NOTE: All dimensions are in inches.

| Liquid Chiller |

IN | OUT |

WATER INLET | WATER OUTLET |

(RETURN WATER) | (LEAVING WATER) |

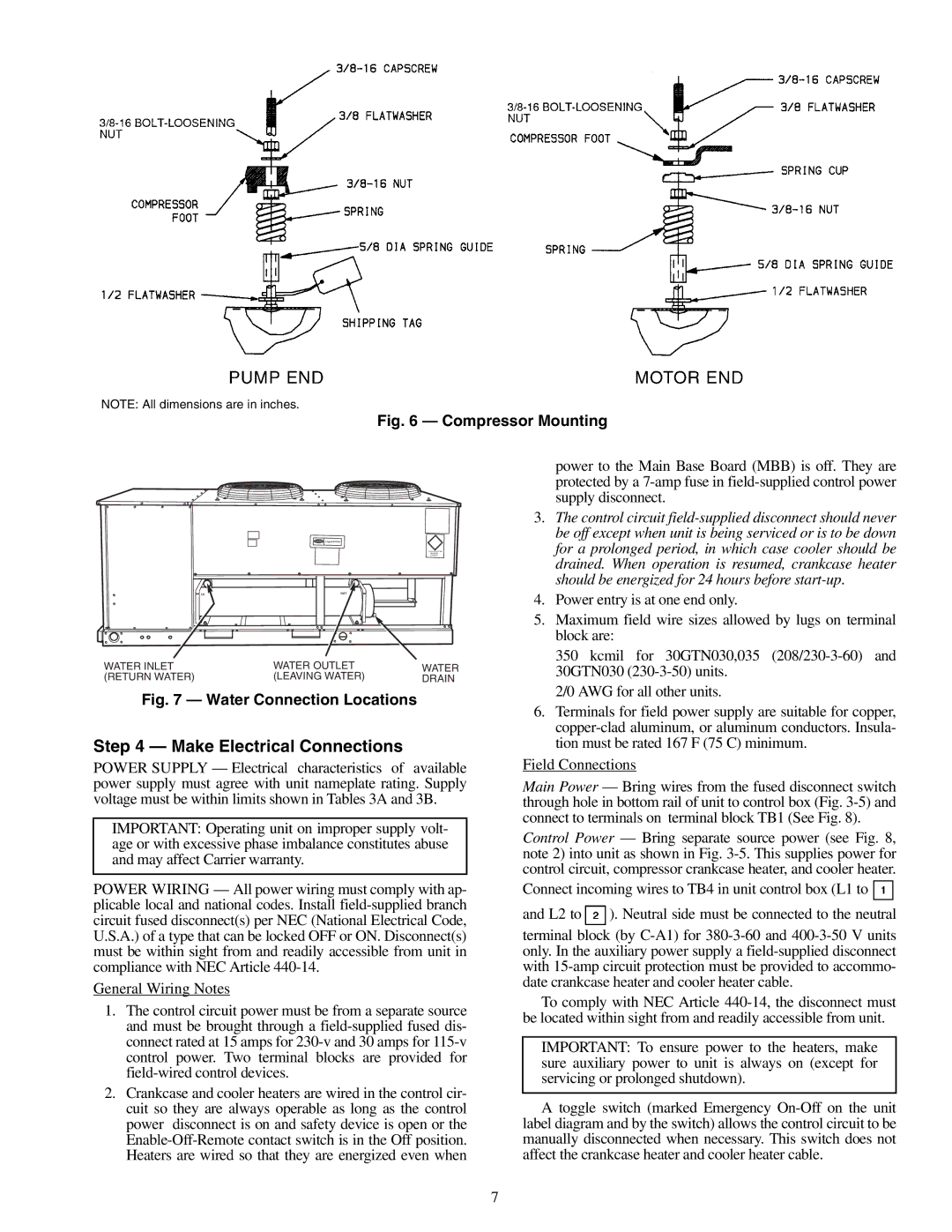

Fig. 6 — Compressor Mounting

power to the Main Base Board (MBB) is off. They are protected by a

3.The control circuit field-supplied disconnect should never

| be off except when unit is being serviced or is to be down |

U.N.2857 | for a prolonged period, in which case cooler should be |

REFRIGERATING |

|

MACHINE |

|

| drained. When operation is resumed, crankcase heater |

| should be energized for 24 hours before |

4. | Power entry is at one end only. | |

5. | Maximum field wire sizes allowed by lugs on terminal | |

|

| block are: |

|

| |

WATER | 350 kcmil for 30GTN030,035 | |

30GTN030 | ||

DRAIN |

| |

Fig. 7 — Water Connection Locations

Step 4 — Make Electrical Connections

POWER SUPPLY — Electrical characteristics of available power supply must agree with unit nameplate rating. Supply voltage must be within limits shown in Tables 3A and 3B.

IMPORTANT: Operating unit on improper supply volt- age or with excessive phase imbalance constitutes abuse and may affect Carrier warranty.

2/0 AWG for all other units.

6.Terminals for field power supply are suitable for copper,

Field Connections

Main Power — Bring wires from the fused disconnect switch through hole in bottom rail of unit to control box (Fig.

Control Power — Bring separate source power (see Fig. 8, note 2) into unit as shown in Fig.

POWER WIRING — All power wiring must comply with ap- plicable local and national codes. Install

General Wiring Notes

1.The control circuit power must be from a separate source and must be brought through a

2.Crankcase and cooler heaters are wired in the control cir- cuit so they are always operable as long as the control power disconnect is on and safety device is open or the

Connect incoming wires to TB4 in unit control box (L1 to ![]() and L2 to

and L2 to ![]() ). Neutral side must be connected to the neutral

). Neutral side must be connected to the neutral

terminal block (by

To comply with NEC Article

IMPORTANT: To ensure power to the heaters, make sure auxiliary power to unit is always on (except for servicing or prolonged shutdown).

A toggle switch (marked Emergency

7