WG4000

Assembly (Continued)

9.Carefully slip contact tip over wire and screw it into torch neck. Install nozzle by turning clockwise (See Figure 5). Cut wire off approximately 1/4” from end of nozzle.

Contact Tip Markings

| Wire Size |

| mm | |

|

|

|

|

|

| .024” | or | .6 |

|

|

|

|

|

|

| .030” | or | .8 |

|

|

|

|

|

|

| .035” | or | .9 |

|

|

|

|

|

|

| .040” | or | 1.0 |

|

|

|

|

|

|

|

|

|

|

|

POLARITY

Polarity must be set to match the type of welding process you wish to use. MIG wire welding with bottled shielding gas uses DCEP (DC electrode positive).

The WG4000 features

Both leads have spade ends with holes to go over the polarity posts. Turn the polarity knob counterclockwise to remove. Slip the end of the appropriate lead over the post. Then replace the polarity knob on the post and tighten securely, turning clockwise.

These connections must be tight to prevent overheating.

| Torch | Work |

Mig | + | — |

Flux | — | + |

Work Cable |

|

|

|

| Torch |

Figure 6 |

| Cable |

DUTY CYCLE / THERMOSTATIC PROTECTION

Welder duty cycle is the percentage of actual weld time that can occur in a ten minute interval. For example, at a 10% duty cycle, actual welding can occur for

one minute. Then the welder must cool for nine minutes.

Internal components of this welder are protected from overheating with an automatic thermal switch. A yellow lamp is illuminated on the front panel if the duty cycle is exceeded. Welding operations may continue when the yellow lamp is no longer illuminated.

Welding Helmet Assembly

(PROMOTIONAL MODELS ONLY)

MODEL WT1000

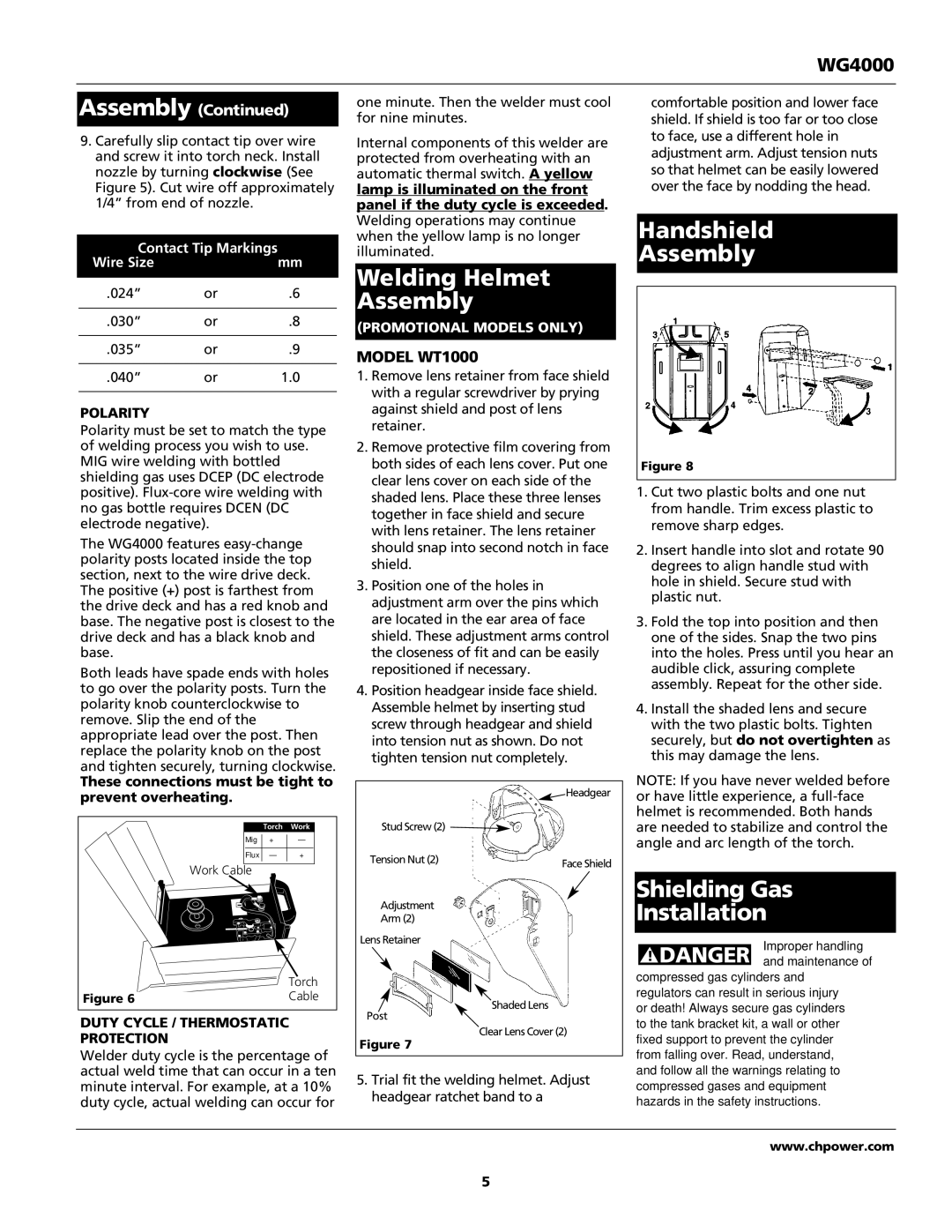

1.Remove lens retainer from face shield with a regular screwdriver by prying against shield and post of lens retainer.

2.Remove protective film covering from both sides of each lens cover. Put one clear lens cover on each side of the shaded lens. Place these three lenses together in face shield and secure with lens retainer. The lens retainer should snap into second notch in face shield.

3.Position one of the holes in adjustment arm over the pins which are located in the ear area of face shield. These adjustment arms control the closeness of fit and can be easily repositioned if necessary.

4.Position headgear inside face shield. Assemble helmet by inserting stud screw through headgear and shield into tension nut as shown. Do not tighten tension nut completely.

![]() Headgear

Headgear

Stud Screw (2) ![]()

Tension Nut (2) | Face Shield |

|

Adjustment

Arm (2)

Lens Retainer

Shaded Lens

Post

Clear Lens Cover (2)

Figure 7

5.Trial fit the welding helmet. Adjust headgear ratchet band to a

comfortable position and lower face shield. If shield is too far or too close to face, use a different hole in adjustment arm. Adjust tension nuts so that helmet can be easily lowered over the face by nodding the head.

Handshield

Assembly

Figure 8

1.Cut two plastic bolts and one nut from handle. Trim excess plastic to remove sharp edges.

2.Insert handle into slot and rotate 90 degrees to align handle stud with hole in shield. Secure stud with plastic nut.

3.Fold the top into position and then one of the sides. Snap the two pins into the holes. Press until you hear an audible click, assuring complete assembly. Repeat for the other side.

4.Install the shaded lens and secure with the two plastic bolts. Tighten securely, but do not overtighten as this may damage the lens.

NOTE: If you have never welded before or have little experience, a

Shielding Gas

Installation

Improper handling and maintenance of

compressed gas cylinders and regulators can result in serious injury or death! Always secure gas cylinders to the tank bracket kit, a wall or other fixed support to prevent the cylinder from falling over. Read, understand, and follow all the warnings relating to compressed gases and equipment hazards in the safety instructions.

www.chpower.com

5