EZ5000 Series

Troubleshooting Chart (Cont.)

Symptom

Possible Cause(s) | Corrective Action |

Poor spray pattern – tails, bursts of material, splotches in pattern

1.Material too thick or not strained.

2.Spray tip dirty, worn or defective.

3.Dirty or worn inlet or outlet valve.

4.Pressure is adjusted too low for material being sprayed.

5.Clogged suction filter.

6.Clogged gun filter.

7.Tip is too large for material being sprayed.

8.Spray tip in clean position.

1.Thin, mix and strain all materi- al.

2.Clean or replace spray tip.

3.Remove and clean or replace inlet and/or outlet valve.

4.Turn lever clockwise to increase pressure to gun.

5.Clean or replace suction filter.

6.a.Remove gun filter.

b.Check for debris in filter hous- ing.

c.If debris is found, force water through gun while filter is still removed.

d.Replace filter.

7.Replace with smaller tip size.

8.Turn spray tip to spray position.

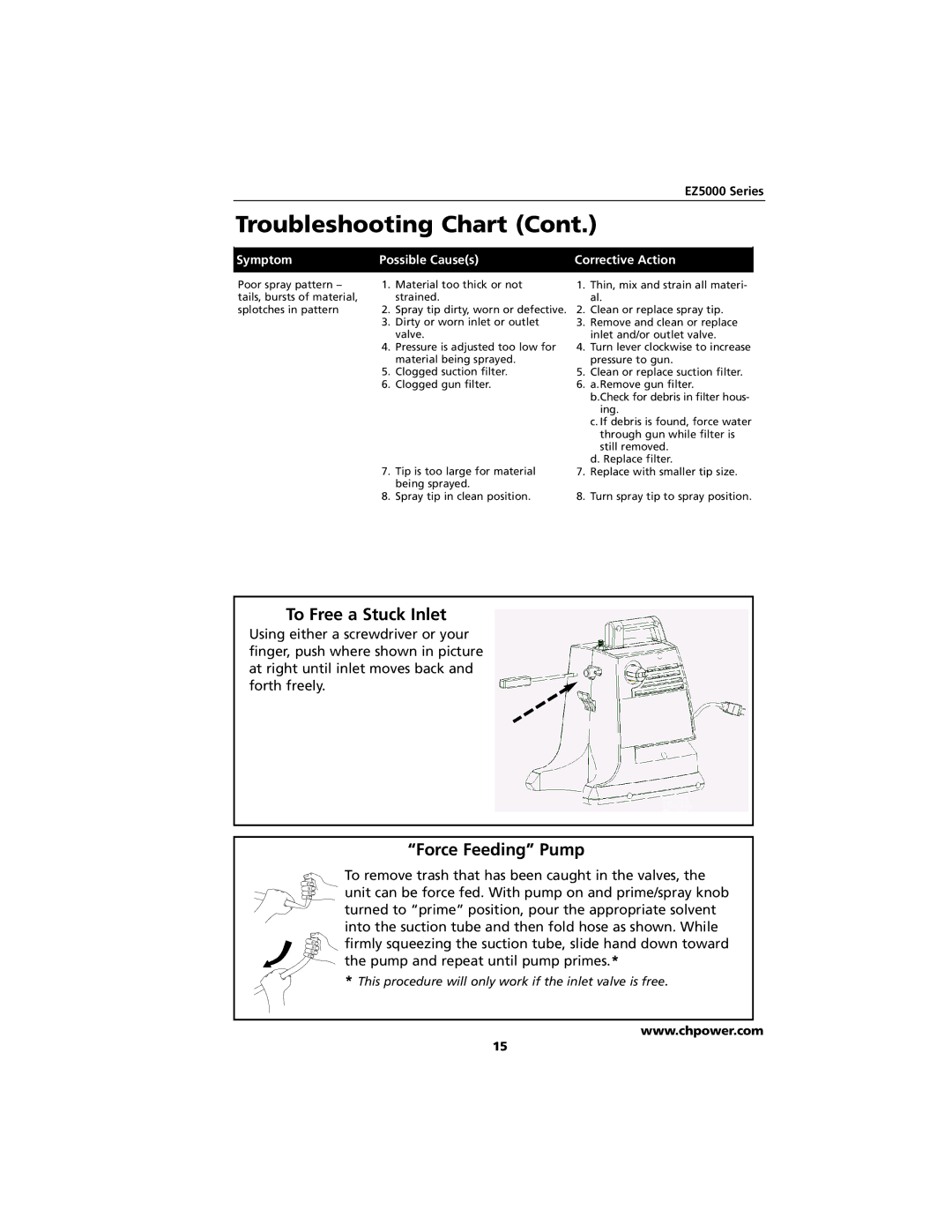

To Free a Stuck Inlet

Using either a screwdriver or your finger, push where shown in picture at right until inlet moves back and forth freely.

“Force Feeding” Pump

To remove trash that has been caught in the valves, the

unit can be force fed. With pump on and prime/spray knob turned to “prime” position, pour the appropriate solvent into the suction tube and then fold hose as shown. While

![]() firmly squeezing the suction tube, slide hand down toward

firmly squeezing the suction tube, slide hand down toward ![]() the pump and repeat until pump primes.*

the pump and repeat until pump primes.*

* This procedure will only work if the inlet valve is free.

www.chpower.com

15