Model WS2100

positions and weld joints become necessary, electrode angle becomes an increasingly important factor in obtaining a satisfactory weld. Electrode angle involves two positions - travel angle and work angle. (See Figure 8.)

Travel angle is the angle in the line of welding and may vary from 5º to 45º from the vertical, depending on welding conditions.

Work angle is the angle from horizontal, measured at right angles to the line of welding.

For most applications, a 45º travel angle and 45º work angle is sufficient. For specific applications, consult an arc welding handbook.

Note: Right handed welders should weld from left to right. Left handed welders should weld from right to left. The electrode should always point into the weld puddle as shown.

Arc Length

Arc length is the distance from the work piece to the tip of the electrode, the distance which the arc must travel. A proper arc length is essential to generate the heat needed for welding (See Fig. 11). An arc that is too long produces an unstable arc, reduces penetration, increases spatter, and

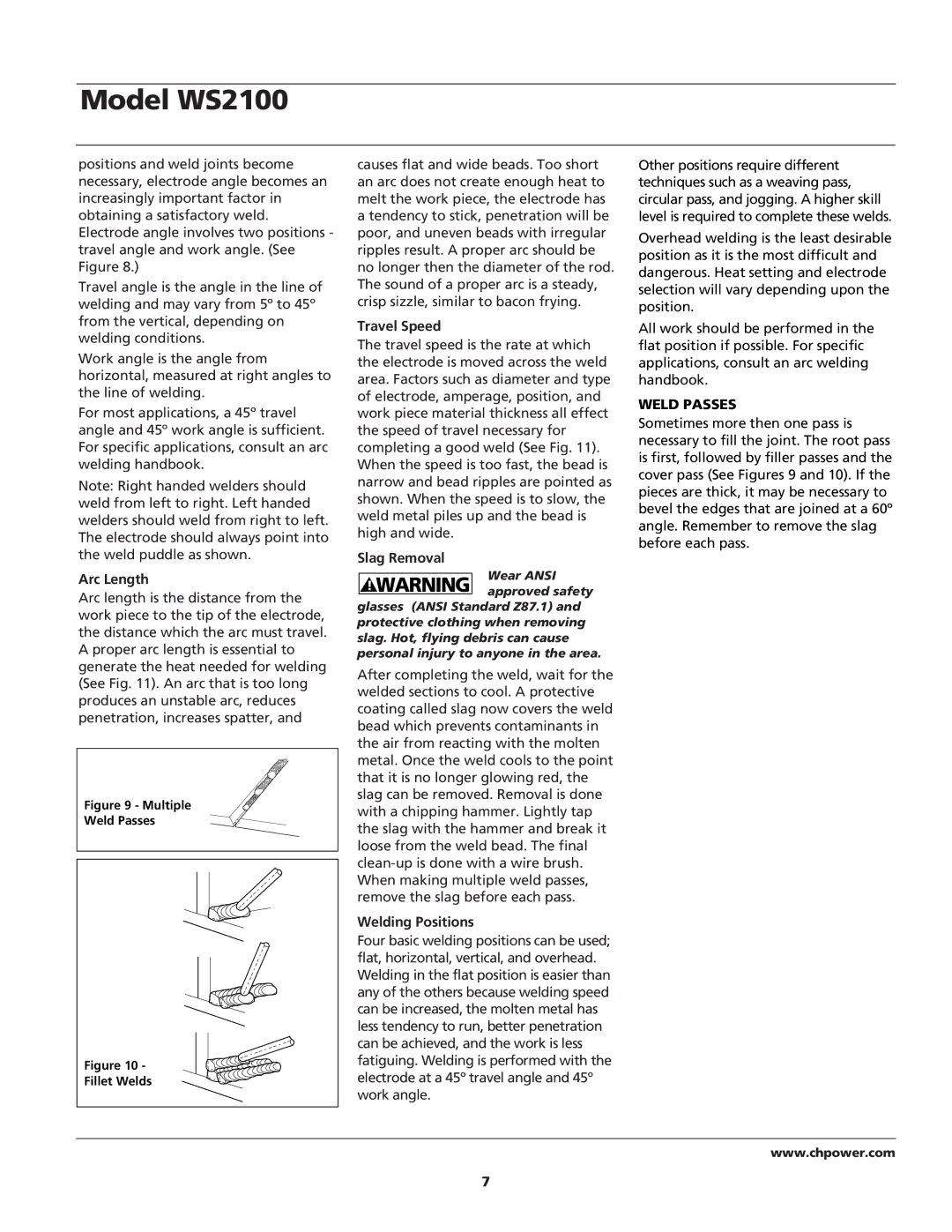

Figure 9 - Multiple

Weld Passes

Figure 10 -

Fillet Welds

causes flat and wide beads. Too short an arc does not create enough heat to melt the work piece, the electrode has a tendency to stick, penetration will be poor, and uneven beads with irregular ripples result. A proper arc should be no longer then the diameter of the rod. The sound of a proper arc is a steady, crisp sizzle, similar to bacon frying.

Travel Speed

The travel speed is the rate at which the electrode is moved across the weld area. Factors such as diameter and type of electrode, amperage, position, and work piece material thickness all effect the speed of travel necessary for completing a good weld (See Fig. 11). When the speed is too fast, the bead is narrow and bead ripples are pointed as shown. When the speed is to slow, the weld metal piles up and the bead is high and wide.

Slag Removal

Wear ANSI approved safety

glasses (ANSI Standard Z87.1) and protective clothing when removing slag. Hot, flying debris can cause personal injury to anyone in the area.

After completing the weld, wait for the welded sections to cool. A protective coating called slag now covers the weld bead which prevents contaminants in the air from reacting with the molten metal. Once the weld cools to the point that it is no longer glowing red, the slag can be removed. Removal is done with a chipping hammer. Lightly tap the slag with the hammer and break it loose from the weld bead. The final

Welding Positions

Four basic welding positions can be used; flat, horizontal, vertical, and overhead. Welding in the flat position is easier than any of the others because welding speed can be increased, the molten metal has less tendency to run, better penetration can be achieved, and the work is less fatiguing. Welding is performed with the electrode at a 45º travel angle and 45º work angle.

Other positions require different techniques such as a weaving pass, circular pass, and jogging. A higher skill level is required to complete these welds.

Overhead welding is the least desirable position as it is the most difficult and dangerous. Heat setting and electrode selection will vary depending upon the position.

All work should be performed in the flat position if possible. For specific applications, consult an arc welding handbook.

WELD PASSES

Sometimes more then one pass is necessary to fill the joint. The root pass is first, followed by filler passes and the cover pass (See Figures 9 and 10). If the pieces are thick, it may be necessary to bevel the edges that are joined at a 60º angle. Remember to remove the slag before each pass.

www.chpower.com

7