Wire Feed Arc Welder |

|

|

|

| ||

Cylinder |

|

|

| NOTE: Before installing welding wire, | ||

|

|

| be sure that its diameter matches the | |||

chain |

|

|

| |||

|

|

| diameter of the groove in the drive | |||

|

|

|

| roller on the wire feed mechanism and | ||

Cylinder |

|

|

| that the wire matches the contact tip in | ||

bracket |

|

|

| the end of the gun. Any mismatch | ||

|

|

| could cause the wire to slip or bind. | |||

|

|

|

| |||

|

|

|

| 1. Verify that welder is off. Open panel | ||

Nut |

|

|

| on welder to expose wire feed | ||

|

|

|

| mechanism. |

| |

Washer |

|

| 2. Remove spool lock by pushing in and | |||

|

|

|

| rotating it a 1/4 turn counterclockwise. | ||

|

|

|

| The knob, spring, and spool spacer can | ||

|

|

|

| now be removed. (See Figure 4). | ||

|

|

|

| NOTE: Spool spacer and spindle spacer | ||

|

|

|

| act as an 8” spool adapter. Purchase of | ||

| Axle |

|

| an adapter is not necessary. | ||

| Bolt |

|

| 3. Loosen wire feed tensioning screw | ||

Plastic |

|

| on drive mechanism. This allows | |||

Wheel |

|

| initial feeding of wire into gun liner | |||

hub |

| Foot | ||||

| Bolt | by hand. |

| |||

|

| assembly | 4. Place wire spool on spindle so that | |||

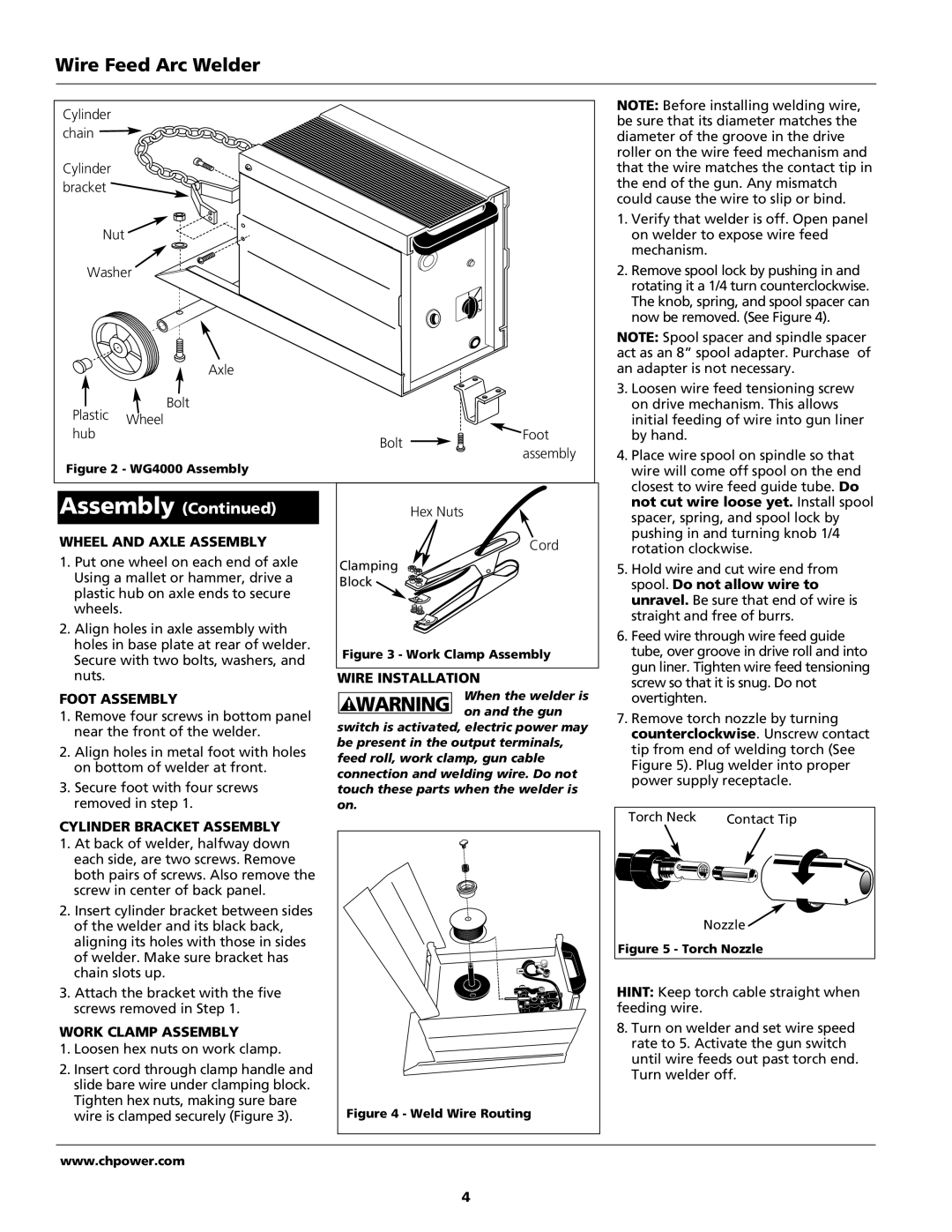

Figure 2 - WG4000 Assembly |

| |||||

|

| wire will come off spool on the end | ||||

Assembly (Continued) |

|

| closest to wire feed guide tube. Do | |||

Hex Nuts | not cut wire loose yet. Install spool | |||||

spacer, spring, and spool lock by | ||||||

|

|

|

| |||

WHEEL AND AXLE ASSEMBLY |

| Cord | pushing in and turning knob 1/4 | |||

| rotation clockwise. | |||||

1. Put one wheel on each end of axle | Clamping |

| 5. Hold wire and cut wire end from | |||

Using a mallet or hammer, drive a |

| |||||

Block |

| spool. Do not allow wire to | ||||

plastic hub on axle ends to secure |

| |||||

|

| unravel. Be sure that end of wire is | ||||

wheels. |

|

|

| |||

|

|

| straight and free of burrs. | |||

2. Align holes in axle assembly with |

|

| ||||

|

| 6. Feed wire through wire feed guide | ||||

holes in base plate at rear of welder. |

|

| ||||

