WG4000

Welding Guidelines (Continued)

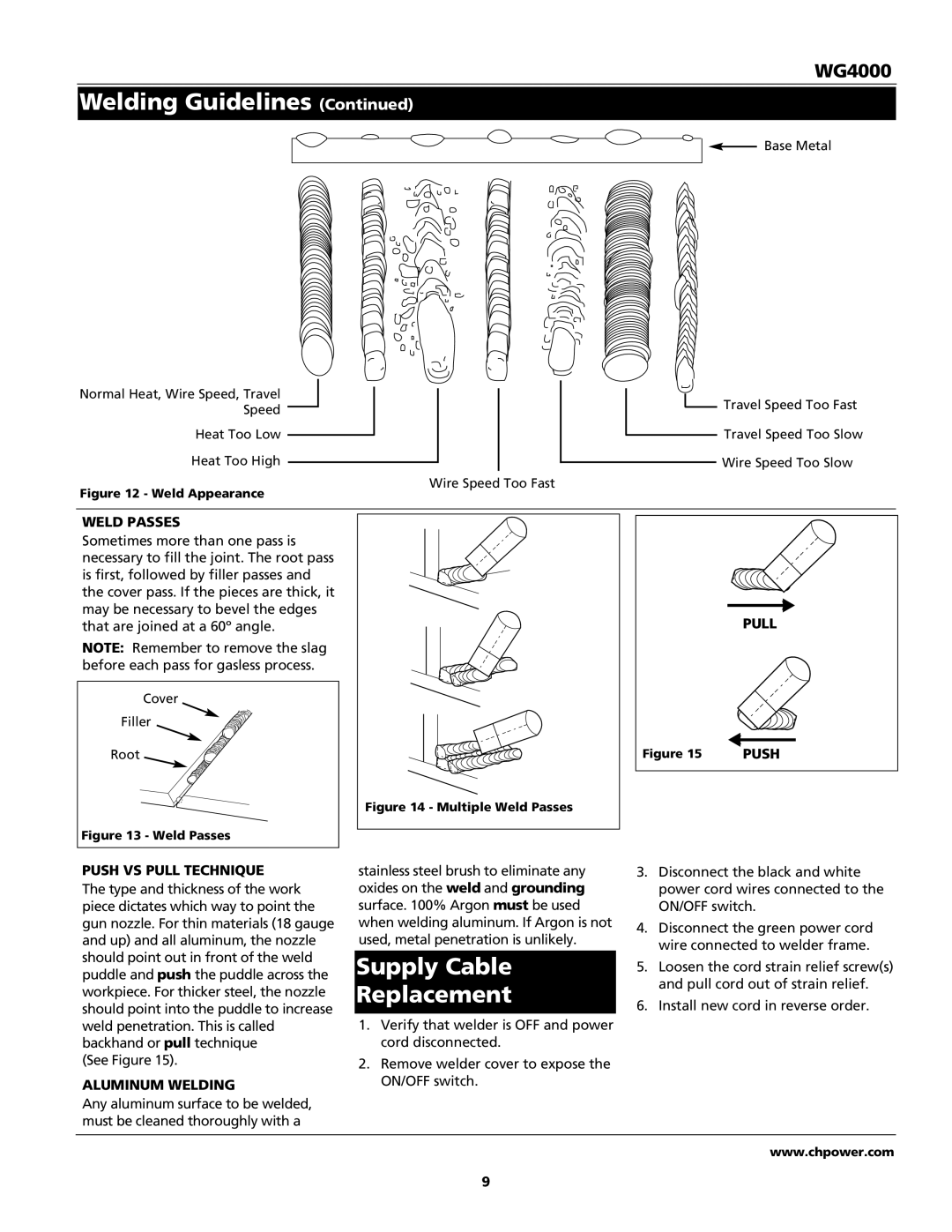

Normal Heat, Wire Speed, Travel Speed

Heat Too Low

Heat Too High

Figure 12 - Weld Appearance

Base Metal

Travel Speed Too Fast

Travel Speed Too Slow

Wire Speed Too Slow

Wire Speed Too Fast

WELD PASSES

Sometimes more than one pass is necessary to fill the joint. The root pass is first, followed by filler passes and the cover pass. If the pieces are thick, it may be necessary to bevel the edges that are joined at a 60º angle.

NOTE: Remember to remove the slag before each pass for gasless process.

Cover

Filler

Root

PULL

Figure 15 | PUSH |

Figure 14 - Multiple Weld Passes

Figure 13 - Weld Passes

PUSH VS PULL TECHNIQUE

The type and thickness of the work piece dictates which way to point the gun nozzle. For thin materials (18 gauge and up) and all aluminum, the nozzle should point out in front of the weld puddle and push the puddle across the workpiece. For thicker steel, the nozzle should point into the puddle to increase weld penetration. This is called backhand or pull technique

(See Figure 15).

ALUMINUM WELDING

Any aluminum surface to be welded, must be cleaned thoroughly with a

stainless steel brush to eliminate any oxides on the weld and grounding surface. 100% Argon must be used when welding aluminum. If Argon is not used, metal penetration is unlikely.

Supply Cable

Replacement

1.Verify that welder is OFF and power cord disconnected.

2.Remove welder cover to expose the ON/OFF switch.

3.Disconnect the black and white power cord wires connected to the ON/OFF switch.

4.Disconnect the green power cord wire connected to welder frame.

5.Loosen the cord strain relief screw(s) and pull cord out of strain relief.

6.Install new cord in reverse order.

www.chpower.com

9