HANDLE ASSEMBLY (See Figure 2)

1.Fasten end caps onto handle.

2.Handle may be attached in two positions (high or low). Using the four screws and washers provided, attach the handle to the back of the case

WHEEL ASSEMBLY (See Figure 2)

1.Slide the axle through the holes in the sides of the case.

2.Slide the wheels onto the axle and lightly tap the pal-nuts into place on the axle grooves.

CASTER ASSEMBLY (See Figure 2)

1.Using the eight screws and washers provided, attach the casters to the bottom of the case.

Figure 2 – Handle, Wheel and Caster

Assembly

DINSE PLUG ASSEMBLY (See Figure 3)

1.Strip 1/2” of insulation from the end of the welding cable opposite the crimped connectors.

2.Insert this end of the welding cable through the dinse plug boot and slide the bare wire into the copper sleeve.

3.Insert the welding cable/copper sleeve assembly into the back of the dinse plug.

4.Tighten the setscrew, securing the cable in place.

5.Slide the boot over the hex portion of the dinse plug.

6.Repeat for the other lead.

Set Screw | Wire | Boot | Welding |

| | Cable |

| Sleeve | |

| | |

| Dinse Plug | |

Figure 3 - Dinse Plug Assembly |

WORK CLAMP ASSEMBLY (See Figure 4)

1. Remove one hex nut from work

clamp.

2.Slide welding cable with ring connector through hole in work clamp.

3.Attach ring connector to work clamp with hex nut removed in step 1.

| Hex | Ring Connector | |

| Nut | Welding |

| |

| | | Cable |

Work

Clamp

Figure 4 – Work Clamp Assembly

ELECTRODE HOLDER ASSEMBLY (See Figure 5)

1.Loosen the handle setscrew in the electrode holder a few turns. Do not remove this setscrew completely.

Remove the insulated handle and slide it over the end of the welding cable with the crimped sleeve.

2.Loosen the cable setscrew in the bottom of the brass body of the electrode holder.

3.Slide the welding cable/crimped sleeve into the back of the brass body, aligning the flat side of the crimped connector with the face of the cable setscrew.

4.Tighten the cable setscrew to securely hold the welding cable/crimped sleeve.

5.Slide the insulated handle onto the electrode holder and tighten the handle setscrew. Do not overtighten this setscrew. Overtightening will damage the insulated handle.

| Crimped | Welding |

| Sleeve | Handle |

| | Cable |

Electrode | Handle | Cable | |

Setscrew | |

Holder | Setscrew | | |

Figure 5 – Electrode Holder | |

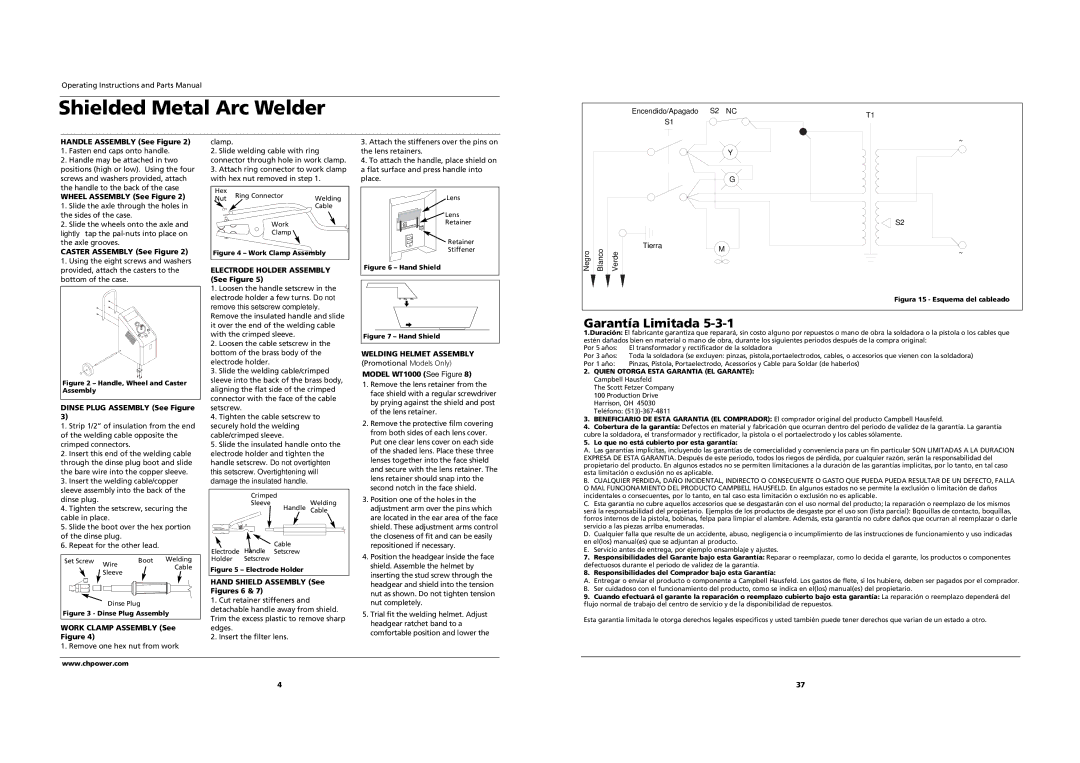

HAND SHIELD ASSEMBLY (See Figures 6 & 7)

1.Cut retainer stiffeners and detachable handle away from shield. Trim the excess plastic to remove sharp edges.

