Model WS2100

protection with proper shade, flame resistant clothing, leather welding gloves, and full foot protection.

If heating, welding, or cutting

materials that are galvanized, zinc plated, lead, or cadmium plated refer to the General Safety Information Section for instructions. Extremely toxic fumes are created when these metals are heated.

4.Connect the ground clamp to the work piece or workbench (if metal). Make sure the contact is secure, and not obstructed by paint, varnish, corrosion, or

5.Insert the exposed part of the electrode (the end with no flux) into the jaws of the electrode holder.

6.Set the amperage adjustment knob to the proper amperage for the electrode diameter. Refer to the following chart for proper electrode current settings.

Amperage Output Guide

Current Setting

30-60 Amps

The electrode holder and rod are

electrically "hot"(have current potential) when the welder is on. Grounding against any metallic surface may produce an arc which could cause sparks and damage eyesight.

7.Hold the electrode and holder away from the grounded work piece or workbench. Turn on the welder. A green light is illuminated when the welder power is on.

8.Position the electrode to begin weld, lower the welding helmet or position the hand shield, and strike an arc.

Adjust weld amperage as needed.

9.When finished welding, turn welder off and store properly.

Duty Cycle / Thermostatic Protection

Welder duty cycle is the percentage of

actual weld time that can occur in a ten minute interval. For example, at a 10% duty cycle, actual welding can occur for one minute, then the welder must cool for nine minutes.

Internal components of this welder are protected from overheating with an automatic thermal switch. A yellow lamp is illuminated on the control panel if the duty cycle is exceeded. Welding operations may continue when the yellow lamp is no longer illuminated.

Maintenance

| Disconnect power | |

! WARNING | ||

supply and turn | ||

|

machine off before inspecting or servicing any components.

Before every use:

1.Check condition of weld cables and immediately repair or replace any cables with damaged insulation.

2.Check condition of power cord and immediately repair or replace any cord if damaged.

3.Check condition of electrode holder insulating pieces and immediately replace cracked or missing insulators. Verify that all fasteners are tight and insulated.

|

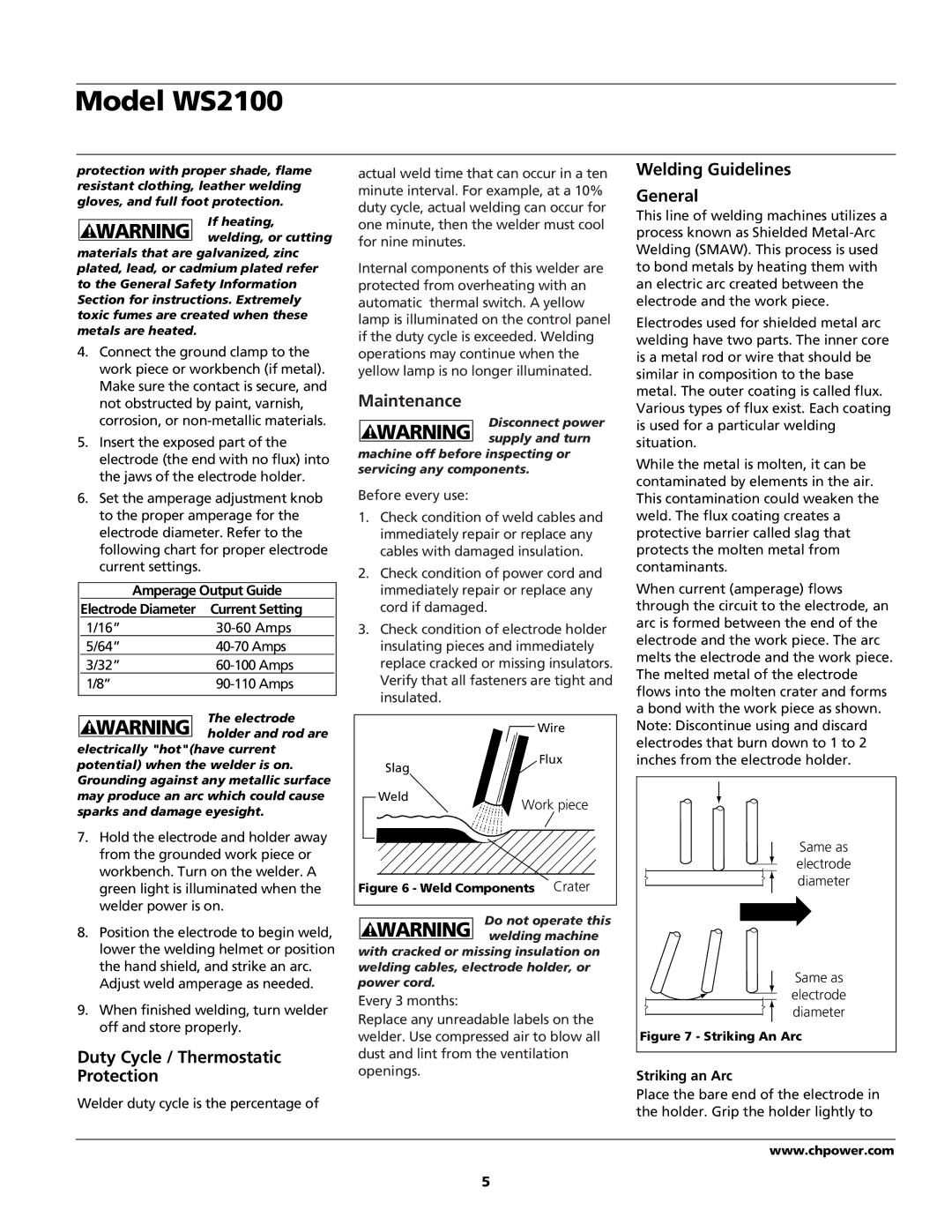

| Wire |

Slag |

| Flux |

|

| |

Weld | Work piece | |

| ||

Figure 6 | - Weld Components | Crater |

Do not operate this welding machine

with cracked or missing insulation on welding cables, electrode holder, or power cord.

Every 3 months:

Replace any unreadable labels on the welder. Use compressed air to blow all dust and lint from the ventilation openings.

Welding Guidelines

General

This line of welding machines utilizes a process known as Shielded

Electrodes used for shielded metal arc welding have two parts. The inner core is a metal rod or wire that should be similar in composition to the base metal. The outer coating is called flux. Various types of flux exist. Each coating is used for a particular welding situation.

While the metal is molten, it can be contaminated by elements in the air. This contamination could weaken the weld. The flux coating creates a protective barrier called slag that protects the molten metal from contaminants.

When current (amperage) flows through the circuit to the electrode, an arc is formed between the end of the electrode and the work piece. The arc melts the electrode and the work piece. The melted metal of the electrode flows into the molten crater and forms a bond with the work piece as shown. Note: Discontinue using and discard electrodes that burn down to 1 to 2 inches from the electrode holder.

Same as

electrode diameter

Same as

electrode diameter

Figure 7 - Striking An Arc

Striking an Arc

Place the bare end of the electrode in the holder. Grip the holder lightly to

www.chpower.com

5