Figure 3 - Work Clamp Assembly | tube, over groove in drive roll and into | |||||

Secure with two bolts, washers, and | ||||||

|

| gun liner. Tighten wire feed tensioning | ||||

nuts. |

| WIRE INSTALLATION | ||||

| screw so that it is snug. Do not | |||||

|

|

| When the welder is | |||

FOOT ASSEMBLY | ! WARNING | overtighten. |

| |||

1. Remove four screws in bottom panel | on and the gun | 7. Remove torch nozzle by turning | ||||

switch is activated, electric power may | ||||||

near the front of the welder. | counterclockwise. Unscrew contact | |||||

be present in the output terminals, | ||||||

2. Align holes in metal foot with holes | tip from end of welding torch (See | |||||

feed roll, work clamp, gun cable | ||||||

on bottom of welder at front. | Figure 5). Plug welder into proper | |||||

connection and welding wire. Do not | ||||||

3. Secure foot with four screws | power supply receptacle. | |||||

touch these parts when the welder is | ||||||

|

| |||||

removed in step 1. | on. |

| Torch Neck | Contact Tip | ||

CYLINDER BRACKET ASSEMBLY |

|

| ||||

|

|

|

| |||

1. At back of welder, halfway down |

|

|

|

| ||

each side, are two screws. Remove |

|

|

|

| ||

both pairs of screws. Also remove the |

|

|

|

| ||

screw in center of back panel. |

|

|

|

| ||

2. Insert cylinder bracket between sides |

|

| Nozzle | |||

of the welder and its black back, |

|

| ||||

aligning its holes with those in sides |

|

| Figure 5 - Torch Nozzle | |||

of welder. Make sure bracket has |

|

| ||||

|

|

|

| |||

chain slots up. |

|

|

|

| ||

3. Attach the bracket with the five |

|

| HINT: Keep torch cable straight when | |||

screws removed in Step 1. |

|

| feeding wire. |

| ||

WORK CLAMP ASSEMBLY |

|

| 8. Turn on welder and set wire speed | |||

1. Loosen hex nuts on work clamp. |

|

| rate to 5. Activate the gun switch | |||

|

| until wire feeds out past torch end. | ||||

2. Insert cord through clamp handle and |

|

| ||||

|

| Turn welder off. | ||||

slide bare wire under clamping block. |

|

| ||||

|

|

|

| |||

Tighten hex nuts, making sure bare | Figure 4 - Weld Wire Routing |

|

| |||

wire is clamped securely (Figure 3). |

|

| ||||

www.chpower.com |

|

|

|

| ||

|

|

| 4 |

|

| |