Oil Pressure Safety Switch (OPS) Ð The OPS in the control circuit stops the compressor and unit, if proper oil pressure differential is not established at

Compressor Protection

CIRCUIT BREAKER Ð Calibrated trip manual reset, am- bient compensated, magnetic breaker protects against motor overload and locked rotor conditions.

CONTROL MODULE TIMER Ð This control protects com- pressor against short cycling. See Sequence of Operation on page 17.

CRANKCASE HEATER Ð This minimizes absorption of liquid refrigerant by oil in crankcase during brief or ex- tended shutdown periods.

IMPORTANT: Never open any switch or disconnect that deenergizes the crankcase heater unless unit is be- ing serviced or is to be shut down for a prolonged pe- riod. After a prolonged shutdown on a service job, en- ergize the crankcase heater for 24 hours before starting the compressor.

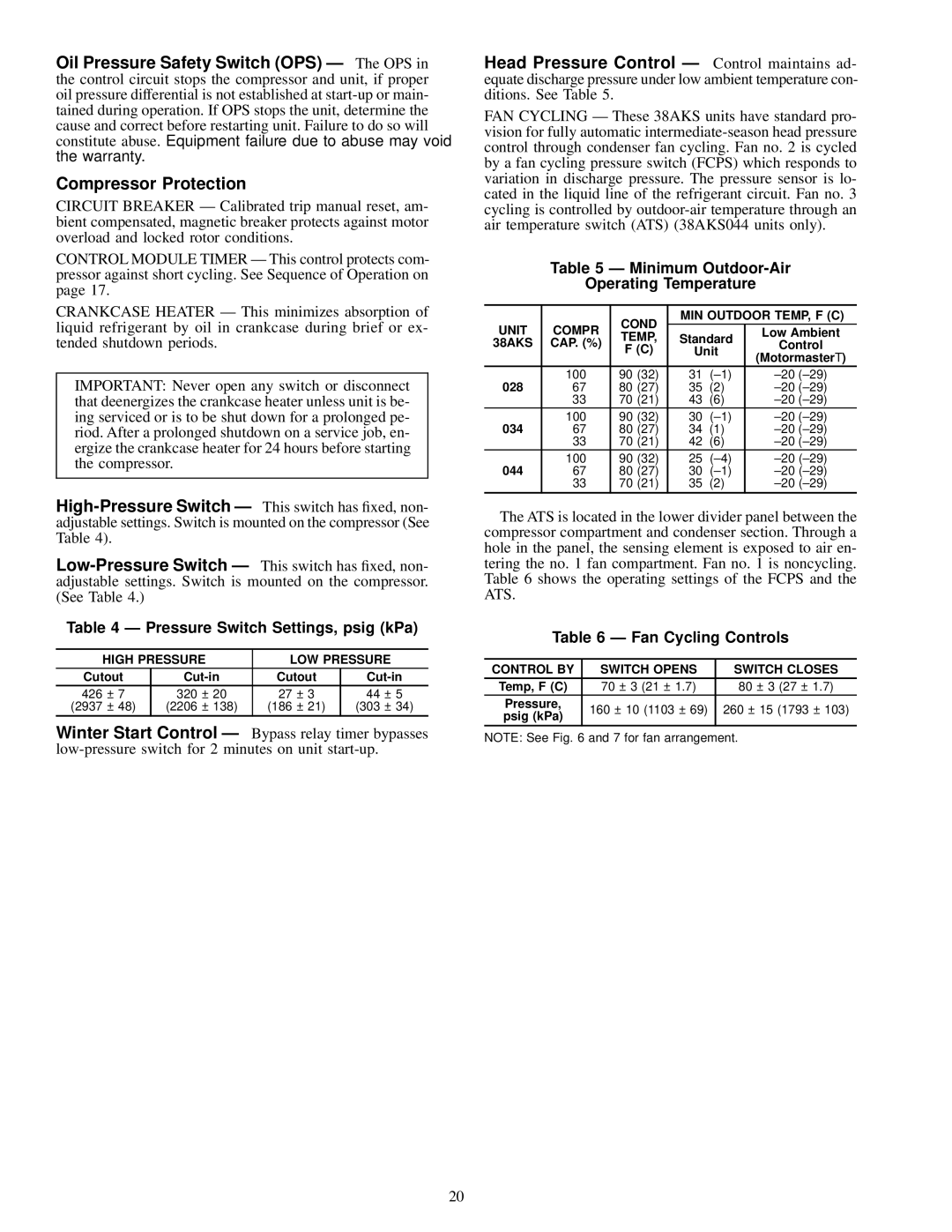

Table 4 Ð Pressure Switch Settings, psig (kPa)

| HIGH PRESSURE | LOW PRESSURE |

| |||||

Cutout | Cutout | |||||||

426 | ± 7 | 320 | ± 20 | 27 | ± 3 | 44 | ± | 5 |

(2937 | ± 48) | (2206 | ± 138) | (186 | ± 21) | (303 | ± | 34) |

Winter Start Control Ð Bypass relay timer bypasses

Head Pressure Control Ð Control maintains ad- equate discharge pressure under low ambient temperature con- ditions. See Table 5.

FAN CYCLING Ð These 38AKS units have standard pro- vision for fully automatic

Table 5 Ð Minimum Outdoor-Air

Operating Temperature

|

| COND | MIN OUTDOOR TEMP, F (C) | |||

UNIT | COMPR | TEMP, | Standard | Low Ambient | ||

38AKS | CAP. (%) | Control | ||||

F (C) | Unit | |||||

|

| (Motormaster ) | ||||

|

|

|

|

| ||

028 | 100 | 90 (32) | 31 | (±1) | ±20 (±29) | |

67 | 80 (27) | 35 | (2) | ±20 (±29) | ||

| 33 | 70 (21) | 43 | (6) | ±20 (±29) | |

034 | 100 | 90 (32) | 30 | (±1) | ±20 (±29) | |

67 | 80 (27) | 34 | (1) | ±20 (±29) | ||

| 33 | 70 (21) | 42 | (6) | ±20 (±29) | |

044 | 100 | 90 (32) | 25 | (±4) | ±20 (±29) | |

67 | 80 (27) | 30 | (±1) | ±20 (±29) | ||

| 33 | 70 (21) | 35 | (2) | ±20 (±29) | |

The ATS is located in the lower divider panel between the compressor compartment and condenser section. Through a hole in the panel, the sensing element is exposed to air en- tering the no. 1 fan compartment. Fan no. 1 is noncycling. Table 6 shows the operating settings of the FCPS and the ATS.

Table 6 Ð Fan Cycling Controls

CONTROL BY | SWITCH OPENS | SWITCH CLOSES | ||

Temp, F (C) | 70 ± 3 (21 ± 1.7) | 80 ± 3 (27 ± | 1.7) | |

Pressure, | 160 ± 10 (1103 ± 69) | 260 ± 15 (1793 | ± 103) | |

psig (kPa) | ||||

|

|

| ||

NOTE: See Fig. 6 and 7 for fan arrangement.

20