2.Insert the filter lens.

3.Attach the stiffeners over the pins on the lens retainers.

4.To attach the handle, place shield on a flat surface and press handle into place.

Lens

Lens

Retainer

Retainer

Retainer

Stiffener

Figure 6 – Hand Shield

WELDING HELMET ASSEMBLY

(Promotional Models Only)

MODEL WT1000 (See Figure 8)

1.Remove the lens retainer from the face shield with a regular screwdriver by prying against the shield and post of the lens retainer.

2.Remove the protective film covering from both sides of each lens cover. Put one clear lens cover on each side of the shaded lens. Place these three lenses together into the face shield and secure with the lens retainer. The lens retainer should snap into the second notch in the face shield.

3.Position one of the holes in the adjustment arm over the pins which are located in the ear area of the face shield. These adjustment arms control the closeness of fit and can be easily repositioned if necessary.

4.Position the headgear inside the face shield. Assemble the helmet by inserting the stud screw through the headgear and shield into the tension nut as shown. Do not tighten tension nut completely.

5.Trial fit the welding helmet. Adjust headgear ratchet band to a comfortable position and lower the

| | | | | ~ |

| | | | | Y |

| | | | | G |

| | | | | S2 |

Negro | Blanco | Verde | Tierra | M | ~ |

|

| |

| | |

| | | | | Figura 15 - Esquema del cableado |

Garantía Limitada 5-3-1

1.Duración: El fabricante garantiza que reparará, sin costo alguno por repuestos o mano de obra la soldadora o la pistola o los cables que estén dañados bien en material o mano de obra, durante los siguientes periodos después de la compra original:

Por 5 años: | El transformador y rectificador de la soldadora |

Por 3 años: | Toda la soldadora (se excluyen: pinzas, pistola,portaelectrodos, cables, o accesorios que vienen con la soldadora) |

Por 1 año: | Pinzas, Pistola, Portaelectrodo, Acessorios y Cable para Soldar (de haberlos) |

2.QUIEN OTORGA ESTA GARANTIA (EL GARANTE): Campbell Hausfeld

The Scott Fetzer Company 100 Production Drive Harrison, OH 45030 Teléfono: (513)-367-4811

3.BENEFICIARIO DE ESTA GARANTIA (EL COMPRADOR): El comprador original del producto Campbell Hausfeld.

4.Cobertura de la garantía: Defectos en material y fabricación que ocurran dentro del periodo de validez de la garantía. La garantía cubre la soldadora, el transformador y rectificador, la pistola o el portaelectrodo y los cables sólamente.

5.Lo que no está cubierto por esta garantía:

A.Las garantías implicitas, incluyendo las garantías de comercialidad y conveniencia para un fin particular SON LIMITADAS A LA DURACION EXPRESA DE ESTA GARANTIA. Después de este periodo, todos los riegos de pérdida, por cualquier razón, serán la responsabilidad del propietario del producto. En algunos estados no se permiten limitaciones a la duración de las garantías implicitas, por lo tanto, en tal caso esta limitación o exclusión no es aplicable.

B.CUALQUIER PERDIDA, DAÑO INCIDENTAL, INDIRECTO O CONSECUENTE O GASTO QUE PUEDA PUEDA RESULTAR DE UN DEFECTO, FALLA

OMAL FUNCIONAMIENTO DEL PRODUCTO CAMPBELL HAUSFELD. En algunos estados no se permite la exclusión o limitación de daños incidentales o consecuentes, por lo tanto, en tal caso esta limitación o exclusión no es aplicable.

C.Esta garantía no cubre aquellos accesorios que se desgastarán con el uso normal del producto; la reparación o reemplazo de los mismos será la responsabilidad del propietario. Ejemplos de los productos de desgaste por el uso son (lista parcial): Bqouillas de contacto, boquillas, forros internos de la pistola, bobinas, felpa para limpiar el alambre. Además, esta garantía no cubre daños que ocurran al reemplazar o darle servicio a las piezas arriba enumeradas.

D.Cualquier falla que resulte de un accidente, abuso, negligencia o incumplimiento de las instrucciones de funcionamiento y uso indicadas en el(los) manual(es) que se adjuntan al producto.

E.Servicio antes de entrega, por ejemplo ensamblaje y ajustes.

7.Responsibilidades del Garante bajo esta Garantía: Reparar o reemplazar, como lo decida el garante, los productos o componentes defectuosos durante el periodo de validez de la garantía.

8.Responsibilidades del Comprador bajo esta Garantía:

A.Entregar o enviar el producto o componente a Campbell Hausfeld. Los gastos de flete, si los hubiere, deben ser pagados por el comprador.

B.Ser cuidadoso con el funcionamiento del producto, como se indica en el(los) manual(es) del propietario.

9.Cuando efectuará el garante la reparación o reemplazo cubierto bajo esta garantía: La reparación o reemplazo dependerá del flujo normal de trabajo del centro de servicio y de la disponibilidad de repuestos.

Esta garantía limitada le otorga derechos legales especificos y usted también puede tener derechos que varian de un estado a otro.