.

MODELOS DH3800/DH4200

(Vea la Figura 5)

1.Desconéctele la perilla de control de fluído, el resorte grande y la aguja de fluído.

2.Desconéctele y guarde el resorte pequeño o guárdelo dentro del resorte grande.

3.Para ensamblar la unidad, haga lo contrario a lo indicado en el paso 1.

Aguja de Fluído | |

Resorte | |

Pequeño | |

| Perilla de |

Resorte Grande | Control de |

Fluído |

Figura 5 | |

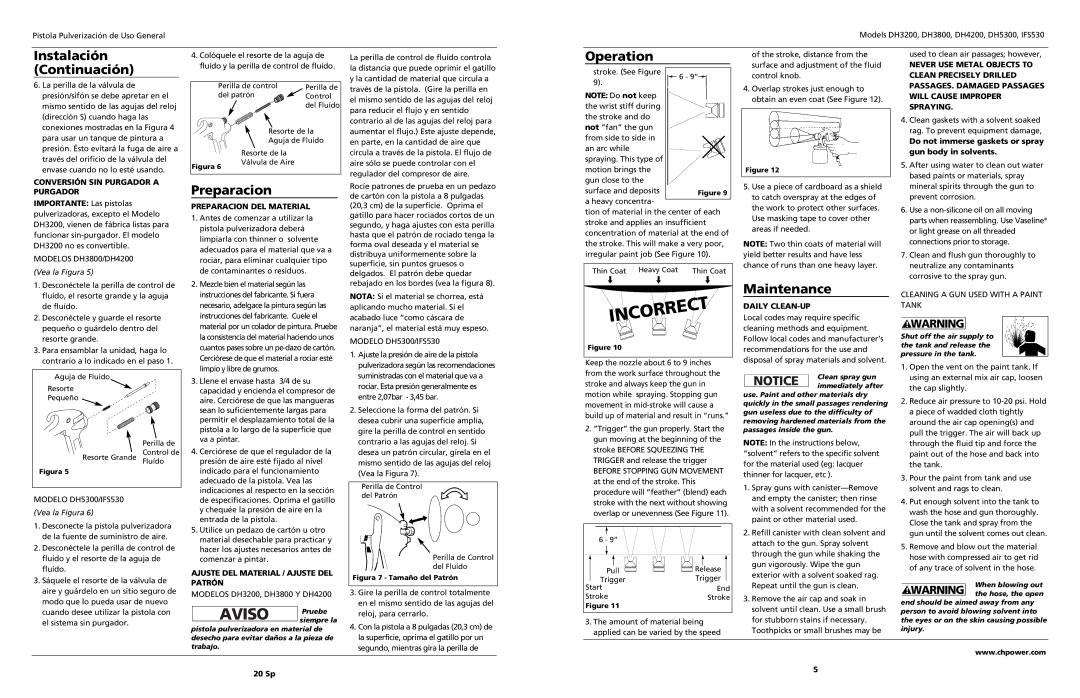

MODELO DH5300/IFS530

(Vea la Figura 6)

1.Desconecte la pistola pulverizadora de la fuente de suministro de aire.

2.Desconéctele la perilla de control de fluído y el resorte de la aguja de fluído.

3.Sáquele el resorte de la válvula de aire y guárdelo en un sitio seguro de modo que lo pueda usar de nuevo cuando desee utilizar la pistola con el sistema sin purgador.

4.Colóquele el resorte de la aguja de fluído y la perilla de control de fluído.

Perilla de control | Perilla de |

del patrón | Control |

| | del Fluído |

| Resorte de la |

| Aguja de Fluído |

| Resorte de la | |

Figura 6 | Válvula de Aire | |

| |

Preparacion

PREPARACION DEL MATERIAL

1.Antes de comenzar a utilizar la pistola pulverizadora deberá limpiarla con thinner o solvente adecuados para el material que va a rociar, para eliminar cualquier tipo de contaminantes o residuos.

2.Mezcle bien el material según las instrucciones del fabricante. Si fuera necesario, adelgace la pintura según las instrucciones del fabricante. Cuele el material por un colador de pintura. Pruebe la consistencia del material haciendo unos cuantos pases sobre un pe-dazo de cartón. Cerciórese de que el material a rociar esté limpio y libre de grumos.

3.Llene el envase hasta 3/4 de su capacidad y encienda el compresor de aire. Cerciórese de que las mangueras sean lo suficientemente largas para permitir el desplazamiento total de la pistola a lo largo de la superficie que va a pintar.

4.Cerciórese de que el regulador de la presión de aire esté fijado al nivel indicado para el funcionamiento adecuado de la pistola. Vea las indicaciones al respecto en la sección de especificaciones. Oprima el gatillo y chequée la presión de aire en la entrada de la pistola.

5.Utilice un pedazo de cartón u otro material desechable para practicar y hacer los ajustes necesarios antes de comenzar a pintar.

AJUSTE DEL MATERIAL / AJUSTE DEL PATRÓN

MODELOS DH3200, DH3800 Y DH4200

AVISO Pruebe siempre la

pistola pulverizadora en material de desecho para evitar daños a la pieza de trabajo.

La perilla de control de fluído controla la distancia que puede oprimir el gatillo y la cantidad de material que circula a través de la pistola. (Gire la perilla en el mismo sentido de las agujas del reloj para reducir el flujo y en sentido contrario al de las agujas del reloj para aumentar el flujo.) Este ajuste depende, en parte, en la cantidad de aire que circula a través de la pistola. El flujo de aire sólo se puede controlar con el regulador del compresor de aire.

