Operating Instructions and Parts Manual

Inverter Technology Arc Welder

Protection Association, Batterymarch Park, Quincy, MA 02269

Safe Handling of Compressed Gases in Cylinders

CGA Pamphlet

Code for Safety in Welding and Cutting

CSA Standard W117.2, from Canadian Standards Association, Standards Sales, 178 Rexdale Boulevard, Rexdale, Ontario, Canada M9W 1R3

Cutting And Welding Processes

NFPA Standard 51B, from National Fire Protection Association, Batterymarch Park, Quincy, MA 02269

Safe Practices For Occupational And Educational Eye And Face Protection

ANSI Standard Z87.1, from American National Standards Institute, 1430 Broadway, New York, NY 10018

Refer to the Material Safety Data Sheets and the manufacturers instructions for metals, electrodes, coatings and cleaners.

Installation

LOCATION

Selecting the proper location can significantly increase performance, reliability and life of the arc welder.

●For best results locate the welder in an environment that is clean and dry. Avoid locations exposed to high temperature, high humidity, dust and corrosive fumes. High humidity causes moisture condensation on electrical components. Moisture can contribute to corrosion and short electrical components. Dust and dirt in the welder retain moisture and increase wear of moving parts.

●Place the welder in an area that provides at least twelve inches (305 mm.) of ventilation space at both the front and rear of the unit. Keep all obstructions away from this ventilation space.

●Store electrodes in a clean, dry location with low humidity, such as

WT2240 Electrode Container, to preserve the flux coating.

●The welder control panel contains information regarding proper input voltage and amperage. Follow the specifications on the welder front panel.

●The receptacle used for the welder must be properly grounded and the welder must be the only load on the power supply circuit. Refer to the Circuit Amps chart under Specifications for correct circuit capacity.

Lens

Lens

Retainer

![]() Retainer

Retainer

Stiffener

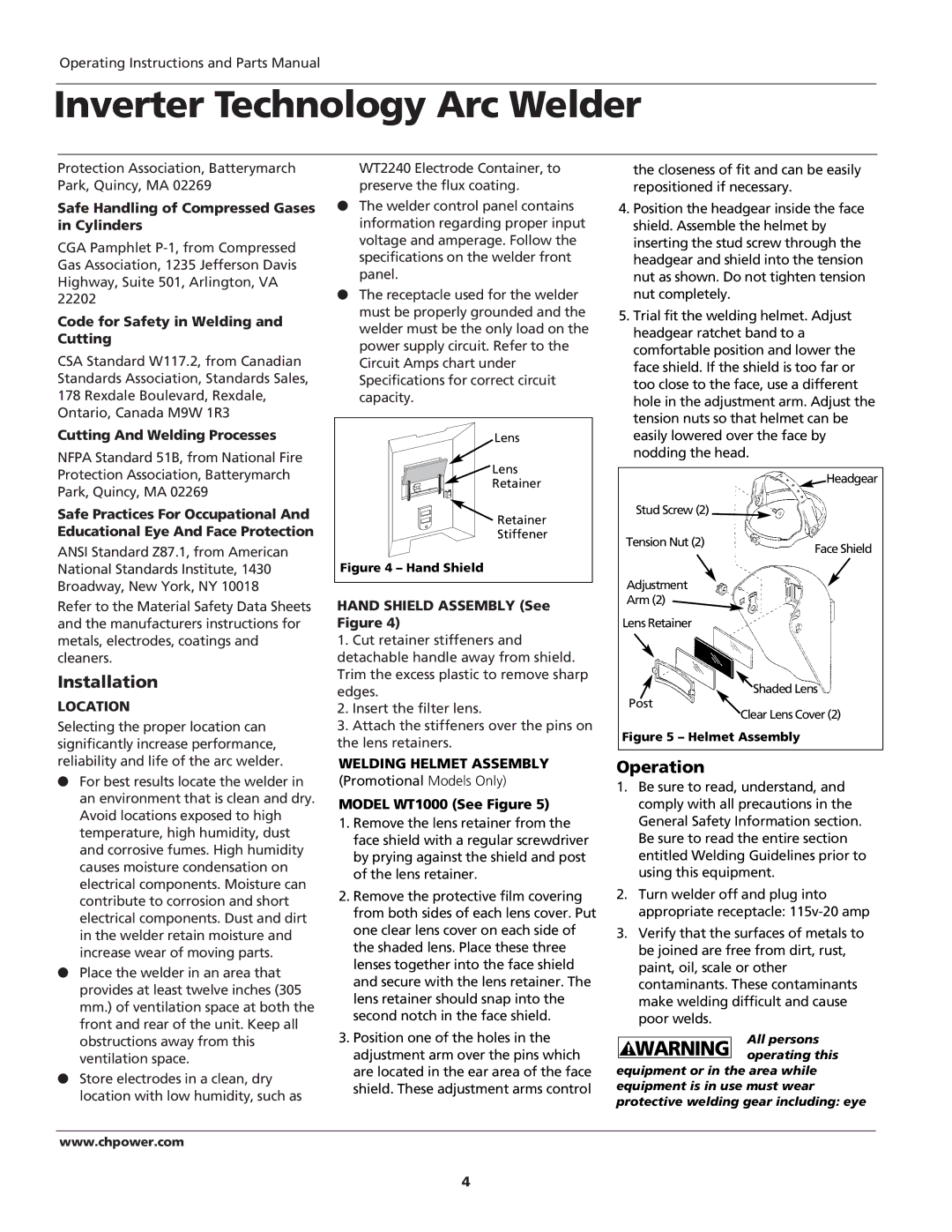

Figure 4 – Hand Shield

HAND SHIELD ASSEMBLY (See Figure 4)

1.Cut retainer stiffeners and detachable handle away from shield. Trim the excess plastic to remove sharp edges.

2.Insert the filter lens.

3.Attach the stiffeners over the pins on the lens retainers.

WELDING HELMET ASSEMBLY

(Promotional Models Only)

MODEL WT1000 (See Figure 5)

1.Remove the lens retainer from the face shield with a regular screwdriver by prying against the shield and post of the lens retainer.

2.Remove the protective film covering from both sides of each lens cover. Put one clear lens cover on each side of the shaded lens. Place these three lenses together into the face shield and secure with the lens retainer. The lens retainer should snap into the second notch in the face shield.

3.Position one of the holes in the adjustment arm over the pins which are located in the ear area of the face shield. These adjustment arms control

the closeness of fit and can be easily repositioned if necessary.

4.Position the headgear inside the face shield. Assemble the helmet by inserting the stud screw through the headgear and shield into the tension nut as shown. Do not tighten tension nut completely.

5.Trial fit the welding helmet. Adjust headgear ratchet band to a comfortable position and lower the face shield. If the shield is too far or too close to the face, use a different hole in the adjustment arm. Adjust the tension nuts so that helmet can be easily lowered over the face by nodding the head.

![]() Headgear

Headgear

Stud Screw (2)

Tension Nut (2) | Face Shield |

|

Adjustment

Arm (2)

Lens Retainer

Shaded Lens

Post

Clear Lens Cover (2)

Figure 5 – Helmet Assembly

Operation

1.Be sure to read, understand, and comply with all precautions in the General Safety Information section. Be sure to read the entire section entitled Welding Guidelines prior to using this equipment.

2.Turn welder off and plug into appropriate receptacle:

3.Verify that the surfaces of metals to be joined are free from dirt, rust, paint, oil, scale or other contaminants. These contaminants make welding difficult and cause poor welds.

All persons operating this

equipment or in the area while equipment is in use must wear protective welding gear including: eye

www.chpower.com

4