Rocíe patrones de prueba en un pedazo de cartón con la pistola a 8 pulgadas (20,3 cm) de la superficie. Oprima el gatillo para hacer rociados cortos de un segundo, y haga ajustes con esta perilla hasta que el patrón de rociado tenga la forma oval deseada y el material se distribuya uniformemente sobre la superficie, sin puntos gruesos o delgados. El patrón debe quedar rebajado en los bordes (vea la figura 8).

NOTA: Si el material se chorrea, está aplicando mucho material. Si el acabado luce “como cáscara de naranja”, el material está muy espeso.

MODELO DH5300/IFS530

1.Ajuste la presión de aire de la pistola pulverizadora según las recomendaciones suministradas con el material que va a rociar. Esta presión generalmente es entre 2,07bar - 3,45 bar.

2.Seleccione la forma del patrón. Si desea cubrir una superficie amplia, gire la perilla de control en sentido contrario a las agujas del reloj. Si desea un patrón circular, gírela en el mismo sentido de las agujas del reloj (Vea la Figura 7).

Perilla de Control del Patrón

Perilla de Control del Fluído

Figura 7 - Tamaño del Patrón

3. Gire la perilla de control totalmente |

en el mismo sentido de las agujas del |

reloj, para cerrarlo. |

4. Con la pistola a 8 pulgadas (20,3 cm) de |

la superficie, oprima el gatillo por un |

segundo, mientras gira la perilla de |

Operation

stroke. (See Figure | | | | | | | | | | |

| | 6 - 9” | | | | | | |

9). | | | | | | | | | | |

NOTE: Do not keep | | | | | | | | | | |

| | | | | | | | | |

the wrist stiff during | | | | | | | | | | |

| | | | | | | | |

the stroke and do | | | | | | | | | | |

| | | | | | | | |

not “fan” the gun | | | | | | | | | | |

from side to side in | | | | | | | | | | |

an arc while | | | | | | | | | | |

spraying. This type of | | | | | | | | | | |

motion brings the | | | | | | | | | | |

gun close to the | | | | | | | | | | |

surface and deposits | | | | Figure 9 |

a heavy concentra- | | | | | | | | | | |

| | | | | | | | | |

tion of material in the center of each stroke and applies an insufficient concentration of material at the end of the stroke. This will make a very poor, irregular paint job (See Figure 10).

Thin Coat Heavy Coat | Thin Coat |

Figure 10

Keep the nozzle about 6 to 9 inches from the work surface throughout the stroke and always keep the gun in motion while spraying. Stopping gun movement in mid-stroke will cause a build up of material and result in “runs.”

2.“Trigger” the gun properly. Start the gun moving at the beginning of the stroke BEFORE SQUEEZING THE TRIGGER and release the trigger

BEFORE STOPPING GUN MOVEMENT at the end of the stroke. This procedure will “feather” (blend) each stroke with the next without showing overlap or unevenness (See Figure 11).

6 - 9” | |

Pull | Release |

Trigger | Trigger |

Start | End |

Stroke | Stroke |

Figure 11 | |

3.The amount of material being applied can be varied by the speed

of the stroke, distance from the surface and adjustment of the fluid control knob.

4.Overlap strokes just enough to obtain an even coat (See Figure 12).

Figure 12

5.Use a piece of cardboard as a shield to catch overspray at the edges of the work to protect other surfaces. Use masking tape to cover other areas if needed.

NOTE: Two thin coats of material will yield better results and have less chance of runs than one heavy layer.

Maintenance

DAILY CLEAN-UP

Local codes may require specific cleaning methods and equipment. Follow local codes and manufacturer’s recommendations for the use and disposal of spray materials and solvent.

| NOTICE | Clean spray gun |

| immediately after |

| |

use. Paint and other materials dry quickly in the small passages rendering gun useless due to the difficulty of removing hardened materials from the passages inside the gun.

NOTE: In the instructions below, “solvent” refers to the specific solvent for the material used (eg: lacquer thinner for lacquer, etc ).

1.Spray guns with canister—Remove and empty the canister; then rinse with a solvent recommended for the paint or other material used.

2.Refill canister with clean solvent and attach to the gun. Spray solvent through the gun while shaking the gun vigorously. Wipe the gun exterior with a solvent soaked rag. Repeat until the gun is clean.

3.Remove the air cap and soak in solvent until clean. Use a small brush for stubborn stains if necessary. Toothpicks or small brushes may be

used to clean air passages; however,

NEVER USE METAL OBJECTS TO CLEAN PRECISELY DRILLED PASSAGES. DAMAGED PASSAGES WILL CAUSE IMPROPER SPRAYING.

4.Clean gaskets with a solvent soaked rag. To prevent equipment damage,

Do not immerse gaskets or spray gun body in solvents.

5.After using water to clean out water based paints or materials, spray mineral spirits through the gun to prevent corrosion.

6.Use a non-silicone oil on all moving parts when reassembling. Use Vaseline® or light grease on all threaded connections prior to storage.

7.Clean and flush gun thoroughly to neutralize any contaminants corrosive to the spray gun.

CLEANING A GUN USED WITH A PAINT TANK

!WARNING

Shut off the air supply to the tank and release the pressure in the tank.

1.Open the vent on the paint tank. If using an external mix air cap, loosen the cap slightly.

2.Reduce air pressure to 10-20 psi. Hold a piece of wadded cloth tightly around the air cap opening(s) and pull the trigger. The air will back up through the fluid tip and force the paint out of the hose and back into the tank.

3.Pour the paint from tank and use solvent and rags to clean.

4.Put enough solvent into the tank to wash the hose and gun thoroughly. Close the tank and spray from the gun until the solvent comes out clean.

5.Remove and blow out the material hose with compressed air to get rid of any trace of solvent in the hose.

When blowing out the hose, the open

end should be aimed away from any person to avoid blowing solvent into the eyes or on the skin causing possible injury.